SPECIFICATIONS

1. Power input: 120VAC ±10%, 60 Hz, (240VAC ±10%, 50/60 Hz). 60 watts

2. Power unit output voltage: isolated 24VAC @ 2.7 amperes.

3. Size: 4.5 x 5.9 x 3.6

4. Line Cord: 3 wire, U.L. recognized

5. Tip temperature control range: 350°F to 850°F (177°C to 454°C).

6. Control setting resolution: 1°F (1°C).

7. Stability: ±10°F (±6°C) per Mil-Std-2000.

8. Absolute accuracy: Average tip temperature is calibrated to ±9°F (±5°C) at idle with no load.

9. Ambient temperature range: 60°F to 110°F (16°C to 44°C).

10. Housing made with Electrostatic Protective Material as required in MIL-B-81705.

11. Housing passes Static Decay test per Federal Test Method Std. No. 101, Method 4046.

12. Weller

®

ESD tools comply with DOD-HDBK-263.

13. EC2002 units are U.L. listed and meet DOD-STD-2000, MIL-STD-2000, MIL-S-45743, W-S-6536,W-S-570, DOD-STD-

1686.

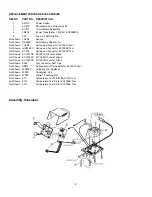

TROUBLESHOOTING GUIDE

WARNING:AC LINE VOLTAGE IS PRESENT INSIDE POWER UNIT EVEN WHEN POWER SWITCH IS OFF.

REFER SERVICE TO QUALIFIED PERSONNEL.

NOTE:

Access to internal parts may be gained by removing four rubber feet, four bottom screws and

top case.

2

Check wiring from tool receptacle to printed circuit board.

Repair or replace if defective.

Replace soldering tool with known good tool and recheck.

Troubleshoot soldering tool using guide in soldering iron tech sheet.

TOOL OVERHEATING

Replace soldering tool with known good tool and recheck.

Troubleshoot soldering tool using guide in soldering iron tech sheet.

Replace printed circuit board assembly in station.

TOOL DOES NOT HEAT DISPLAY NOT LIT

With line cord unplugged and power switch on, check for about 21 ohms at line cord blades for 120VAC units (55 ohms for

240VAC unit).

Check fuse, located on bottom of case replace if required. Use slow blow fuse 0.6A for 120VAC (0.3A for 240VAC).

Check power switch replace if defective.

Check line cord repair or replace if defective.

Check transformer primary replace transformer if defective.

With line cord plugged in and power switch on, check for 24VAC ±10% between pins #1 and #4 of tool receptacle.

Check transformer secondary for 24VAC ±10% - replace transformer if defective.

Check wiring to printed circuit board assembly repair or replace if defective.

Replace printed circuit board assembly.

With line cord plugged in and power switch on, check for 5 VDC ±1 VDC, between pins #3 and #4 of tool receptacle.

Replace printed circuit board assembly.

TOOL DOES NOT HEAT DISPLAY LIT