34

The funnel insert (16) for the soldering iron has four different

settings and can be moved to an ergonomically favourable

position without the use of tools. Areas have been provided

on the rear side (17) for depositing the soldering tip. The

pedestal plate of the rest contains a sponge insert (18) for

cleaning the soldering tips.

2.3. Soldering iron

WSP 80:

The WSP 80 soldering iron is characterised by fast

and precise achievement of the soldering tempera-

ture. Thanks to its slim design and a heat output of

80 W, universal application is possible, from extre-

mely fine soldering tasks to those which require

high temperatures.

WMP:

The Weller Micro Soldering Iron WMP is suitable for

processing professional SMD electronics due to its

manageable design. The short distance between

grip and soldering tip makes ergonomic handling of

the 65 W soldering iron possible when carrying out

very fine soldering tasks.

WTA 50:

The desoldering tweezers WTA 50 have been desi-

gned specially for unsoldering SMD components.

Two heating elements (2 x 25 W), each with its own

temperature sensor, guarantee the same tempera-

ture on both legs.

LR 82:

Powerful 80 W soldering iron for soldering tasks

with high heat requirements. The soldering tip is

secured by means of a bayonet catch, which ensu

res that tips are always in the correct position after

a change.

WSP 150:

Especially powerful 150 W soldering iron for sol-

dering tasks with extremely high heat require-

ments. Only one channel is active when this sol-

dering iron is used.

WMRP (only WD 2M):

Extremely powerful 40W fine soldering iron with

integrated heating technology in the soldering tip.

The soldering tip can be changed without the need

of tools thanks to a plug-in system. The soldering

tip temperature is reached extremely quickly and

is controlled precisely. Sensors built in to the

handle ensure that the soldering iron is switched

off automatically when placed down.

WMRT (only WD 2M):

Very manageable desoldering tweezers for precisi-

on SMD electronic devices. The soldering tip pair

can be changed as required without the use of

tools and can be used without additional

alignment of the soldering tips. The integrated 2 X

40W heating elements ensure that the soldering

tip temperature is reached very quickly and con-

trolled precisely. Sensors built in to the handle

ensure that the desoldering tweezers are switched

off automatically when placed down.

See Accessories for a list of other soldering tools that can be

connected.

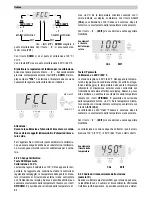

3. Commissioning

Take care when unpacking the unit and accessories. Place

the soldering tools in the safety rest. Insert the soldering iron

plug into the connection socket (9) and (10) of the control unit

and lock by turning slightly to the right. Check that the mains

voltage matches the specification on the identification plate

and that the mains switch (7) is switched off. Connect the

control unit to the mains (13). Switch on the unit at the mains

switch (7). The unit performs a self-test when it is switched

on, whereby all display elements (1) are in operation.

English

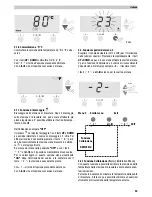

Temperatur display

Temperatur symbol

Time functions

Interlock

Visual control check

Special functions

3 Fixed temperatures

Temperature buttons

Displax Channel selection

Channel selection

Summary of Contents for WD 1M

Page 8: ...WD 2 ...

Page 9: ...WD 2M ...

Page 179: ...170 Setback function ...

Page 180: ...171 USB interface ...

Page 181: ...172 Exploded Drawing WD 2 WD 2 ...

Page 182: ...173 Circuit Diagram WD 2 ...

Page 183: ...174 Exploded Drawing WD 2M WD 2M ...

Page 184: ...175 Circuit Diagram WD 2M ...