32

Cooper Tools GmbH, Carl-Benz-Str. 2, 74354 Besigheim, P.O. Box 1351

Germany, Tel: (07143) 580-0, Fax: (07143) 580108

Because the adhesive strip is recessed, the placement of the component is not hindered. The component

that is to be soldered is placed on the template. The inner series of perforations (small openings) makes it

possible to centre the component precisely on the template.

The vacuum on the placement head will now be switched on. Lowering the placement head will cause the

component to be taken up and lifted from the metal template.

6

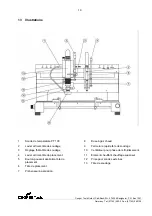

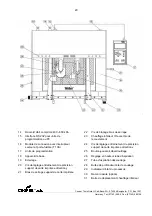

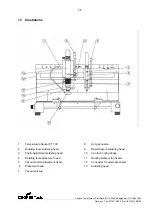

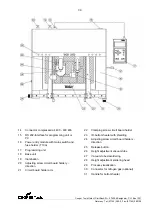

Module description - WQB 3000

6.1

Base unit

•

Stable, torsion-free welded construction made of steel plate profiles

•

Anti-static powder coating

•

Height-adjustable feet

•

Two horizontal, independently movable clamping arms with placement head and soldering head installed

on a precision linear guide

•

Pneumatic locking mechanism for both clamping arms, automatic activation via micro switch

•

Unlocks via key activation in the base unit

•

Two additional thermocouples (Type K) can be installed to determine temperature profile

•

Control electronics and pneumatic unit integrated in the rear housing on the table, tunnel-type duct for

extremely long circuit boards

•

Process status display via LED’s

•

Manual control panel can be connected for process activation

•

RS-232 interface for programming unit or PC control

6.2

Soldering head

•

Precision linear guide for Z adjustment, approx. 80 mm stroke

•

Infinitely adjustable depth stop with threaded spindle

•

Speed-controlled fan for cooling at end of process

•

Theta rotation of soldering head in range of -5° to 95°

•

Nozzle rapid closure

•

"Vacuum lift" for automatic de-soldering of components, height of vacuum tube is infinitely adjustable

with 10 mm adjustment range

•

Connection of temperature sensor for hot gas nozzle in the soldering head

•

Heating element with max. 700 W rating

•

Shock-absorbed lowering of the soldering head

•

Encased construction for industrial applications

•

Swivelling halogen light

6.3

Placement head:

•

Precision linear guide for Z adjustment, approx. 80 mm stroke

•

Lowering of placement head with shock absorption

•

Intelligent design - all incoming lines are protected and encased

•

Activation of vacuum pickup by key on front of placement head

•

Reducer insert of vacuum pickup for small components

•

Swivelling halogen light