14

Thank you for placing your trust in our company by pur-

chasing the WELLER WFE 20D soldering fumes extractor.

Production was based on stringent quality requirements

which guarantee the perfect operation of the device.

1. Caution!

Please read these Operating Instructions and the attached

safety information carefully prior to initial operation. Failure

to observe the safety regulations results in a risk to life and

limb.

The manufacturer shall not be liable for damage resulting

from misuse of the machine or unauthorised alterations.

The WELLER WFE 20D soldering fumes extractor corre-

sponds to the EC Declaration of Conformity in accordance

with the basic safety requirements of Directives

2004/108/EC and 2006/95/EC + 2004/42/EC.

2. Description

The WELLER Soldering Fume Extraction Device WFE 20D has

a powerful maintenance-free turbine, making is perfectly

suited to continuous operation in industry. The unit was

designed for direct extraction at the soldering iron and is

suitable for surface extraction.

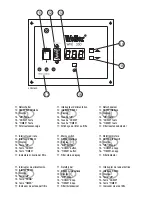

A digital electronics system allows simple and convenient

operation of the available functions. The vacuum created by

the turbine is controlled in standard mode (

mode 0

) elec-

tronically to the preset value of 8.000 Pa. This value can be

changed individually in

mode 2.

If low extraction power is sufficient, the control setpoint can

be reduced in

mode 2.

If mode 2 has been set, the unit must

be switched over to the desired operating mode to prevent

an inadvertent change of the setpoint value. In addition, the

turbine speed can be changed manually in speed-controlled

mode 1

in the range 20% - 100%.

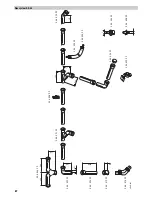

For connection to the pipe system DN40, a max. of 2 vacu-

um connections (3) are available. The pipe system can be

arranged individually by positioning the vacuum connections

(plug-in nipples) for the soldering irons (max. 20) as

required. Alternatively, 5 vacuum connections are provided

directly on the unit for soldering iron fume extraction.

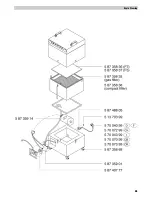

The standard composition of the installed 3-stage filter (fine

dust filter, HEPA filter and wide-band gas filter) is specially

adapted to soldering fumes. With the use of the type-tested

HEPA filters in Class H13, the separation rate of the filter set

upon delivery is 99.95% as per EN 1822 with a particle size

of 0.12 m. These figures are only achieved with the use of

original parts. A required filter change is indicated by a dis-

play of a differential pressure measurement on the unit.

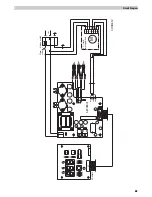

Using a standard RS232 interface, all of the unit's functions

can be operated and remotely controlled. An operating hours

code and operating hours specification widen the scope of

the unit's functions.

3. Commissioning

Direct interconnection of the FE soldering bits

The WELLER WFE 20D soldering fume extractor is fitted out

for the direct interconnection of a maximum of 5 WELLER FE

soldering bits. To connect up the vacuum hose, first remove

the sealing lid and then push the hose directly onto the push-

on nipple (4). The FE soldering bit unit uses a vacuum hose

that is 2.5 m long. If the soldering stations are further away

(up to 5 m), a DN17 extension hose can be used (this can be

obtained as an accessory). Push-on nipples must be fitted to

the end of the DN17 hose and the unit.

Indirect interconnection via a DN40 hose system

(accessory)

The WELLER WFE 20D is interconnected to the vacuum hose

system via a flexible fume extraction hose NW44 for indirect

operation. In this case the 5 push-on nipples (4) remain

sealed and the sealing plug (3) for the hose system has to be

removed. In order to connect up the hose system for the FE

English

Technical data

Dimensions L X W X H:

450 mm X 450 mm X 695 mm

Weight: 45

kg

Voltage: 230

V/50

Hz

Electrical power rating:

630 VA

Vacuum (controlled):

8,000 Pa

Maximum quantity supplie:

100 m

3

/h

Noise emission level:

51 dB(A)

Filter:

Stage 1

Pre-filter F5

Stage 2; 3

Class H13 high efficiency sub-micron particle air filter

(99.95% particles up to approx. 0.12 µm)

combined with a wide-band gas filter

(50% AKF, 50% Puratex)

Summary of Contents for Zero-Smog WFE 20D

Page 3: ...WFE 20D...

Page 9: ...66 Explo Drawing...