INSTALLATION

5

3.

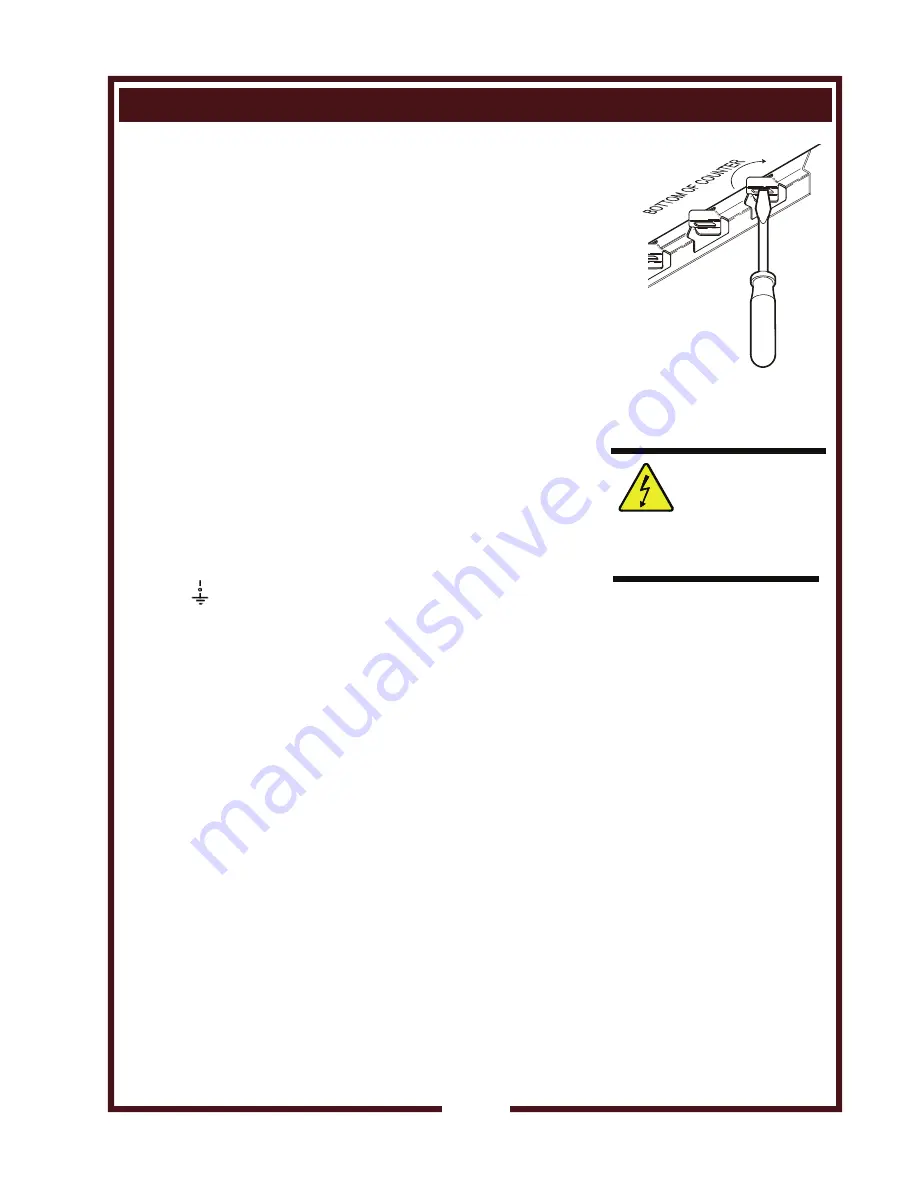

For “top-mounted” warmers (i.e. warmers mounted from above

the

counter

top):

a. Verify that provided sealants are applied to the underside

of the warmer top flange prior to setting the unit into the

cutout.

b.

After

installation,

verify

that the tabs on the Wellsloks are

turned out to lock the warmer into the counter

c. Apply a thin bead of food-grade silicone sealant around the

flange to seal it to the counter.

d. Wellslok extension kits are available for installing warmers

in counter tops where the standard Wellslok would not

normally reach. The extension kit will adapt to counter

tops up to 1¾” thick.

ELECTRICAL INSTALLATION

1. Refer to the product nameplate. Verify the electrical service

power. Voltage and phase must match the nameplate

specifications. Wiring the warmer to the wrong voltage can

severely damage the unit or cause noticeably decreased

performance.

2. Available electrical service amperage must meet or exceed the

specifications listed on the specification sheet provided with the

warmer.

3. Warmer and control unit must be connected to an appropriate

building ground. Ground connection will be marked “GND” or

” " .

NOTE:

Wire gauge, insulation type and temperature rating , as

well as type, size and construction of conduit, must meet or exceed

applicable specifications of local codes and of the National

Electrical

Code.

E. PLUMBING

INSTALLATION

For use in the State of Massachusetts, this appliance must be

installed in compliance with

Massachusetts Fuel Gas and

Plumbing Code CMR 248.

1.

IMPORTANT:

All plumbing installations must be performed by

a

qualified

plumber.

2. AUTOFILL units are equipped with a DRAIN LINE: Some

jurisdictions may require an approved air gap or other

back-flow prevention device in the drain. It is the responsibility

of the plumber to determine such requirement, to provide and

properly install the required device.

3. For AUTOFILL units: Some jurisdictions may require an

approved back-flow preventer in the water supply line. It is the

responsibility of the plumber to determine such requirement,

and to provide and properly install the required device.

Autofill supply must be connected to a COLD WATER line only.

NOTE:

Damage caused by

leaks due to improper

installation is NOT covered by

warranty.

CAUTION:

SHOCK HAZARD

The ground lug of this

appliance must be connected

to a suitable building ground.

IMPORTANT:

Contact a licensed electrician

to install and connect

electrical power to the

appliance.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

IMPORTANT:

Electrical

installation other than as

specified on the specification

sheet will void the UL listing,

and may void the warranty.

NOTE:

Plumb connections

must be made in compliance

with all Federal, State and

Local Plumbing Codes and

Ordinances.

M

011C.12 2M

-308023

Owne

rs M

anual fo

r B

uilt-

In

Doubl

e-

W

ell

Au

to-Fill

M

odular

W

armer

s