D. NATURAL GAS / LP GAS (PROPANE) CONVERSION

1. This fryer is orificed at the factory for natural gas at a pressure of 3.5” of water column.

The installed orifice is suitable for use at -280 to 2999 feet (-85 to 914 meters) elevation.

It is the responsibility of the installer to install the factory recommended orifice and pressure

regulator kit suitable for the fuel type and elevation at the final installation site.

2. The red tag (p/n 301217) attached to the gas connection provides pressure settings and part

numbers for conversion kits applicable to various fuels and altitudes.

3. The natural gas altitude conversion kit contains

two orifices.

Both orifices must be changed

.

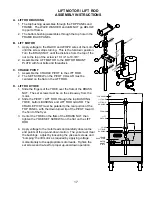

Be sure to use a back-up wrench when

changing orifices to avoid bending the

orifice bracket on the burner tube.

Be sure to check operating pressures on both

burner systems after the orifices have been

changed.

4. The LP gas (propane) conversion set contains

two orifices and two gas valve regulator kits.

Both orifices must be changed, and both

gas valve regulators must be converted

.

Complete instructions are included in the

regulator conversion kits. Be sure to check

and adjust operating pressures on both burner

systems after the orifices have been changed

and the regulators have been converted.

NOTE:

Failure to install proper orifices can potentially cause burner and flue system failure.

Damaged caused by improper orifice installation is NOT covered by warranty.

E.

FLAME ADJUSTMENT

1. A proper flame will have a bright blue, well defined inner cone, and a strong,

light blue outer cone with only a very little yellow along the outermost edges.

2. Too much yellow indicated a rich flame. Adjust by opening the shutter or

decreasing the orifice size (see tag p/n 301217 for proper orifice size for the

installation altitude).

3. No yellow and a very small inner cone indicates a lean flame. Adjust by

closing the shutter or increasing the orifice size (see tag p/n 301217 for

proper orifice size for the installation altitude).

7

REGULATOR SEAL SCREW

(USE NEW ITEM FROM KIT)

REGULATOR SPRING

(USE NEW ITEM FROM KIT)

ADJUSTMENT SCREW

(REUSE EXISTING ITEM)

BURNER

TUBE

OUTER

CONE

INNER

CONE

35. ORIFICE HOLDER

6. ORIFICE WASHER

8. or 27. BURNER

14. ORIFICE

NOTE: ORIFICE

SIZE MARKING

PLACE BACK-UP WRENCH ON THIS

SIDE WHEN CHANGING

ORIFICE

PLACE BACK-UP WRENCH ON THIS SIDE

WHEN TIGHTENING

GAS SUPPLY TUBE