To fill the fuel tank

1. Clean the area around the fuel tank cap.

2. Shake the container and make sure that the fuel is

fully mixed.

3. Fill the fuel tank.

4. Tighten the fuel tank cap carefully.

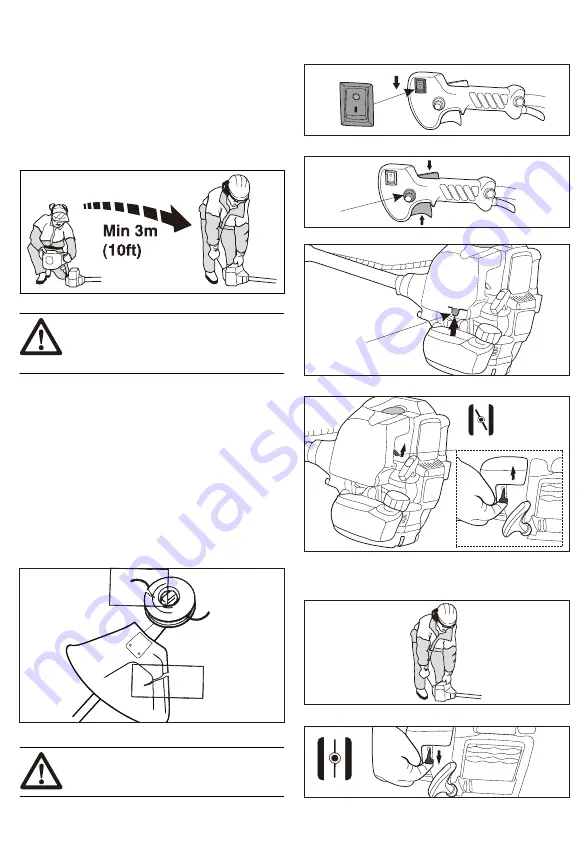

5. Move the product 3 m (10 ft) or more away from the

refueling area and fuel source before starting.

CAUTION: Contamination in the tanks

causes malfunction. Clean the fuel tank

regularly and replace the fuel

filter

one

time a year or more.

Before you operate the product

• Examine the work area to make sure that you know

the type of terrain. Examine the slope of the ground

and if there are obstacles such as stones, branches

and ditches.

• Do an overhaul inspection of the product.

• Do the safety inspections, maintenance and

servicing that are given in this manual.

• Make sure that all covers, trimmer guard and

trimmer head correctly attached and not damaged or

cracked. Replace if they are exposed to impact or

cracked.

WARNING: Do not use the product without a

guard or a guard that is defective.

To

start

a cold engine

3

. Push the air

primer

bulb

6

-

10

times

.

4

. Move the choke control up into choke

on

position.

Primer Bulb

1

.

Open the engine (I-open/o-stop )

5

.

Pull the starter rope until the engine warm up .

6

.

Push the choke control down into the choke off .

Warm up ( Engine start / Try to start ) .

14

Pull Max 6 times .

2

.

Hold

the

trigger

and

trigger

lockout

press

the

lock

button

.

lock

button

Summary of Contents for WS-ST42G

Page 1: ...WS ST42G...

Page 21: ...X 15CM 6 Click 10 20 9 21...