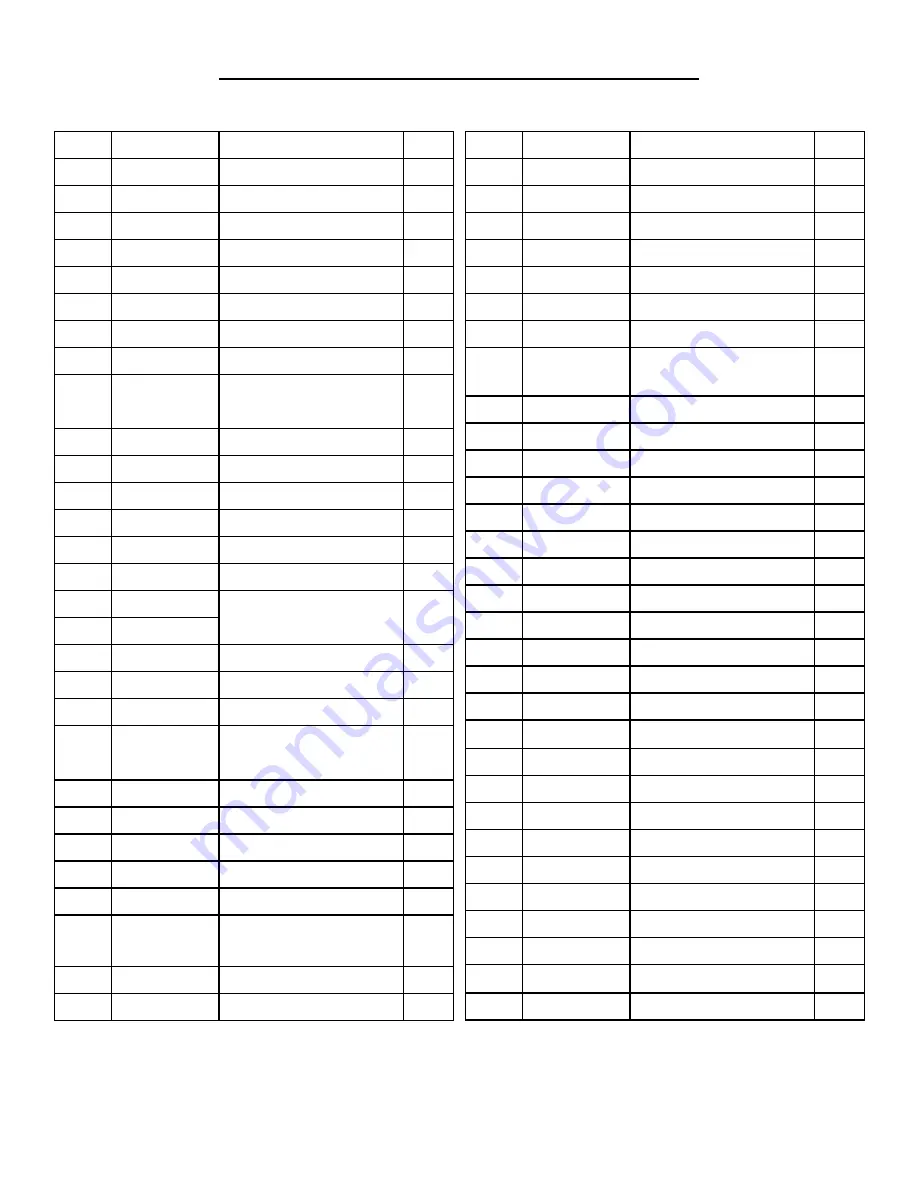

EXPLODED VIEW & PARTS LIST

No.

Part No.

Description

Qty.

1

36725-001

Right Handle

1

2

36725-002

Line Pressing Board

1

3

36725-003

Screw ST4x16

9

4

36725-004

Switch

1

6

36725-006

Power Cord Sheath

1

7

36725-007

Left Handle

1

8

36725-008

Screw ST4X25

4

9

36725-009

Housing Cover

1

10

36725-010

Carbon Brush

Protector

2

11

36725-011

Housing

1

12

36725-012

Stator Assembly

1

13

36725-013

Screw ST4x65

2

14

36725-014

Fan Shroud

1

15

36725-015

Bearing 608

1

16

36725-016

Brush Holder

2

17

36725-017

Carbon Brush

2

18

36725-018

19

36725-019

Rotor Assembly

1

20

36725-020

Bearing 6000

1

21

36725-021

Rubber Column

1

22

36725-022

Depth Locking

Screw

1

23

36725-023

Left Aluminum Head

1

24

36725-024

Retaining Washer

1

25

36725-025

Screw M6x14

1

26

36725-026

Screw M6x16

1

27

36725-027

Oil Bearing

1

28

36725-028

Dust Port Adapter

1.5” O.D.

1

29

36725-029

Gear

1

30

36725-030

Main Shaft

1

No.

Part No.

Description

Qty.

31

36725-031

Elastic Cylindrical Pin

1

32

36725-032

Retaining Ring

1

33

36725-033

Bearing 6001

1

34

36725-034

Bearing Base

1

35

36725-035

Screw M4x12

4

36

36725-036

Spring

1

37

36725-037

Screw ST4x10

1

38

36725-038

Lower Blade Guard

Lever

1

39

36725-039

Protection Guard Knob

1

40

36725-040

Coil Spring

1

41

36725-041

Inner Flange

1

42

36725B

Blade

1

43

36725-043

Outer Flange

1

44

36725-044

Washer

1

45

36725-045

Screw M8x14

1

46

36725-046

Right Aluminum Head

1

47

36725-047

Screw M5x12

3

48

36725-048

Rivet Screw

2

49

36725-049

Base Washer

2

50

36725-050

Depth Guide Bracket

1

51

36725-051

Rip Guide Lock Knob

1

52

36725-052

Base

1

53

36725-053

Bevel Locking Knob

1

54

36725-054

Retaining Ring

1

55

36725-055

Screw 5.5xM5x12

1

56

36725-056

Angle Brackets

1

57

36725-057

Connecting Pin

1

58

36725-058

Spindle Lock Spring

1

59

36725-059

Spindle Lock

1

60

36725-060

Parallel Guide

1

61

36725-061

Hex Wrench M6

1

19

Summary of Contents for 36725

Page 18: ...18 EXPLODED VIEW PARTS LIST ...

Page 20: ...THANKS FOR REMEMBERING ...