Air Hose

Quick Connector

Air Supply

Regulator

Lubricator

Filter

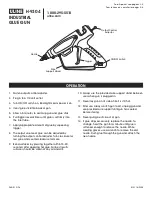

PREPARING THE AIR SUPPLY (Fig. 2)

WARNIN

G: Use only clean, dry and regulated air. NEVER use oxygen combustible gases, bottled

gases or high pressure compressed gas to power this tool. Danger of explosion and serious personal

injury may result.

Your nailer is designed to operate on dry compressed air at the regulated pressure between 70 and 120 PSI (4.8

and 8.3 bar). Do not operate when the air pressure is outside of the recommended range. The recommended

air supply setup should include the following:

• A pressure regulator - to regulate the air pressure

• An in-line filter - to remove contaminants from the air

• An in-line automatic oiler - to keep the tool lubricated

The oiler should be located as close to the tool as possible, within 15 feet is ideal. If an in-line oiler is not avail-

able, place five or six drops of oil into the tool’s air inlet and the beginning of each work day as shown in Fig. 1.

All air supply components including hoses, connectors, filters, regulators, etc. must have a working pressure rat-

ing of at least 180

PSI (150% above the maximum operating pressure of the tool) . Refer to the diagram below

(Fig. 2) for the recommended accessories and connection order.

Fig. 2

PREPARATION AND ADJUSTMENTS

LUBRICATING THE TOOL (Fig. 1)

This tool requires lubrication before each use (especially the first use). Proper lubrication is the owner’s respon-

sibility. Failure to lubricate the tool properly will dramatically shorten the life of the tool and void the warranty.

Fig. 1

Oil

NOTE:

An automatic in-line oiler is a convenient way to provide

oil to the tool. If an in-line oiler is installed, manual lubrication

through the air inlet is not required.

1. Make sure the tool is disconnected from the air supply.

2. Turn the tool so the air inlet is facing up. Place 5 to 6 drops of

resin-free 30W non-detergent air tool lubrication oil into the air

inlet (Fig. 1). Excessive lubrication may damage the work surface.

Wipe off any excess oil from the inlet.

WARNING:

To prevent injury from accidental operation, make sure the tool disconnected from the

air supply before assembly and making adjustments. Always wear Z87.1-approved safety glasses and

hearing protection during assembly, operation, and maintenance of the tool.

8

Summary of Contents for 61731

Page 18: ...EXPLODED VIEW PARTS LIST 18...