6

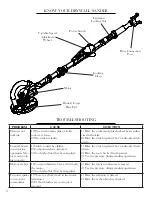

KNOW YOUR DRYWALL SANDER

Variable Speed

Adjustment

Wheel

Power Switch

Hose Connection

Port

Motor

Hook & Loop

Base Pad

Locking

Clasp

PROBLEM

CAUSE

SOLUTION

Motor is not

working.

1) Wires in the main plug or in the

socket are loose.

2) The switch is faulty.

1) Have the socket and plug checked by an autho-

rized technician.

2) Have the switch replaced by an authorized tech-

nician.

Unusual noises

occur during

operation. Mo-

tor is not work-

ing properly.

1) Switch contact has failed.

2) Components have jammed.

3) Too high of load has been applied.

1) Have the switch replaced by an authorized tech-

nician.

2) Have the tool checked and repaired.

3) Use less pressure during sanding operations.

Motor gets hot. 1) Foreign substances have gotten inside

the motor.

2) Too high of load has been applied.

1) Have the foreign substances removed.

2) Use less pressure during sanding operations.

Frequent sparks

occur on the

commutator.

1) There is a short circuit in the motor

(armature).

2) Carbon brushes are worn out or

jammed.

1) Have the armature replaced.

2) Have the carbon brushes checked.

TROUBLESHOOTING

Extension

Locking Nut

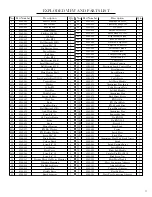

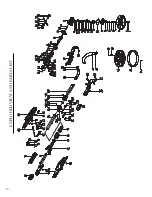

Summary of Contents for 6369

Page 10: ...10 EXPLODED VIEW AND PARTS LIST...

Page 12: ...Thanks for remembering...