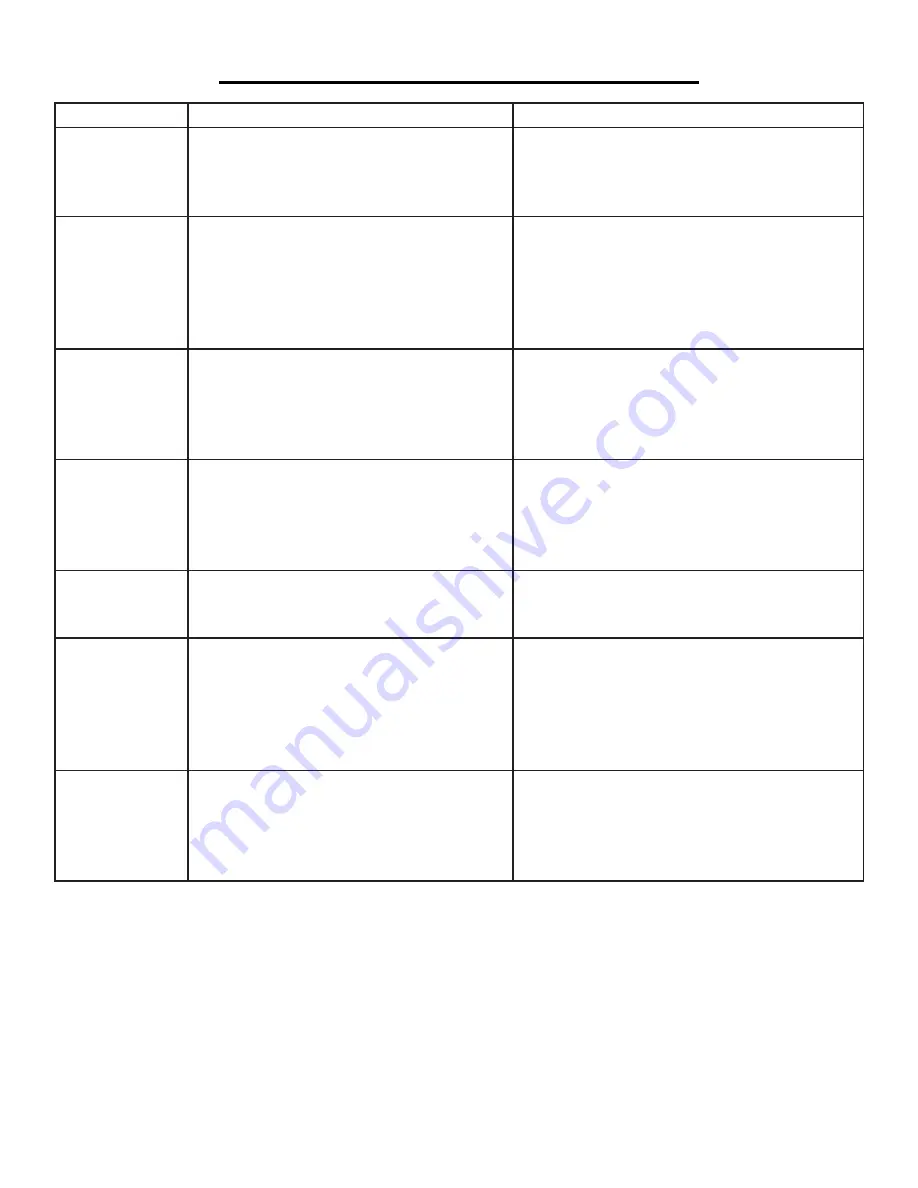

PROBLEM

CAUSE

SOLUTION

Sanding grains

easily rub off

belt or discs

1) Sanding belt/disc has been stored in an

incorrect environment.

2) Sanding belt/disc has been damaged or

folded.

1) Store sanding accessories away from ex-

tremely hot/dry temperatures.

2) Store sanding accessories flat—not bent or

folded.

Deep sanding

grooves or scars

in workpiece.

1) Sanding belt/disc grit is too coarse for the

desired finish.

2) Workpiece sanded across the grain.

3) Too much sanding force on workpiece.

4) Workpiece held still against belt-disc for

too long.

1) Use a finer-grit sanding accessory.

2) Sand with the grain of the wood.

3) Reduce pressure on workpiece while sand-

ing.

4) Keep workpiece moving while sanding on

the sanding accessory.

Sanding surface

clogs quickly

1) Too much pressure against belt/disc

2) Sanding softwood.

1) Reduce pressure on workpiece while sand-

ing.

2) Use different stock/sanding accessories, or

accept that this will happen and plan on clean-

ing or replacing belts/discs frequently.

Burns on work-

piece

1) Use a sanding grit that is too fine.

2) Using too much pressure.

3) Work held still for too long.

4) Sanding disc/belt loaded with debris.

1) Use a coarser-grit sanding accessory.

2) Reduce sanding pressure on workpiece

3) Do not keep workpiece in one place for too

long.

4) Clean or replace the disc or belt.

Sander does not

turn on

1) Not plugged in to an electrical outlet

2) Defective power switch

3) Motor or wiring problem

1) Connect the unit to an outlet.

2) Replace the switch.

3) Have a qualified technician make repairs.

Motor will not

start—fuses or

circuit breakers

tripping/blowing

1) Short circuit in line, cord or plug.

2) Short circuit in motor or loose connec-

tions

3) Incorrect fuses or circuit breakers in

power line.

1) Inspect cord or plug for damaged insulation

and shorted wires.

2) Inspect all connections on motor for loose

or shorted terminals and/or worn insulation.

3) Install correct fuses or circuit breakers or

switch tool to an appropriately sized circuit.

Motor overheats 1) Motor overloaded

2) Extension cord too long with an insuf-

ficient gauge.

1) Reduce load on motor (pressure on object

being sanded)

2) Utilize an extension cord of appropriate

gauge and length or plug tool directly into

outlet.

TROUBLESHOOTING

15