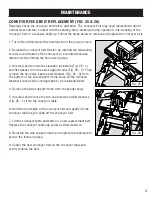

PREPARATION

PLANNING YOUR WORK

Planning your work before operation will help to save time and minimize setups. Group your

workpiece by thickness and grit requirements. Work through each required sanding grit from the

thickest to the thinnest material. Then, change to a finer grit sandpaper and work through the

process again.

WARNING:

To avoid injury from accidental startups, always ensure that the tool is switched

OFF and unplugged from the power supply before making adjustments.

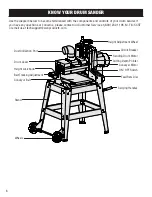

INTRODUCTION

The drum sander is a machine designed to sand wooden workpieces to a desired thickness and

smoothness. Before adjusting and operating the machine, it is important to know that drum sanding

is different from thickness planing. Drum sanding can only remove material in increments of 1/32

inch (0.8mm) or less, depending on the sanding grit, material hardness, sanding width, etc. The drum

sander is not suitable for quick bulk material removal. Forcing your drum sander to remove too much

material too fast will cause damage to your machine and the workpiece.

WORKPIECE INSPECTION

This drum sander is intended for sanding natural and man-made wood materials. This machine

cannot sand other materials such as metal, glass, stone, tile, etc. Make sure to inspect all workpieces

before operation and refer to the list below for materials that you should avoid or take extra care with.

FOREIGN OBJECTS. Foreign objects such as nails, staples, dirt, rocks, etc. are often embedded in wood. The

objects may cause kickback that can hit the operator and damage the machine. Remove those foreign objects

before operation.

LARGE OR LOOSE KNOTS. Choose workpieces that do not have large or loose knots. Large knots may cause

kickback and damage the machine. Loose knots in stock can become dislodged during sanding operations.

WOOD SPECIES WITH TOXIC PROPERTIES. Wood species such as the rosewood family (e.g. cocobolo) have toxic

properties that may result in allergic reactions. Even with dust control, you may inhale small airborne particles and

possibly suffer an allergic reaction.

HIGHLY RESINOUS SPECIES. Highly resinous species tend to quickly clog or load up sandpaper easily. This

includes some common pine species. It is almost impossible to clear the sandpaper of the pitch and sawdust from

those species of wood. Avoid sanding those wood species or make sure to replace sandpaper often.

WET OR GREEN STOCK. Wood stock with a moisture content over 20% causes excessive wear on the sandpaper

and motors as you’re sanding. This may increase the risk of kickback and result in a poor surface finish. Use stock

with moisture content below 20%.

EXCESSIVE WARPING. Do not sand workpieces with excessive warping or twisting as they are unpredictable and

difficult to hold stable. DO NOT sand workpieces with excessive warping.

Continues on page 18

17

Summary of Contents for 65911

Page 35: ...35 NOTES ...

Page 36: ...THANKS FOR REMEMBERING ...