ASSEMBLY & ADJUSTMENTS

ADJUSTING THE WORK TABLE BEVEL

The work table has the capacity to tilt from 0 to 45 degrees

for sanding bevels on your workpiece. For any bevel sand-

ing operation, you must use throat plate with an oblong-

shaped opening.

To adjust the table bevel:

1. Disconnect the machine from the power source.

2. Loosen the table bevel knobs (Fig. 3 - 1) on both sides

of the sander.

3. Tilt the table until the pointer is indicating the desired

angle on the bevel gauge.

4. Re-tighten both bevel knobs.

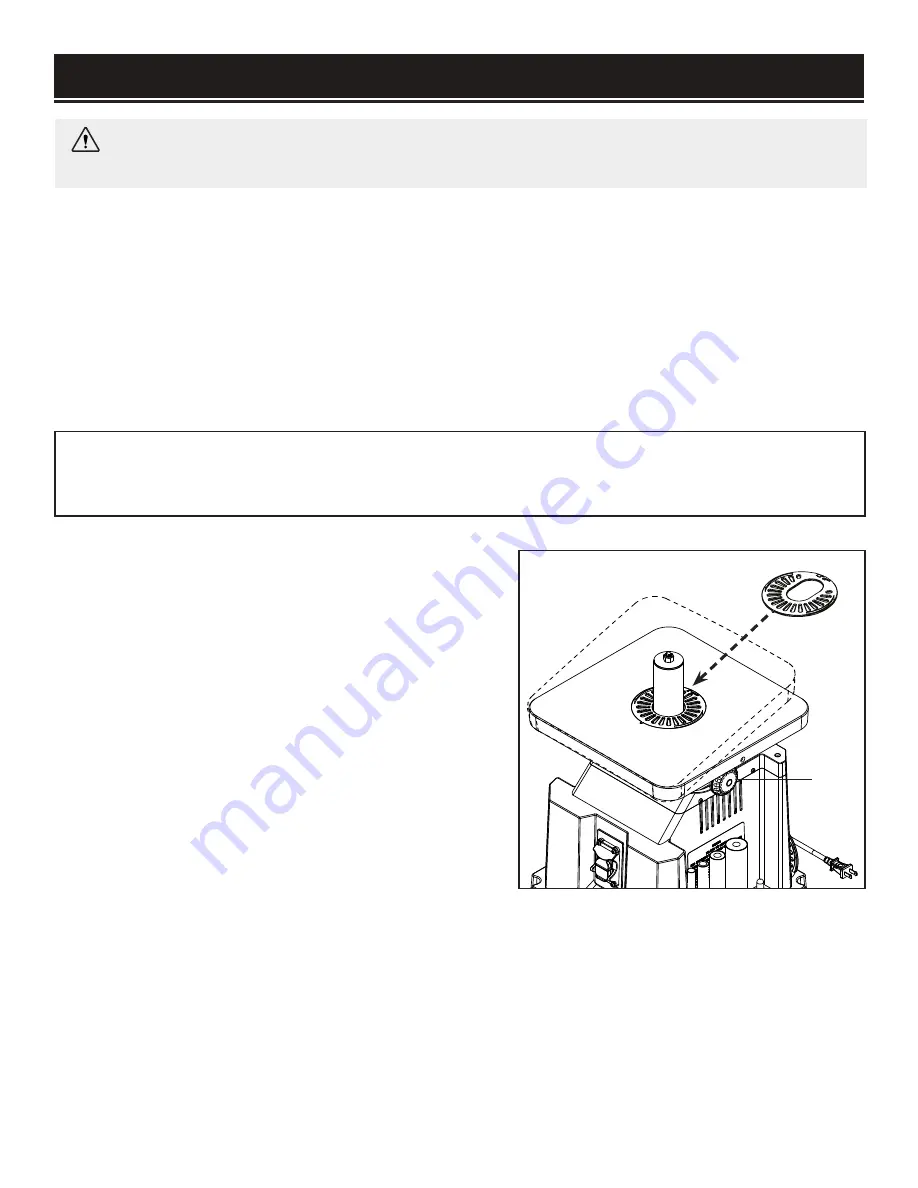

MACHINE MOUNTING

For safe operation, the machine must be secured onto a flat, secure workbench or stand. The base of the ma-

chine has four 6 mm mounting holes. Place the sander on the mounting surface, and insert a pencil through

the mounting holes to mark the hole locations. Remove the sander and drill out the mounting holes. Then align

the sander base over the mounting holes and secure the machine using four mounting bolts, washers, locking

washers and hex nuts (mounting hardware not included). Securely tighten the hex nuts.

For temporary mounting, secure the sander to a mobile mounting board and use 2 large C-Clamps to secure

the mounting board to a solid surface.

TIP:

Your spindle sander is compatible with the

WEN 6588

Multipurpose Planer Stand, available at

wenproducts.com

. Forget measuring and drilling holes on your workbench, simply mount your machine

onto the stand with pre-drilled holes, and transport your machine around the workshop with ease.

Fig. 3

1

12

WARNING:

To prevent accidental starting, make sure the machine is switched OFF and the power

plug is disconnected before assembly, setting up or making adjustments.