ASSEMBLY & ADJUSTMENTS

SQUARING THE TABLE TO THE SPINDLE

When sanding with the work table in the horizontal (0°) position, make sure that the table surface is square to

the sanding spindle. With the sanding drum and sleeve installed, check the alignment using a machinist's or

combination. The square should be flat against the table and the spindle (Fig. 4). Periodically check for proper

alignment between the table and spindle. If the table and spindle are not square, adjust as follow:

DUST COLLECTION

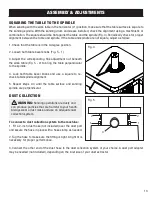

1. Check that the table is in the 0-degree position.

2. Loosen both table bevel knobs (Fig. 5 - 1).

3. Adjust the corresponding fine adjustment nut beneath

the work table (Fig. 5 - 2) to bring the table perpendicular

to the spindle.

4. Lock both table bevel knobs and use a square to re-

check table/spindle alignment.

5. Repeat steps 2-4 until the table surface and sanding

spindle are perpendicular.

Fig. 4

Fig. 5

WARNING:

Sanding operations are dusty and

can produce particles that are harmful to your health.

Always wear a dust mask and use an adequate dust

collection system.

To connect a dust collection system to the machine:

1. Fit a 2-inch dust hose (not included) over the dust port

and secure the hose in place with a hose clamp as needed.

2. Tug the hose to make sure the fitting is tight. A tight fit is

necessary for proper performance.

2

1

2

1

3

3. Connect the other end of the dust hose to the dust collection system of your choice. A dust port adapter

may be needed (not included), depending on the inlet size of your dust extractor.

13