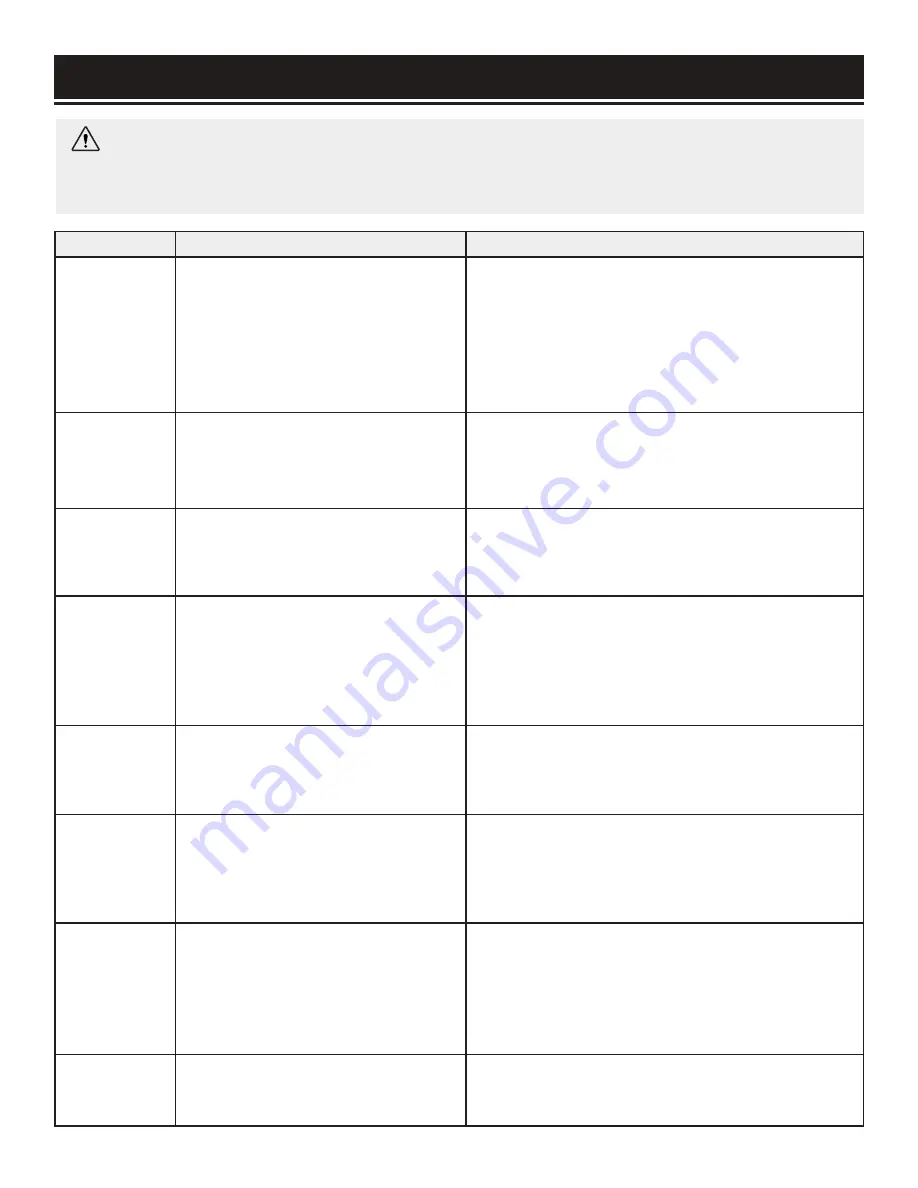

PROBLEM

CAUSE

SOLUTION

Sander does

not turn on

1. Power cord or extension cord dam-

aged or not properly plugged in.

2. Safety key is removed from power

switch.

3. Defective power switch, defective

motor or wiring, short circuit or loose

connections.

1. Check the power cord, extension cord, power plug

and the power outlet. Make sure the tool is properly

plugged in. Do not use the if any cord is damaged.

2. Insert the safety key into the power switch.

3. Stop using the tool and contact customer service

at (800) 232-1195, M-F 8-5 CST for assistance. Re-

pairs must be done by a qualified technician.

Motor

overheats

1. Motor overloaded.

2. Extension cord too long with an

insufficient gauge.

1. Reduce load on motor - reduce pressure on the

workpiece being sanded.

2. Utilize an extension cord of appropriate gauge and

length or plug tool directly into outlet (see page 8).

Sanding grains

easily rub off

1. Sanding sleeve has been stored in

an incorrect environment.

2. Sanding sleeve has been damaged

or folded.

1. Store sanding accessories away from extremely

hot/dry temperatures.

2. Store sanding accessories flat—not bent or folded.

Deep sand-

ing grooves

or scars in

workpiece.

1. Sanding sleeve grit is too coarse for

the desired finish.

2. Workpiece sanded across the grain.

3. Too much sanding force.

4. Workpiece held still against sanding

surface for too long.

1. Use a finer-grit sanding accessory.

2. Sand with the grain of the wood.

3. Reduce pressure on workpiece while sanding.

4. Keep workpiece moving while sanding on the

sanding sleeve.

Burns on

workpiece

1. Using a sanding grit that is too fine.

2. Using too much pressure.

3. Work held still for too long.

4. Sanding sleeve loaded with debris.

1. Use a coarser-grit sanding accessory.

2. Reduce sanding pressure on workpiece.

3. Do not keep workpiece in one place for too long.

4. Clean or replace the sanding sleeve.

Sanding

surface clogs

quickly

1. Too much pressure against sleeve.

2. Sanding softwood.

1. Clean sanding sleeve. Reduce pressure on work-

piece while sanding.

2. Use different stock/sanding accessories, or accept

that this will happen and plan on cleaning or replac-

ing sleeves frequently.

Sander

vibrates

excessively

or has noisy

operation.

1. Sanding sleeve out of balance or is

loose.

2. Motor or internal components loose.

3. Machine not properly mounted.

4. Faulty motor bearings.

1. Ensure sleeve is properly installed.

2. Inspect/replace damaged bolts/nuts and retighten

with thread-locking fluid.

3. Tighten mounting hardware.

4. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

Sanding stops

oscillating

Spindle drive belt is broken and re-

quires replacement.

Contact customer service at (800) 232-1195, M-F

8-5 CST for assistance. Repairs must be done by a

qualified technician.

TROUBLESHOOTING GUIDE

WARNING:

Stop using the tool immediately if any of the following problems occur. Repairs and

replacements should only be performed by an authorized technician. For any questions, please contact

our customer service at (800) 232-1195, M-F 8-5 CST or email us at techsupport@wenproducts.com.

16