WARNING:

Failure to comply to warnings and instructions may result in fire, electric shock, and/

or serious injury.

SAFETY INFORMATION

5

POWER TOOL USE & CARE

1. Avoid accidental start-ups. Make sure the power switch is in the OFF position before connecting to

power source, picking up or carrying the tool.

2. Check power tool for damaged parts. Check for misalignment of moving parts, jamming, breakage,

improper mounting, or any other conditions that may affect the tool’s operation. Do not use the power

tool if the switch does not turn ON/OFF. Any part that is damaged should be properly repaired or

replaced before use.

3. Do not force the tool to do a job for which it was not designed. Use the correct power tool and

accessories and follow the instructions for your application to prevent hazardous situations.

4. Remove adjustment tools. Always make sure all adjustment tools or wrenches are removed from

the tool before turning on the power tool. A key left attached to a rotating part of the power tool may

result in personal injury.

5. Keep guards in place and in working order before operating the tool.

6. Use dust extraction. If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection is highly

recommended to reduce dust-related hazards.

7. Never leave a running tool unattended. Do not leave the tool until it has come to a complete stop.

8. Disconnect the plug from the power source. ALWAYS remove the power cord plug from the electrical

outlet when making adjustments, changing parts, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

9. Maintain power tools properly. Safely store power tools out of the reach of children. Always keep tools

clean and in good working order. Follow instructions for lubricating and changing accessories.

CALIFORNIA PROPOSITION 65 WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities may

contain chemicals, including lead and wood dust, known to the State of California to cause cancer, birth

defects, or other reproductive harm. Wash hands after handling. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area with approved safety equipment such as

dust masks specially designed to filter out microscopic particles.

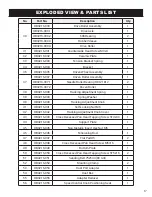

Summary of Contents for HB3216

Page 18: ...EXPLODED VIEW PARTS LIST 18 ...

Page 20: ......