English

ENG

ORIGINAL INSTRUCTIONS

6

have worn out from use other types of natural wear,

defects caused by failure to observe the instructions

for use and operation, or for applications other than

those for which this product is intended, abnormal

environmental factors, overloading, or unsuitable

maintenance or cleaning, faults caused by the use of

spare parts, accessories or replacements that are not

original Werku

®

parts, if the product has been totally

or partially disassembled, modified or repaired by

personnel other than that of the Technical Assistance

Service or minimum and irrelevant irregularities for

suitable use or operation. Repairs and replacements

will not extend or renew the validity period of this

warranty. The replaced parts will become the property

of Werku

®

. If the buyer sends the product to the

Technical Assistance Service, and it fails to comply

with the conditions of this warranty, all expenses

and transportation risks shall be paid by the buyer.

This warranty is only valid within the territory of the

European Union. The company responsible for the

compliance of this warranty is Werku Tools SA.

TECHNICAL ADVICE.

The technical department of Werku

®

is at your

disposal to resolve any questions you may have

regarding to its products. If you wish to contact our

team, send an e-mail to info@werku.com.

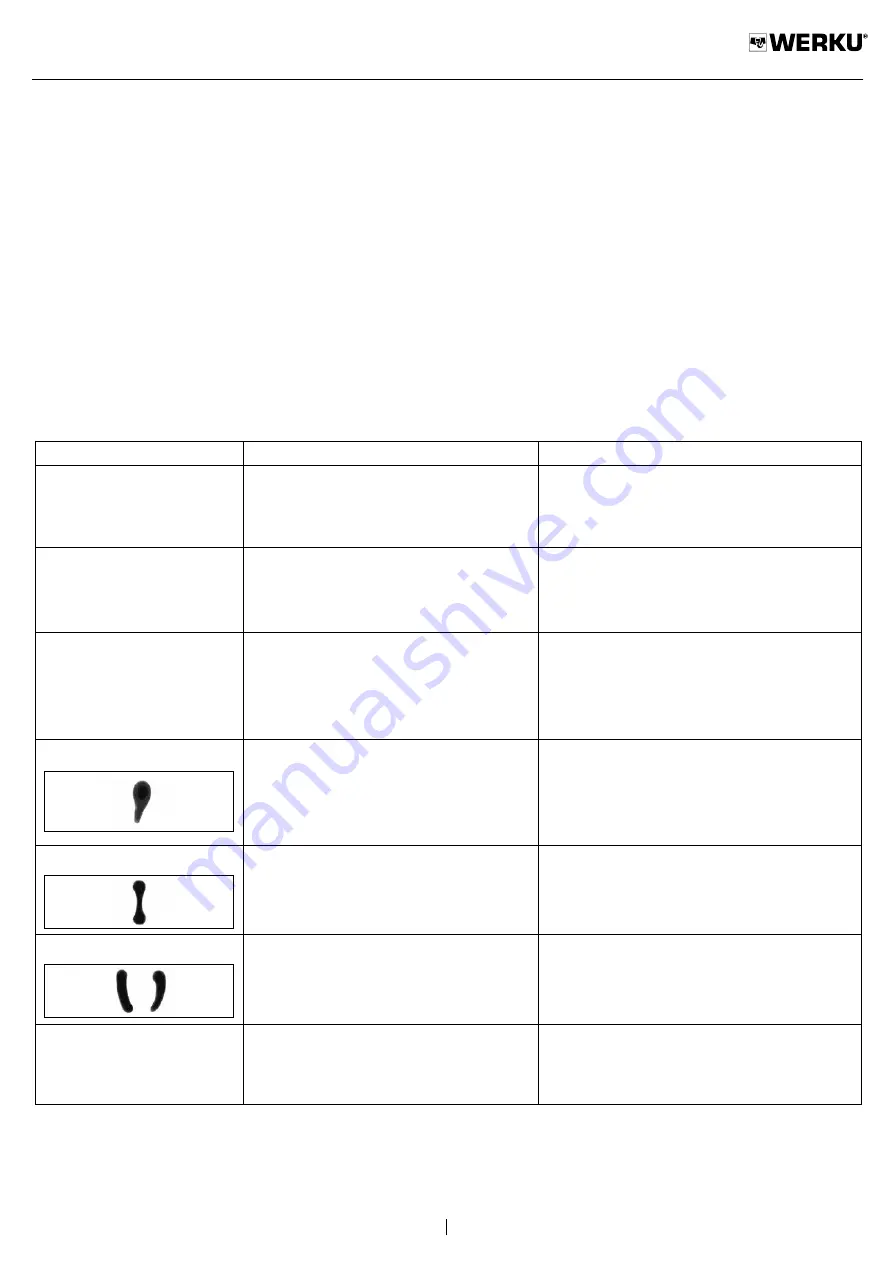

POSSIBLE PROBLEMS AND SOLUTIONS.

PROBLEM

CAUSE

SOLUTION

Spray size uneven due to

poor atomization.

Intermittent spray.

Overspray.

Badly formed spray pattern.

Lack of spray in the center.

Uneven fan shape.

Air or paint leak.

Too much paint entering air flow.

Insufficient air hitting paint flow.

Air is getting into the paint circuit.

Spray gun distance from work piece.

Technique.

Atomization too high.

Nozzle or air cap alignment.

Debris or dried paint blocking air cap.

Needle tip worn or damage.

Not enough paint entering air flow.

Too much air flow.

Air cap holes blocked on one side.

Needle tip and air cap worn or

damaged nozzle.

Sticking trigger or needle mechanism.

Loose or worn washers.

Decrease paint flow or reduce the nozzle

to the next size down.

Increase air flow with the air control.

Tighten the nozzle up with the multi size

spanner.

Check the paint pot is not empty.

Maintain a distance of 20 cm.

Make sure you are not flicking the gun on

the leading or trailing edge.

Reduce air flow with the air control.

Check that both are correctly seated.

Check and if necessary clean the air cap

and nozzle.

Replace needle assembly.

Increase paint flow or step up the nozzle to

the next size.

Reduce air flow with the air control.

Clean the air cap thoroughly.

Replace needle assembly.

Lubricate moving parts.

Check tightness, and if tight, replace and

lubricate washers.

Summary of Contents for WK501100

Page 37: ...37 WK501100 1 1 2 2 3 3 4 4 5 5 7 7 6 6 8 8...

Page 39: ...39 WK501100...