Anhang / Appendix / Annexes

21

0102

Updated: 16.08.2004

Page 2 of 2

This document is produced electronically and is legally binding, even without an original signature.

Cable glands with sealing inserts made from LSR and TPE-V are supplied with a connection thread sealing ring made from LSR.

Assembly

Select the cable gland depending on the bore/thread bore (thread type, length and diameter) in the casing and the external diameter of the cable or the

line. Unscrew the cable gland. Screw the double nipple into the bore in the casing, or counter it using a counter-nut if you are using a through bore.

Use the connection dimensions for through bores given in

Table 2.

Make sure that the connection thread – sealing ring is in the right position in the cable gland groove. The connection thread – sealing ring seals the

double nipple against casing wall. When the cable glands are located very close to each other, the socket spanner Ref. M 28 can be used to help

installation (see catalogue M 4.03 GKU pages 92 and 93 and catalogue 10.02. page 61).

Minimum wall thickness for installation in devices with thread bores : 5.0 mm (plastic); 3.0 mm (metal)

Minimum wall thickness for installation in devices with through bores : 2,0 mm (plastic); 1,0 mm (metal)

Shorten the cable / line to the right length to reach the connection point. Slide the pressure screw and the appropriate sealing insert over the cable

sheath (respect order and position). Insert the ends of the cable / line into the casing through the double nipple. Press the sealing insert into the double

nipple. Check that the sealing insert is in the right position. Then screw the pressure nut tightly onto the double nipple. For this operation you can also

use the M 28 socket spanner as a tool. The cable / line sheath is now sealed. The cable / line sheath should always be pushed inside the casing to make

sure that the cores are doubly insulated.

If the cable glands are properly fitted, it is possible to comply with IP 68 casing protection level according to EN 60529.

Indications for strain relief of the screwed cable gland

The cable gland with standard pressure screw is only suitable for permanently laid cables and lines. In this case the operator must provide for suitable

measures to supply strain relief.

Sealing rings mustn’t be cut out with a knife

The maximum acceptable number of cable glands depends on thread size and available space. The clearance and leakage distance to metallic

connection parts like clamps must be observed. Casing bores that are not in use must be sealed shut with an explosion-proof plug. Cable glands with

corresponding thread sizes must be closed off with a closed sealing insert or with a UNI E Ex e dummy sealing insert. Unused bores on multi sealing

inserts must be closed off with a stud.

Dismounting

Dismounting must be carried out in reverse order.

Maintenance

The cable glands must be included in the electrical equipment’s inspection and maintenance programme.

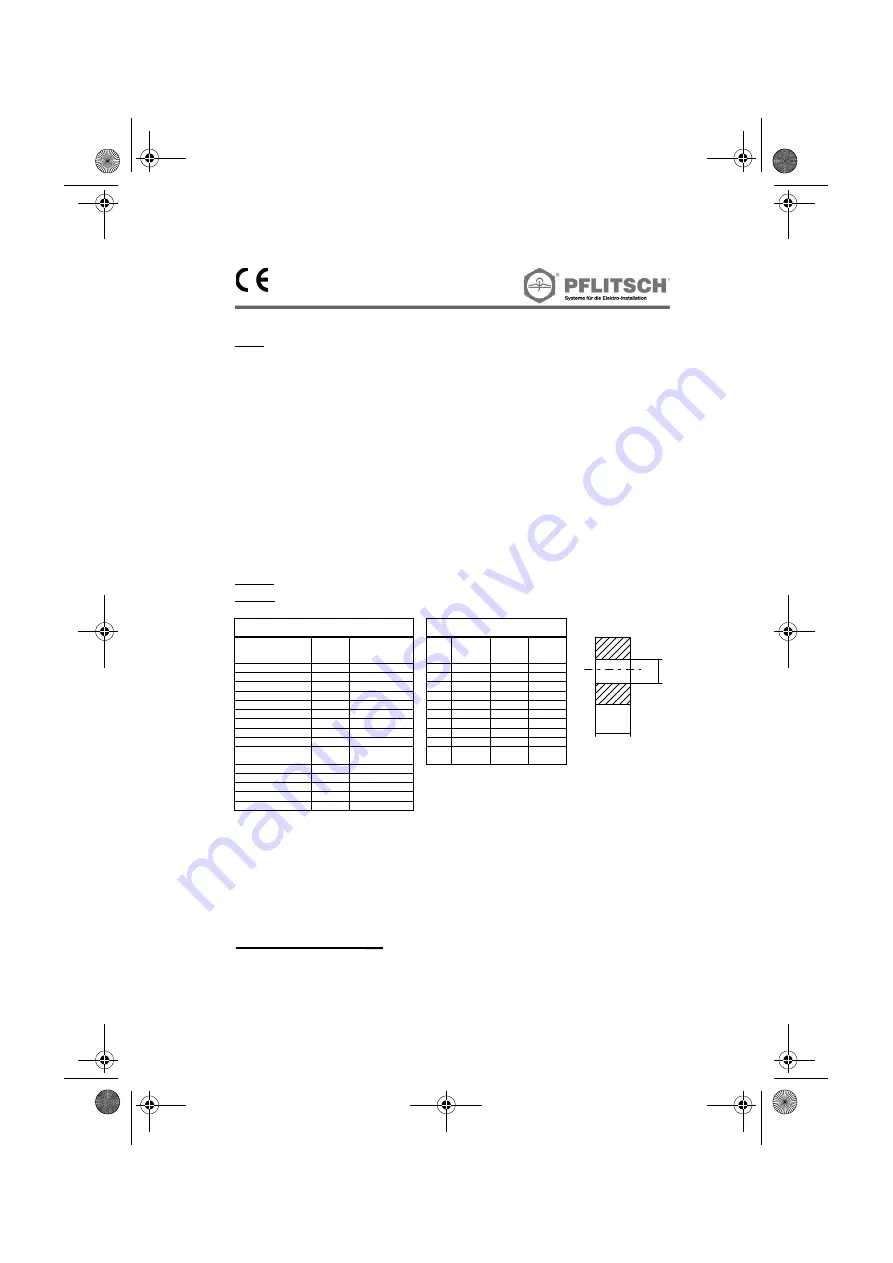

Table 1:

Table 2:

Colour codes for PVC sealing inserts for different

sealing ranges

Connection dimensions for through bores

Sealing range from -

to

( mm )

Colour

code

Colour

abbreviation

Pg d

[mm]

0/+ 0,3

metr. d

[mm]

0/+0,3

6,5 - 4,0

yellow

ge

7

12,5

M 10

10,0

8 - 5,0

grey

gu

9

15,5

M 12

12,0

9,5 - 6,5

black

sw

11

19

M 16

16,0

10,5 - 7,0

green

gr

13,5

20,5

M 20

20,0

13,0 - 9,0

red

rt

16

22,5

M 25

25,0

15,5 - 11,5

white

ws

21

28,5

M 32

32,0

18,0 - 14,0

blue

bl

29

37

M 40

40,0

20,5 - 17,0

brown

br

36

47

M 50

50,0

25,0 - 20,0

orange

or

42

54

M 63

63,0

28,0 - 24,0

light

yellow

hg

48 60 M

72 72,0

32,0 - 27,0

anthracite

an

34,0 - 29,0

light blue

hb

36,0 - 32,0

pink

rs

40,0 - 36,0

white

ws

44.0 - 39,0

white

ws

pp Benno Saßenbach

Stamp, date, signature

d

1,0 min

N. B.:

For sheet thicknesses of <1.5 mm, PY flat sealing rings must also

be used with metal cable glands in order to obtain a secure seal.

310_761_003_0305_A5.fm Seite 21 Mittwoch, 16. März 2005 4:35 16