Attaching the hardware to racks

StockSAVER manual - Software version 2.1

37

5.8.5

Configuring racks

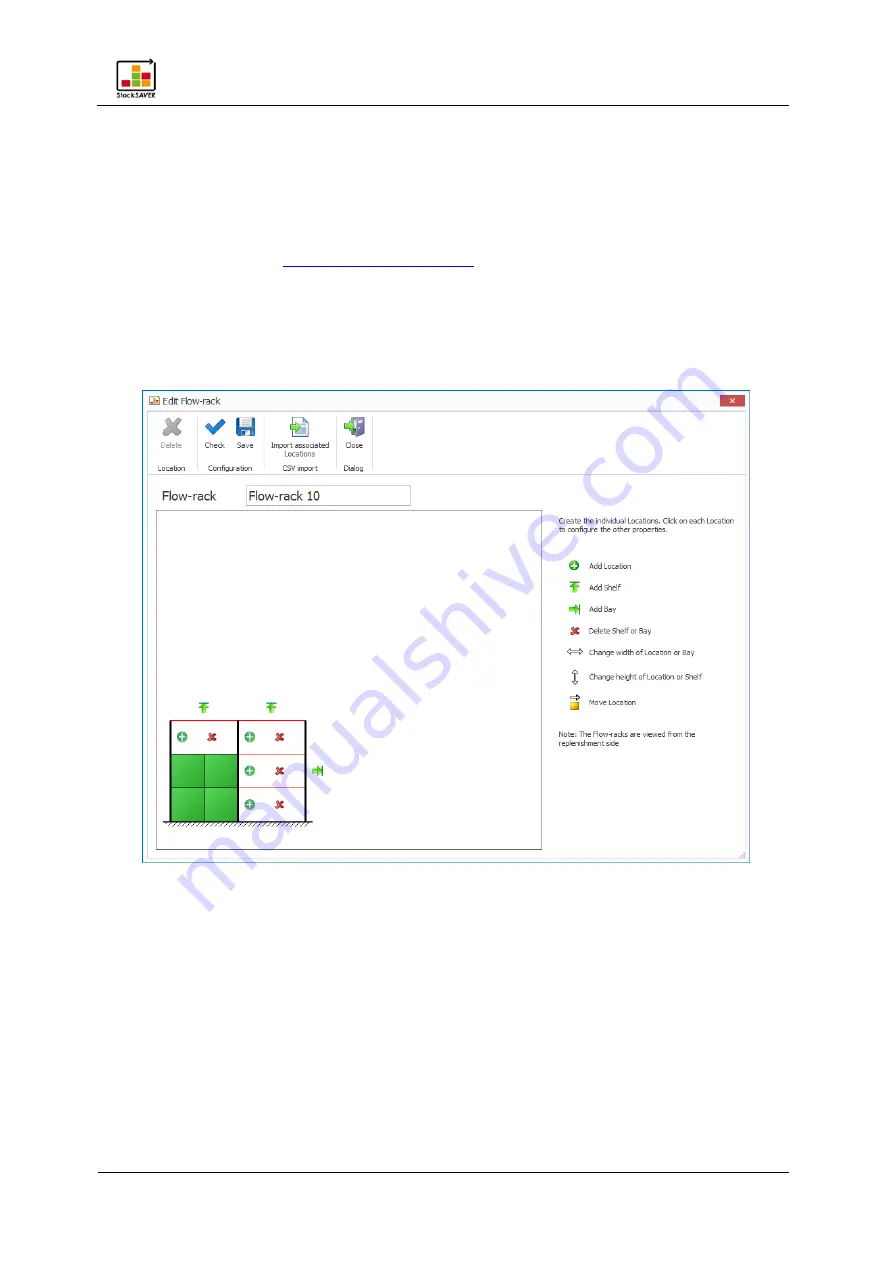

Map the racks in line with their current status in the software. Locations are represented by

green fields.

Note

−

A Part Number can be saved for every Location. To do so, the Material Master data must

first be created. See

−

Alternatively, Part Numbers can be assigned at a later date so you can continue with the

configuration. In this case, only the sensor statuses will be displayed in the Control Station.

−

Location transaction data is only continuously recorded once material has been assigned

to the Location.

1.

In the Edit Flow-rack dialog, click Add.

2.

Enter the rack name.

3.

Map the rack in line with its physical configuration using the configuration icons. Note that

the image view is from the Replenishment side.

4.

Click the green Location icon to enter a Location name, Part Number and stock limits for

every Location.

−

Location names must be unique. It is recommended to begin the Location name with

general information and become progressively more specific. Example of Location

name structure: Plant-Department-Aisle-Bay-Shelf-Location

−

An automatically assigned Location name is generated as default: Consecutive rack

number-Bay (alphabetical)-Shelf-Location.