4.2 Cam bio olio

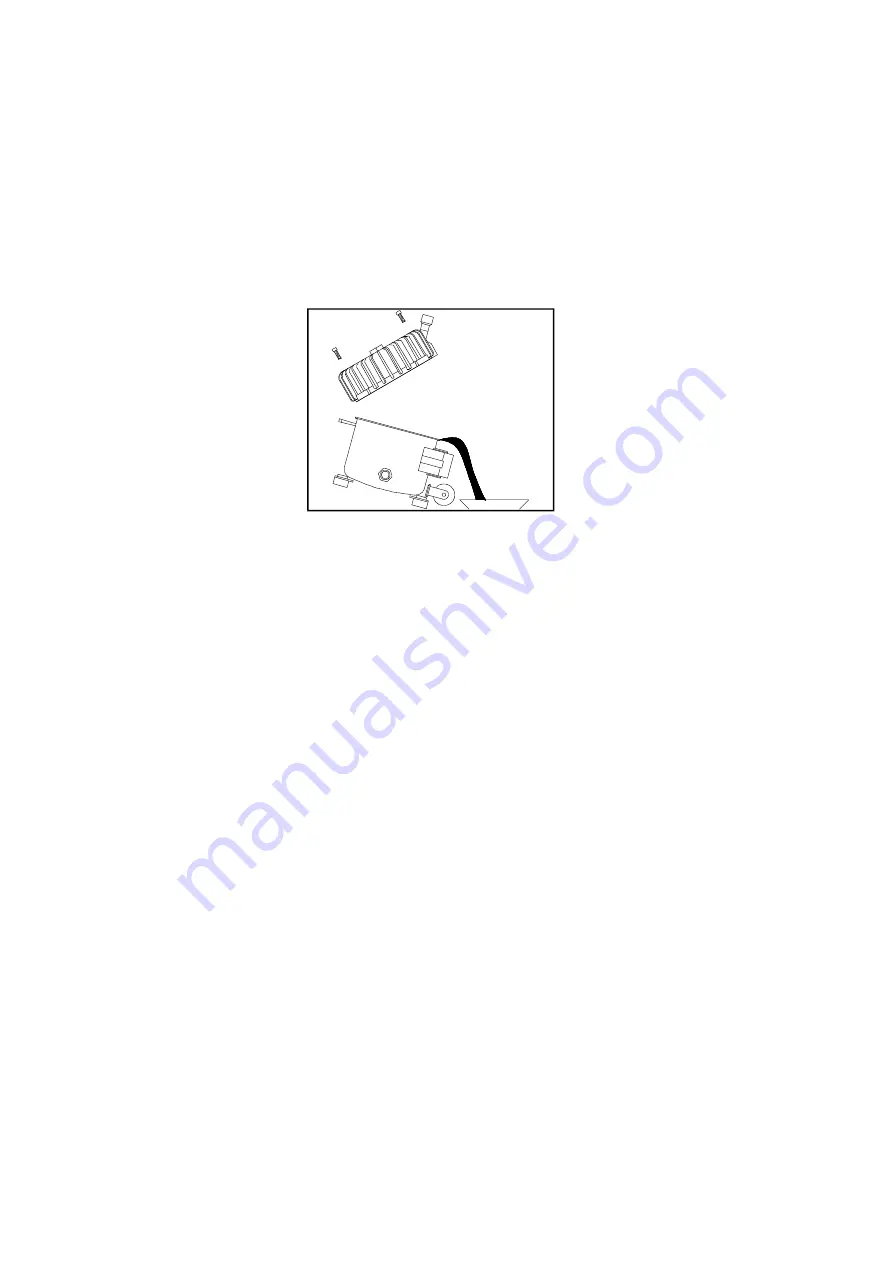

Pro ce de re come se gue fig.10:

1. Smon ta re il grup po mo to re dal ser ba toio

se necessario.

2. To glie re il co per chio alet ta to al len tan do

le 4 viti.

3. In cli na re il gruppo mo to re (

non ca po vol -

ger lo

) mante ne re il bloc co in ter no al suo

po sto con una mano.

4. Vuo ta re tut to l’o lio.

Nota ! L’o lio usa to deve es se -

re ri ci cla to in ac cor do alle

nor me am bien ta li in vi go re

Fig.10

5. Con trol la re l’O- ring del co per chio alet ta to.

6. Ri po si zio na re il co per chio alet ta to e con -

trol la re du ran te le ope ra zio ni che l’O- ring sia

po si zio na to cor ret ta men te per as si cu ra re

una chiu su ra a te nu ta al 100% tra la cas sa

ed il co per chio .

7. Av vi ta re le 4 viti del co per chio alettato.

8. Mon ta re il grup po mo to re sul ser ba toio.

I

IM POR TAN TE !

Usa re sem pre l’o lio “RO LOIL - SIN COM/32E

“ in quan to ogni al tro tipo di olio può cau -

sa re seri dan ni mec ca ni ci al com pres so re.

Di con se guen za la ga ran zia si ap pli ca solo

se si uti liz za l’ olio so pra in di ca to.

4.2 Oil replacement

Act as fol lows fig.10:

1. remove the mo tor unit from the tank, if

nec es sary.

2. re mo ve the fin ned co ver by loo sing the 4

screws.

3. tilt the mo tor unit to wards outlet side (

do

not turn it up side down

)and at the same

time keep the in ner unit in its seat with your

hand.

4. Empty all oil

Note! Waste oil must be re -

cy cled in con for mity with the

regu la tions in force

5. Check the O’ring of the fin ned cover

6. Pla ce the fin ned co ver in its seat again

and check that du ring the ope ra tions the

O’ring is pro perly pla ced in or der to en su re

a per fect seal betwe en hou sing and co ver.

7. Tigh ten the 4 screws of the fin ned cover

8. As semb le the mo tor unit on the tank

I

IM POR TANT!

Al ways use oil “ROLOIL – SIN COM/32E”

since any other type of oil can cause se -

vere me chani cal dam ages to the com -

pres sor.

Con se quently war ranty is va lid only if the

abo ve men tio ned oil is used.

16