3

/

22

REV. 01 2013

ITEM

PART NUMBER

DESCRIPTION

QTY

REMARK

1

YC1-3001800

Side cover

1

2

106B-2401001

Shell

1

3

202W-3018260

Cover

1

4

0202067

Screw M10X85 - GB/T70.1

1

5

0204005

Self-locking nut M10 - GB/T889.1

1

6

0511063

Grease brush

1

7

YC1-4299984

Grease cup

1

8

YC1-3000069

Spring

1

9

YC1-3002102

Wheel support

1

10

0202033

Screw M6X20 - GB/T70.1

4

11

YC1-3002099

Plastic foot

4

12

YC1-3006970

Bead lifting lever

1

13

0203029

Nut M8 - GB/T6170

2

14

0205008

Washer D.8 - GB/T97.1

2

15

YC1-3011970-1

Front panel

1

16

0201026

Screw M8X16 - GB/T5783

2

17

YC3-2412452-C

Pedal support

1

18

0201011

Screw M6X12 - GB/T5783

2

19

0205006

Washer D.6 - GB/T97.1

2

20

0202032

Screw M6X16 - GB/T70.1

5

21

0205007

Washer D.6 - GB/T96

9

BODY

TAV.1.1

ED.

04/13

Summary of Contents for TITANIUM BIKE

Page 2: ......

Page 9: ...REV 01 2013 7 24 2 3 DANGER WARNING SIGNS Fig 2 ...

Page 14: ...REV 01 2013 12 24 ...

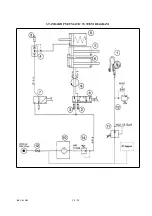

Page 26: ...REV 01 2013 24 24 STANDARD PNEUMATIC SYSTEM DIAGRAM ...

Page 27: ......

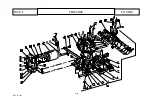

Page 28: ... 2 22 REV 01 2013 BODY TAV 1 1 ED 04 13 ...

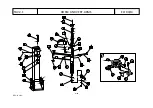

Page 30: ... 4 22 REV 01 2013 HORIZ AND VERT ARMS TAV 2 1 ED 04 13 ...

Page 33: ... 7 22 REV 01 2013 PEDAL BOX TAV 3 1 ED 04 13 ...

Page 37: ... 11 22 REV 01 2013 BEAD BREAKER TAV 4 1 ED 04 13 ...

Page 40: ... 14 22 REV 01 2013 SELFͲCENTERING TURNTABLE TAV 5 1 ED 04 13 ...

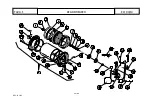

Page 44: ... 18 22 REV 01 2013 3 MOTOR REDUCTION GEAR GROUP TAV 6 0 ED 04 13 ...

Page 47: ... 21 22 REV 01 2013 AIR LUBRICATOR GROUP TAV 8 1 ED 04 13 ...