10

EN

The on/off switch is fitted with a brake function which

stops your chuck immediately when you quickly release

the switch.

It is also a variable speed switch that delivers higher

speed and torque with increased trigger pressure. Speed

is controlled by the amount of switch trigger depression.

WARNING:

Do not operate for long periods

at low speed because excess heat will be

produced internally. When overload occurs, release

the on/off switch immediately to avoid the motor

overheating.

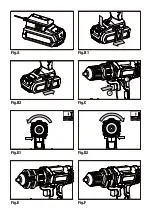

2. SWITCH LOCK (SEE FIG. C)

The switch trigger can be locked in the OFF position.

This helps to reduce the possibility of accidental starting

when not in use. To lock the switch trigger, place the

rotation control in the center position.

3. REVERSIBLE (SEE FIG. D1, D2)

For drilling and screw driving use forward rotation

marked “

” (lever is moved to the left of the drill)

(D1). Only use reverse rotation marked “

” (lever is

moved to the right of the drill) (D2) to remove screws or

release a jammed drill bit.

WARNING: Never change the direction of

rotation when the chuck is rotating, wait until

it has stopped!

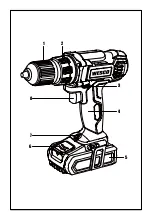

4. CHUCK ADJUSTMENT (SEE FIG. E)

To open the chuck jaws rotate the front section of the

chuck. Insert the drill bit between the chuck jaws and

rotate the front section in the opposite direction. Ensure

the drill bit is in the center of the chuck jaws. Finally, firmly

rotate the front chuck section in the opposite directions.

Your drill bit is now clamped in the chuck.

5. TORQUE ADJUSTMENT (SEE FIG. F)

(Screw driving force of your drill driver)

The torque is adjusted by rotating the torque adjustment

ring. The torque is greater when the torque adjustment

ring is set on a higher setting. The torque is less when the

torque adjustment ring is set on a lower setting.

Make the setting as follows:

1 - 4 for driving small screws

5 - 9 for driving screws into soft material

10 - 14 for driving screws into soft and hard material

15 - 19 for driving screws into hard wood

20 - 21 for driving larger screws

for heavy drilling

6. AUTOMATIC SPINDLE LOCK

The automatic spindle lock allows you to use it as a

regular screwdriver. You can give an extra twist to firmly

tighten a screw, loosen a very tight screw or continue

working when the battery energy has expired. For

manual screwdriver purposes, the chuck is automatically

locked when the tool is off.

7. USING THE LED LIGHT

To turn on the LED light simply press the on/off switch.

When you release the on/off switch, the light will be off.

LED lighting increases visibility-great for dark or

enclosed area.

8. DRILLING

When drilling into a hard smooth surface, use a center

punch to mark the desired hole location. This will

prevent the drill bit from slipping off center as the hole

is started.

Hold the tool firmly and place the tip of the bit at the

point to be drilled.

Depress the switch trigger to start the tool.

Move the drill bit into the workpiece, applying only

enough pressure to keep the bit cutting. Do not force or

apply side pressure to elongate a hole.

WARNING: Tungsten carbide drill bits should

always be used for concrete and masonry.

When drilling in metal, only use HSS drill bits in

good condition. Always use a magnetic bit holder

when using short screwdriver bits. When screw-

driving, apply a small quantity of liquid soap or

similar to the screw threads to ease insertion.

9. DISPOSAL OF AN EXHAUSTED BATTERY PACK

To preserve natural resources, please recycle or

dispose of the battery pack properly. This battery

pack contains Lithium batteries. Consult your

local waste authority for information regarding available

recycling and/or disposal options. Discharge your

battery pack by operating your drill, then remove the

battery pack from the drill housing and cover the battery

pack connections with heavy-duty adhesive tape to

prevent short circuit and energy discharge. Do not

attempt to open or remove any of the components.

10. OVERLOAD PROTECTION

When overloaded, the motor comes to a stop. Relieve

the load on the machine immediately and allow cooling

for approx. 30 seconds at the highest no-load speed.

11. TEMPERATURE DEPENDENT OVERLOAD PROTECTION

When using as intended for the power tool cannot be