M6 x 63mm Screw (43)

M

M8 x 63mm Bolt (22)

M8 x 70mm Bolt (11)

M

M8 x 67mm Bolt (72)

M8 x 115mm Bolt (64)

M

M10 x 97mm Bolt (16)

M10 x 87mm Bolt (25)

M

45mm Square Inner Cap (44)

50mm Square Inner Cap (27)

50mm Square Outer Cap (51)

M8 x 63mm Carriage Bolt (1)

M8 x 67mm CarriageBolt (14)

M10 x 198mm Bolt (59)

M10 x 60mm Bolt (7)

Summary of Contents for Gym 1000

Page 20: ...20 NOTES ...

Page 21: ...21 NOTES ...

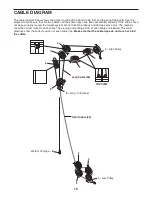

Page 26: ... V Pulley 6 Not shown to scale 90mm Pulley 15 Not shown to scale ...