18

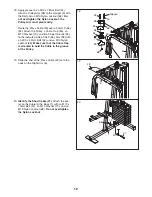

The cable diagram below shows the proper routing of the Short Cable (47), the Low Cable (48), the Press

Cable (49), and the High Cable (50). Use the diagrams to make sure that the cables have been assembled cor-

rectly. If the cables have not been correctly routed, the weight system will not function properly and damage may

occur. The numbers show the correct route for each cable.

High Cable (50)

CABLE DIAGRAM

4

4

1

2

1

2

5

5

5

4

3

2

1

Press Cable (49)

Low Cable (48)

Short Cable (47)

3

3

1

2

3

Summary of Contents for Gym 650

Page 20: ...20 NOTES ...