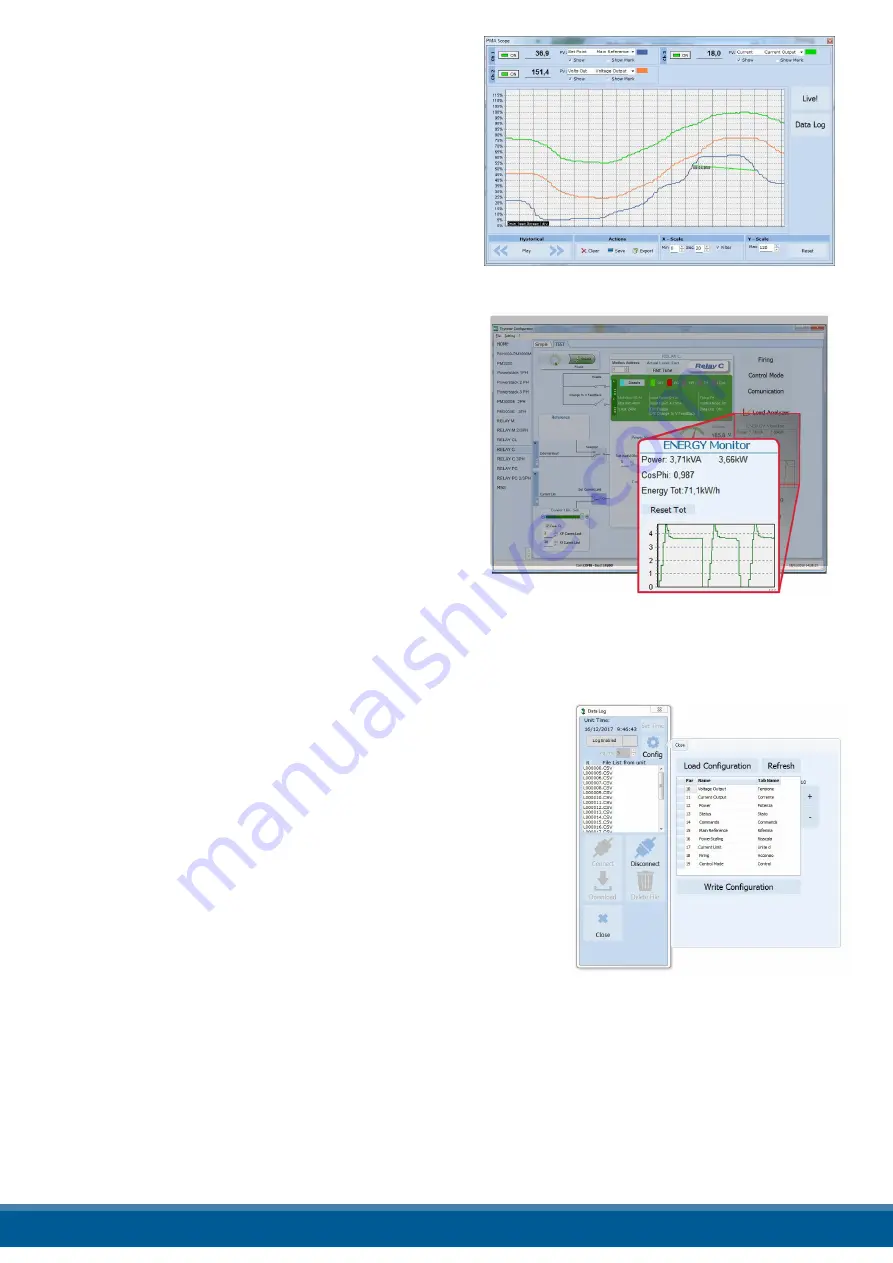

13.5.7 To view data on the scope:

1) Click

Test,

if not already on the test view

2) Click

Online

3) Click

Load Analyzer

4) For each of up to three channels (Ch 1 to Ch 3):

- With

PV1

choose the value to monitor

- Select Show

- Click the colour swatch to change the colour

- Click the button to turn the channel on.

13.5.8 To reset the power totals:

1) Click

Test,

if not already on the test view

2) Click

Online

3) Click

Reset Totals

4) Click

Yes

13.5.9 Setting Up and Using Data Logging

To set up data logging:

1) Click

Test,

if not already on the test view

2) Click

Online

3) Click

Load Analyzer

4) On the

Load Analyzer

view click

Data Log

5) In the

Data Log

window ensure the slider is set to

Log Enabled

6) Click

Set Time

7) If necessary Set the date and time and close the date/time window

8) Set

Log Time

to the number of seconds between records

9) Click

Connect

10) Click

Config

11) Click

Load Configuration

to view the current list of logged parameters

12) For up to ten parameters to log:

-Click

+

to add a parameter to the list

-In a row in the list either: Type a parameter’s Modbus address in the

Par

field

OR

-Select the parameter from the drop down list in the

Name

field

13) Click

Write Configuration

to send the parameter list to the controller

14) Click

Close

15) Click

Disconnect

16) Close the

Data Log

window

www.west-cs.co.uk

42