Section BXM‐05V‐20A

030‐101643 Rev. B

R

3

1205IARB

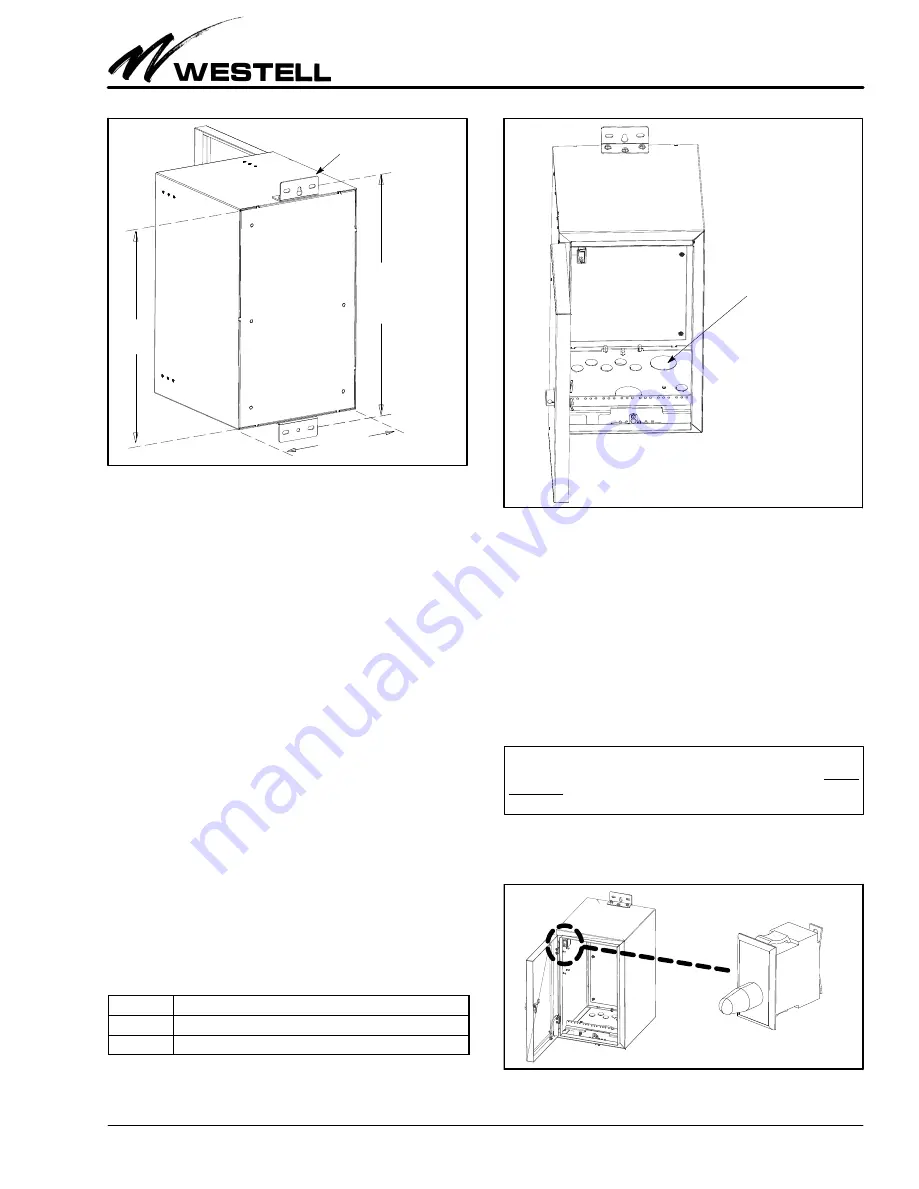

Figure 5.

Rear Isometric View

Mounting Bracket

25.18"

14" wide

23"

high

(between

mounting

holes)

tional security is available when a padlock is inserted through

the two holes in the protruding cylindrical lock wall: a padlock

hasp installed through the hole denies door tool access (tool

cannot reach the hex screw).

2.1.3

Front Door

A full‐size locking door provides maximum technician and

equipment access to the interior of the cabinet and also helps

protect the cabinet from tampering and vandalism. When the

cabinet is mounted and the door is open, the distance from the

back of the mounting brackets to the outer edge of the door's

lock flange is 29.11” (as shown in Figure 4). The door opens to

approximately 120 degrees. In the closed position, a gasket

installed around the inside perimeter of the door abuts the

front cabinet flange. When the door lock is tightened, the cab

inet's door flanges and gasket provide a weather‐tight seal to

protect all equipment installed inside the cabinet. The door

switch/sensor is described in Paragraph 2.2.1.

2.1.4

Mounting Brackets

Two mounting brackets are provided at the back wall of the

Boxer cabinet, one at the top and one at the bottom. Each

bracket has three mounting holes or slots. The center hole of

the top bracket is a keyhole, for easy one‐person, cabin

et‐self‐leveling mounting. Use mounting fasteners with a

diameter of up to

3

/

8

”). The vertical distance between the top

and bottom mounting bracket hole centers is 25.18” (see

Figure 5).

Quantity

Description

2

2.5” knock‐out for 2” conduit

6

1.125” knock‐out, for 3/4” conduit

Table 1. Knock‐out Sizes and Quantities

Figure 6.

Front View Showing Knock‐out Locations

Knock-outs on Floor

(2 large and 6 small

knock-outs)

2.1.5

Bottom Floor Knock‐outs

Multiple knock‐outs are provided on the floor of the cabinet.

The knock‐out sizes and quantities are shown in Table 1 and

Figure 15. Do not remove a knock‐out unless it is absolutely

necessary to do so for cable ingress and egress, and use either

tight‐fitting rubber grommets or liquid‐tight fittings, or other

proper and approved knock‐out hole sealants, to assure the

best internal air quality and weather‐resistance. Always use

proper and company‐approved tools to remove knock‐outs.

There are four, small, 0.300” diameter knock‐outs in the floor

of the Boxer cabinet where an optional battery box attaches to

the cabinet (hole patterns of both units match).

‐ KNOCK‐OUT REMOVAL NOTE ‐

Always remove knock‐outs where holes are desired before

mounting the cabinet or the optional battery box, regardless of

the type of knock‐out and the order of the mounting steps.

Figure 7.

Door Switch Location

Door Switch