Section DSA-WM2-140-202

030-101674 Rev. A

R

4

0803I2RA

Enclosure

Back Plate

Channel of 19" or

23" Equipment Rack

DSAWM-214

Enclosure

Enclosure can be mounted in racks with either 1" or 1.75" rack unit spacing.

Kit # 080-500455 is designed to mount 214 to rack. First mount kit to mounting , then mount

enclosure to kit mounting plate.

Figure 3. DSAWM-214 Enclosure Mounting Diagram

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍ

È

È

È

È

È

È

È

È

È

ÈÈÈÈÈÈÈÈ

ÈÈÈÈÈÈÈÈ

ÈÈÈÈÈÈÈÈ

ÈÈÈÈÈÈÈÈ

DSAWM-214

Enclosure

Rack Mounting (Optional)

Wall Mounting

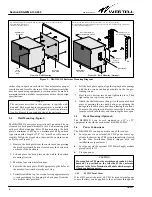

The back mounting plate is designed with two top keyhole slots to facilitate mounting.

First install back plate to wall,

then mount enclosure to plate.

Knock-Out Hole for

Optional Cable Access

Figure 3a.

Figure 3b.

TB1

Wire

Access

Hole

Cable Access

Holes to

Back Panel

Mounting Ear

inches of open space on each side of the enclosure for proper

ventilation and for cable clearance. If the enclosure is installed

near heat-producing equipment, provisions must be made to

maintain installed module temperatures within their design

specifications.

- NOTE -

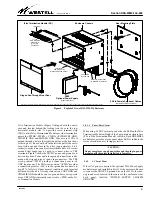

The enclosure described in this practice is typically wall-

mounted. Rack mounting in equipment racks is available with

rack-mount kits (Figure 3). See Table 5 for ordering informa-

tion. See Figure 4 for an exploded view of the enclosure.

3.2

Wall Mounting (Typical)

The DSAWM-214 enclosure is typically wall-mounted. The en-

closure has a back panel which serves as a wall-mounting plate

with predrilled mounting holes. When mounting the back

plate, a minimum of #12 up to a maximum of #16 pan-head

type screws with a length of 7/8" to 1" must be used to ensure

stability. Follow the steps below to mount the enclosure on a

wall (also see Figure 3).

1. Remove the back plate from the enclosure by depressing

the black metal push buttons located near the bottom on

each side of the enclosure.

2. Lift and place the back plate on the wall in the desired

mounting location.

3. Mark the four screw hole locations.

4. Set aside the back plate. Drill appropriate pilot holes at

the marked locations before the next step.

5. Partially install the top two screws, leaving approximately

¼-inch protruding for hanging the back panel from the

two keyhole slots provided.

6. Lift the back plate again, align the top keyhole openings

with the two screws and hang back plate on the two pro-

truding screws.

7. Start the two bottom screws and tighten in place. Then

tighten the two top screws in place.

8. Attach the shelf enclosure (hang it) to the mounted back

plate by pressing the two push buttons, positioning the

unit against the back plate, and then releasing the buttons.

To access the plug-in module slots, insert the key in the

front door lock, turn the key and then swing the door open.

3.3

Rack Mounting (Optional)

The DSAWM-214 can be rack mounted in a 19" or 23"

equipment rack with the rack-mount kit # 080-500455.

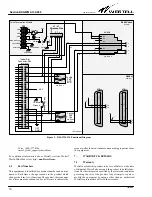

3.4

Power Connections

The DSAWM-214 can be powered in one of three ways:

D

Local power via an external -48 VDC power source ap-

plied to the barrier-type TB1 screw terminal strip (located

on the

Telco Termination Module

shipped with and

installed in every enclosure)

D

Local power via the optional 2555 Power Supply module

placed into Slot 15

D

Via span power

- CAUTION -

Power applied to TB1 must be wired through conduit. A hole

knock-out is provided on the left side of the enclosure

adjacent to the Telco Termination Module which accepts a

½-inch conduit connector.

3.4.1

-48 VDC Local Power

If local DC power is desired, -48 VDC from an external power

source (battery) can be applied to the enclosure through the