Section DSA-WM2-140-202

030-101674 Rev. A

R

2

0803I2RA

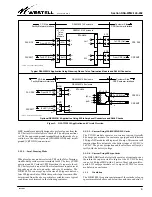

the unit or via the XMT and RCV 25-pair Amphenol-type

male connectors at the rear of the enclosure

D

Customer side connections made via either the two

RJ48H D-connectors or the modular RJ48C jacks, all lo-

cated on the lower front of the enclosure

D

Removable, tinted, front door allows visual monitoring of

module LEDs

D

Keyed front door locking mechanism provides security

D

Static wrist-strap jack at front of unit for Electrostatic Dis-

charge (ESD) protection

D

Totally grounded enclosure with chassis ground lug at bot-

tom front of enclosure

D

Top and bottom heat ventilation and convection holes

D

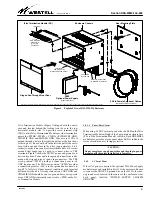

Circuit Assignment Card facilitates easy module identifi-

cation and assignment

D

Strategically-placed cable tie-downs for efficient, neat,

cable management

D

Enclosure chassis and interior frame all heavy gauge steel

for strength, durability, and longevity

Telco Termination Module (Local DC/GND)

D

Terminal Block (TB1) for local DC power and ground con-

nections

D

S1 Slide Switch for THRU" or OPEN" for selecting ei-

ther an open or through shield ground from TB1

D

Fourteen 6-pin wirewrap connectors, J1 through J14 (one

for each slot), at front of Telco Termination Module pro-

vide termination points for CO-side cable wires when

using 200-type cards

D

Front panel ALARM LED lights when fuse is blown

D

Front panel fuse rated at 2 amps

Optional AC Power Supply

D

Accepts optional local AC powering (Westell model 2555)

in the 15th slot

3.

INSTALLATION

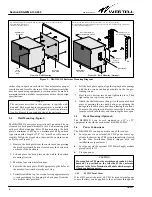

Installation consists of examining some pre-mounting con-

cerns, physically mounting the enclosure (back plate) on a wall,

making the necessary electrical, power, ground, and signal

cable connections, and installing the DNI or HDSL modules in

the enclosure. The following paragraphs provide detailed in-

structions for performing these procedures.

3.1

Pre-Mounting Considerations

Before installing the enclosure, visually inspect the unit for

damages, follow proper safety and ESD precautions and proce-

dures, evaluate and determine the proper mounting

application, installation personnel, and installation environ-

ment (mechanical, thermal, electrical), and gather the

required mounting tools, mounting hardware, and test equip-

ment.

The DSAWM-214 enclosure should be installed by authorized

trained personnel only. In accordance with UL 1950, this

mounting enclosure is suitable for mounting on concrete or

other noncombustible surfaces only. It is also recommended

that adequate horizontal and vertical space be left between

multiple installations to allow for proper cable access and ven-

tilation. The distance from the cable entry point should be

consistent with local installation practices.

- NOTE -

Visually inspect the equipment for damage at the time of delivery:

if damaged in transit, immediately report the damage to the

transportation company and Westell.

- CAUTION -

- Never install telephone wiring and/or telephone equipment

during a lightning storm.

- Never install telephone jacks in wet locations unless the

jack is specially designed for wet locations.

- Never touch uninsulated telephone wires or terminals

unless the telephone line has been disconnected at the

network interface.

- Always use caution when installing or modifying telephone

equipment.

- All wiring should be done by a certified technician using

only approved telephone wire.

3.1.1

Considering Safety

When using and installing telephone/telecommunications

equipment, basic safety instructions should always be followed

to reduce risk of fire, electric shock, and injury to people and

equipment, including the following:

Important Safety Instructions (Please Save)

A.

Read and understand all instructions.

B.

Follow all warnings and instructions marked on product.

C.

Do not place this product on an unstable cart, stand, table or other

unstable surfaces: the product may fall, causing serious damage to

product.

D.

Slots and openings in the product are provided for ventilation. To

protect it from overheating, these openings must not be blocked or

covered. This product should never be placed near or over a radia-

tor or heat register. This product should not be placed in a built-in

installation unless proper ventilation is provided.

E.

This product should be operated only from the type of power

source indicated on the marking label.

F.

Never push objects of any kind into this product through product

slots as they may touch dangerous voltage points or short out parts

that could result in the risk of fire or electrical shock. Never spill liq-

uid of any kind on the product.

G.

Perform ground connections prior to power connections.

H.

Follow and use proper Electrostatic Discharge (ESD) precautions

and procedures.

3.1.2

DC Powering & Heat Release Considerations

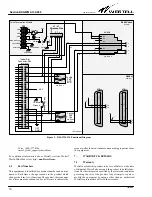

T1 NIU modules and HDSL HRU modules in the DSAWM-214

enclosure can be either line/span powered remotely from a Cen-

tral Office (CO) or locally powered via either a

Telco Termination

Module

(and a -48 VDC power source) or from a plug-in AC

power supply.

3.1.2.1

Line Powering Mode

When these modules are utilized in a line power mode, the -48

V battery should not be connected to the enclosure. The HDSL