Section DSA-WM2-140-202

030-101674 Rev. A

R

6

0803I2RA

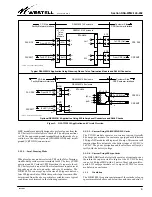

Figure 5. Close-Up of Connector Types

Pin 4 (R)

Typical RJ48C Jack

Pin 1 (R1)

Pin 2 (T1)

Pin 5 (T)

1

2

3

4

5

6

7

8

Front

Rear

Amphenol-type 50-pin Male

RCV and XMT Connector

Pin 50

Pin 26

Pin 25

Pin 1

RJ48H

J1 Through J14

J15

Customer Side Connections

CO Side Connections

Pin 50

Pin 26

Pin 25

Pin 1

Customer Side Connections

(Female)

Cable Output Direction

Cable Output Direction

J16

- GROUNDING CAUTION -

Always follow local safety precautions and standard operat-

ing procedures for grounding the equipment when instal-

ling, upgrading, repairing or maintaining equipment. Any

instructions or information contained herein is subordinate

to local codes, operating procedures or practices.

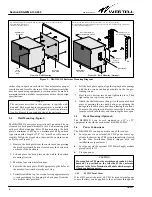

3.5

Grounding

When properly installed, the DSAWM-214 enclosure is a total-

ly grounded system at the installation site. The enclosure

provides points for chassis/frame, circuit ground, cable shield

ground, and a static ground.

3.5.1

Chassis/Frame Ground Connections

Chassis ground prevents voltage from building up on the sur-

face of the equipment. The enclosure chassis must be

connected to an earth ground at all times in order to properly

ground the enclosure’s metal framework and all module front

panels. A separate ground conductor/wire is recommended for

chassis/frame ground (separate from the circuit ground). One

end of this conductor/wire must be connected to the enclo-

sure’s external ground lug (located near the front of the unit

under the module housing, as shown in Figure 6) and the other

end must be wired directly into the multi-ground neutral of the

building ground. A shorting bar is provided (but not factory-

installed) for optional installation between the CHASSIS

GND and CKT GND terminals on TB1, for applications re-

quiring chassis ground to be connected to circuit ground.

3.5.2

Circuit Ground Connections for Local DC Power

Circuit ground provides a lightning return path and is recom-

mended to be directly and separately connected to earth

ground regardless of the power source or type (local or span).

Circuit ground must be connected to position CKT GND of

TB1 on the

Telco Termination Module

for proper operation of

the secondary lightning protection and for proper operation of

the modules plugged into the enclosure. This ground connec-

tion should be made via a separate conductor to the

multi-ground neutral of the building ground.

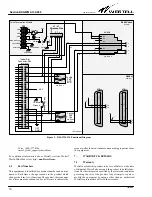

Position

Label

Function

1

SHIELD

GND

Provides a ground connection point to the

incoming shield wires connected in pin 1 of the

Wirewrap Interface Card.

2

CHASSIS

GND

Provides a ground connection point for the metal

enclosure and DNI front panels.

3

+PWRB/

CKT GND

Provides a connection point for battery return and

connects to pin 17 of all slots. This terminal must

be connected to EARTH to maintain

lightning/overvoltage protection.

4

+PWRA

Provides a connection point for battery return and

connects to pin 17 of all slots. For back-up power

supply.

5

-PWRA

Provides connection point for -48V battery for

back-up power supply.

6

-PWRB

Provides connection point for -48V battery.

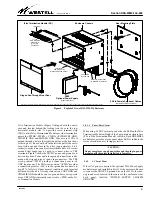

Table 1. TB1 Connections

3.5.3

Local AC Powering Ground Connections

When local AC is used with the 2555 Power Supply, the GRN/

YEL ground wire on the 2555 may be connected to the

enclosure’s chassis ground screw labelled POWER SUPPLY

CHASSIS GROUND" located in the center of the enclosure’s

rear back panel. This gives the customer an alternate means of

utilizing the outlet ground through the power supply cord.