_____________________________________________________________________________________

4

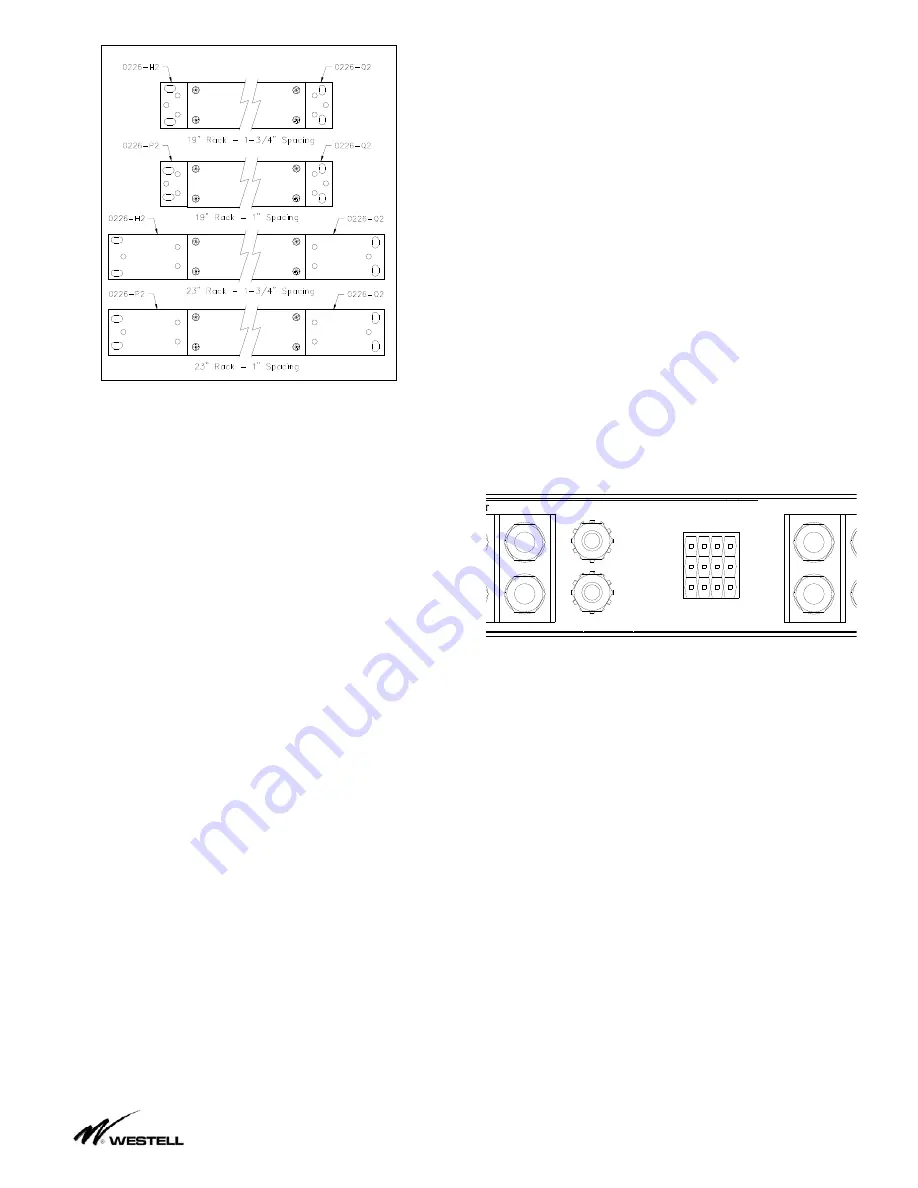

Mounting Options

Figure 4.2.1

4.3.

Mount the fuse panel in the required

position on the equipment rack using #12-24

thread forming rack mounting screws with

external tooth lock washers that are provided

with the panel.

WARNING:

For safety reasons all wiring

should be done with power source removed.

4.4.

Remove the distribution fuse or breaker

feeding the input cables that are to be

connected to the new panel. Note this panel

can handle a maximum of 125 Amps per

input. Please do not fuse/breaker the input

cables at more than 150 Amps each. Using

input cables specified by the Job Engineer,

hook up the battery input cables to the input

blocks on the back of the fuse panel (“BAT

IN” & “RTN IN” for each input). Each input

terminal uses a two hole compression lug

(1/4” on 5/8” centers, torque to 3 ft-lbs). See

Figure 4.5.1.

4.5.

Battery outputs (“BAT OUT” & “RTN

OUT”) for each fuse position are also

accessible through ¼” stud terminal blocks at

the rear of the panel. Each fuse position is

numbered on the face plate and that circuits

output is available at the back of the panel

with the same number. Note that each return

is isolated from the chassis frame and

isolated from all other returns. See Figure

3.1.1.

Note:

For this high current panel, a two hole

lug must be used on all stud blocks (input and

output, battery and return) for the fuse panel

to function properly.

4.6.

Each fuse position has a common (C),

normally open (NO) and normally closed (NC)

set of contacts for extending alarms. (See

figure 4.6.1 for the location and layout of the

alarm relay contacts). Wire wrap the alarm

connections as per your alarm systems

requirements. For example; to achieve a

“ground alarm extension”, connect a ground

supply to the common (C) contact and

connect the alarm signal wire to the normally

open (NO) contact. In an alarm state a

“ground” will be sent out from the panel.

COM

NC

NO

1

2

3

4

CHASSIS

GND

BAT IN

BAT OUT

ALARMS

Figure 4.6.1

Note:

To protect the alarm wiring and

circuitry, the current will be limited through the

alarm contacts to 1A by a self-resetting over

current device (1Amp P.T.C.). See the

attached schematic (drawing 1009-10).

4.7

Chassis Grounding; for safety reasons,

the chassis should be electrically connected

to the rack ground. From step 4.3, the panel

should already be bonded to the rack via the

#12-24 thread forming rack screws and

outside tooth lock washers used to pierce the

paint (this hardware must be used to pierce

paint on the panel and the rack). In addition

to grounding via the mounting brackets, it is

recommended that the chassis be further

grounded using a separate ground bonding