19

Westendorf Manufacturing Co., Inc.

WESTENDORFMFG RR315270

MAX Loaders

SECTION 4: OPERATION

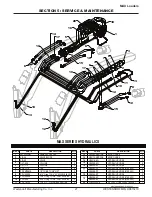

LOADER DAMAGE.

To prevent damage

to loader and/or

tractor:

• Stop

loader

gradually

when lowering

heavy loads.

•

NEVER

drop a load

and “catch” hydraulically.

• Hydraulically stopping a load after it has gained downward

momentum can damage the loader and/or tractor.

Handle all raised loads with caution. Keep eyes on load

while raising or lowering to be sure the load does not fall

out of the back of the bucket.

NEVER

travel with a

raised load. Raise the

load when approaching

equipment. Keep loads

close to work area to

minimize travel time.

Keep loading area level

to prevent rollover. Do not raise load higher than required

while dumping.

Dump the load by moving the control level

outward.

After dumping the load, back away and

move the single lever control forward and

inward to lower and rollback the bucket.

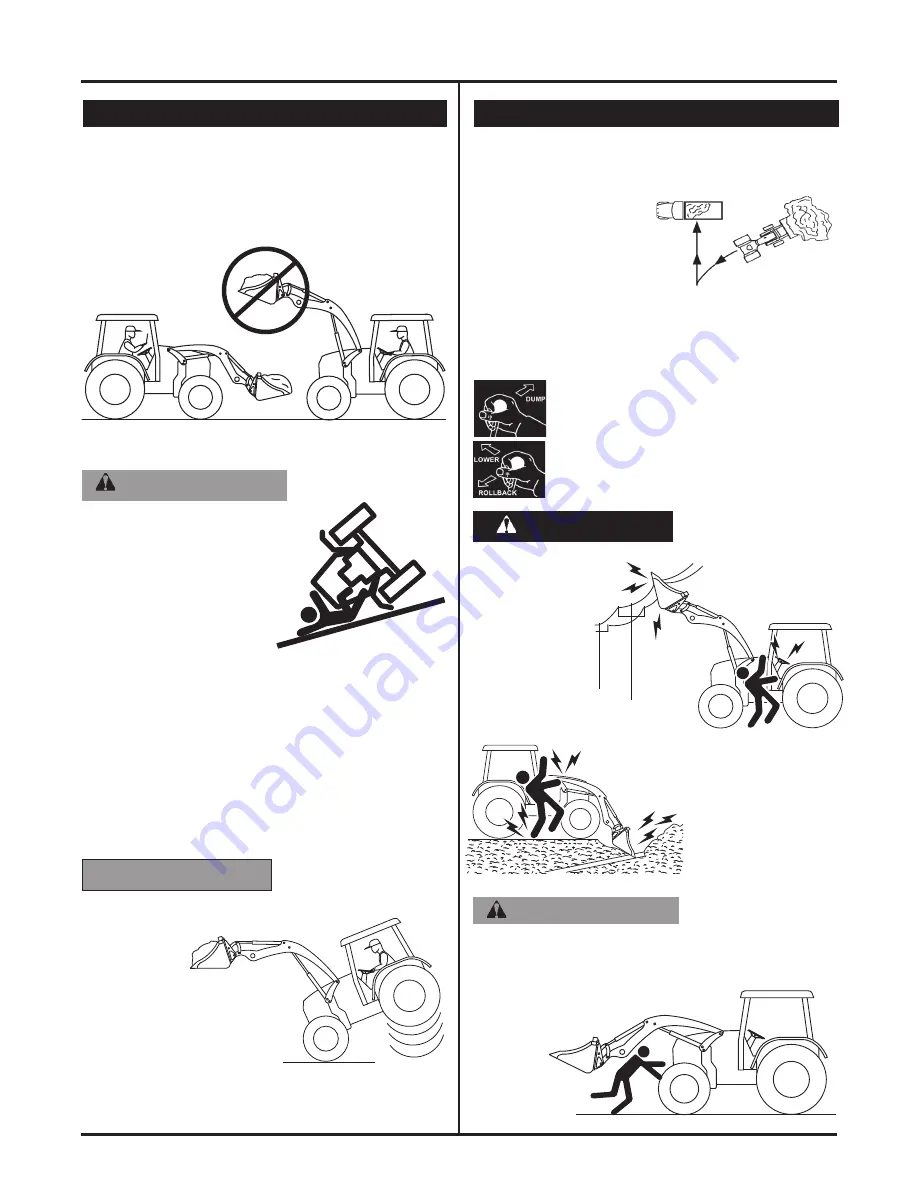

CARRY LOAD LOW DON’T CARRY HIGH

Dumping The Load

Carrying The Load

Position the load as low as possible below the level of the

tractor hood for maximum stability and visibility.

Use extreme caution when operating on a slope. Keep

the load as low as possible. This keeps the center of

gravity low and provides maximum tractor stability.

To prevent

electrocution:

•

NEVER

let

equipment

near or

contact power

lines.

• Electrocution

can occur without direct contact.

•

ALWAYS

check clearance before

raising equipment.

•

DO NOT

leave op-

erator’s seat if any

part of equipment

contacts power lines

or cables.

ELECTROCUTION

HAZARD.

DANGER

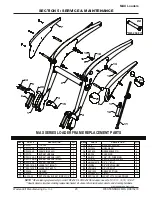

Use “V” Method For Loading

CRUSHING

HAZARD.

To prevent death or serious injury:

•

NEVER

enter area under a raised loader or attachment.

• A raised loader can fall unexpectedly,

resulting in death or serious injury.

WARNING

CRUSHING

HAZARD.

To prevent tractor roll over:

• Travel at slow speed;

• Carry loads close to the ground;

• Avoid sharp turns and sudden

movements on slopes;

• Balance load so weight is

evenly distributed and load

is stable;

• Avoid holes, ditches and other obstructions which

may cause the tractor to rollover;

• Be extra careful when operating on slopes and do not

operate on excessively steep slopes;

• Do not exceed the load capacity of your equipment;

• Be certain tractor tire spacing and rear ballast are

correct before using equipment;

• Approach large round or square bales on a slope with

the tractor facing uphill.

WARNING

LOADER DAMAGE.

NOTICE