21

Westendorf Manufacturing Co., Inc.

WESTENDORFMFG RR315270

MAX Loaders

SECTION 4: OPERATION

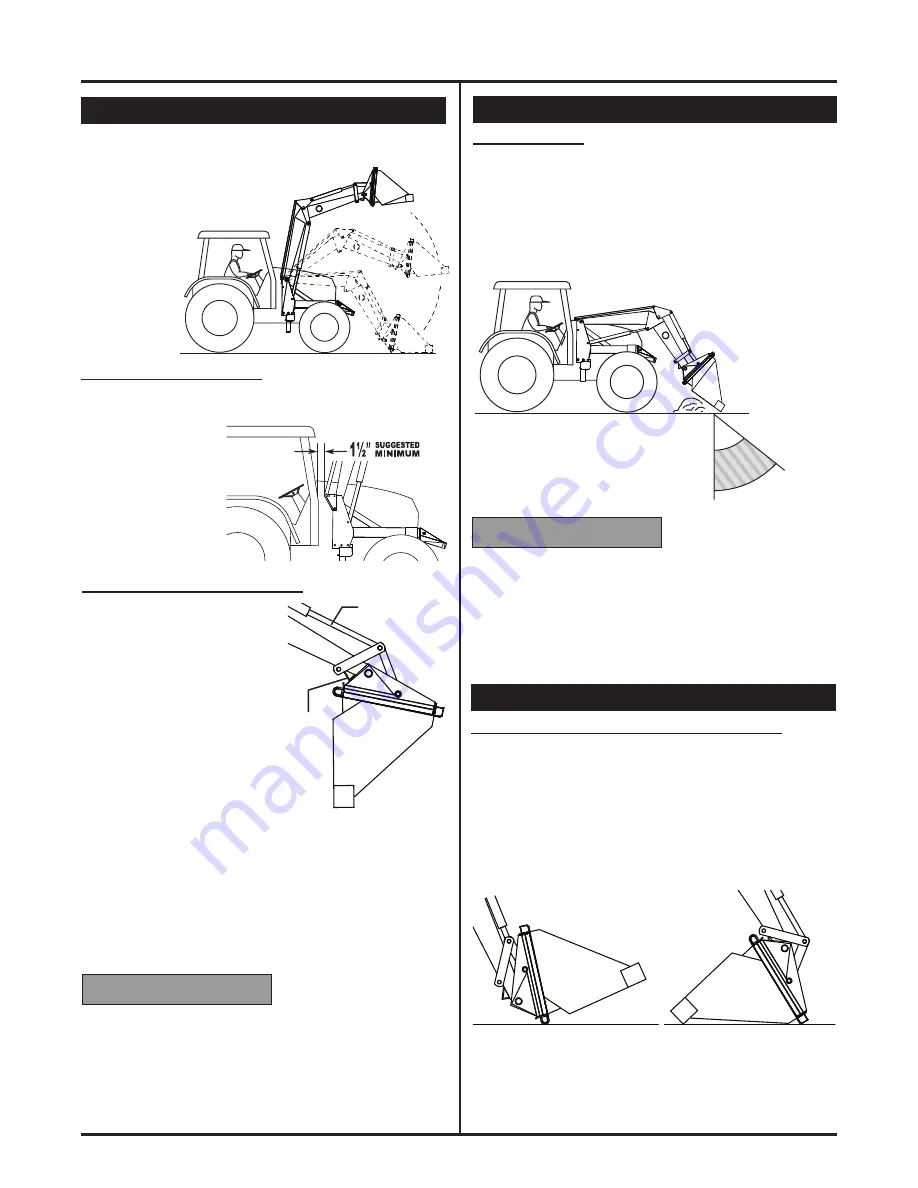

Backgrade with Self-Leveling

BACKGRADING -

When back-grading with a mechanical

self-leveling loader, be sure and keep the bucket angle

at 40° or LESS. If you go beyond the 40° you may dam-

age the loader’s self-leveling linkage from the excessive

pressure being applied against them.

Backgrade with heel of bucket only, or use optional

BACKDRAG BLADE. Place control lever in float position

so bucket follows the contour of the surface.

The mechanical self-leveling loader utilizes a system of

linkages and hinge plates that keeps the bucket in the

position you set it during operation.

You will not have to keep adjust-

ing the bucket when raising

or lowering the

loader arms.

CHECK FOR CLEARANCE -

Protect your cab during the

first time mounting of your self-leveling loader or add-on

self-leveling kit. Raise the loader slowly, as you do this,

check for clearance.

You should maintain

1-1/2” or more clear-

ance between the

rear linkage arms

and the cab when

the loader is fully

raised.

Mechanical Self-Leveling

NEVER ALLOW THIS POSITION

The self-leveling linkage will

maintain the bucket position

you set it in before you begin

raising the loader.

DO NOT

DUMP BUCKET

FULLY AND RAISE THE

LOADER. The linkage

must

move forward to function. If

the bucket is set in the fully

dumped position, the linkage

will not have room to adjust

when the loader is raised.

A built-in hydraulic relief valve on loader will relieve some

stress if the loader accidentally gets into this position.

It is not recommended to operate in this position as it

will cause damage to the self-leveling if not avoided. A

high pitched squeal is an indication that the relief valve

is bypassing and you should STOP and adjust bucket

away from the Arm Stop to prevent damage.

40°

90°

DANGER

ZONE

LOADER

DAMAGE.

To prevent loader damage:

• DO NOT fully dump the bucket and raise loader with

mechanical self-leveling loader.

• STOP if loader is squealing, adjust bucket angle away

from arm stop to avoid serious damage to loader self-

leveling linkage, loader and/or tractor.

LOADER DAMAGE.

NOTICE

INCORRECT

Bucket Cylinder

Arm

Stop

LOADER

DAMAGE.

To prevent loader damage:

• Backgrade with “heel” of bucket only, or use optional

BACKDRAG BLADE.

• Place control lever in float position to reduce down

pressure allowing bucket to follow or float along the

contour of the ground.

LOADER DAMAGE.

NOTICE

Mounting & Dismounting

DISMOUNTING A SELF-LEVELING LOADER:

When the lift cylinders are extended, allowing the front

wrap to lower to the ground, the self-leveling linkage will

reposition the bucket (trying to keep it level). To compen-

sate for this movement, set the bucket in the load carrying

position or fully rolled back when dismounting loader.

Once front wrap fully extends to ground, the bucket will be

slightly tipped forward allowing moisture to run out.

DO NOT

curl the bucket into the fully dump position and try

to dismount, this will cause the relief valve to bypass and

may cause damage to the loader or tractor.

CORRECT

INCORRECT

LOAD

CARRYING

POSITION