The WC-6X2 is a High Intensity AC Yoke, which induces a magnetic field into the

ferrous material being tested. The device should be used within the parameters set by

the operational specifications within this guide.

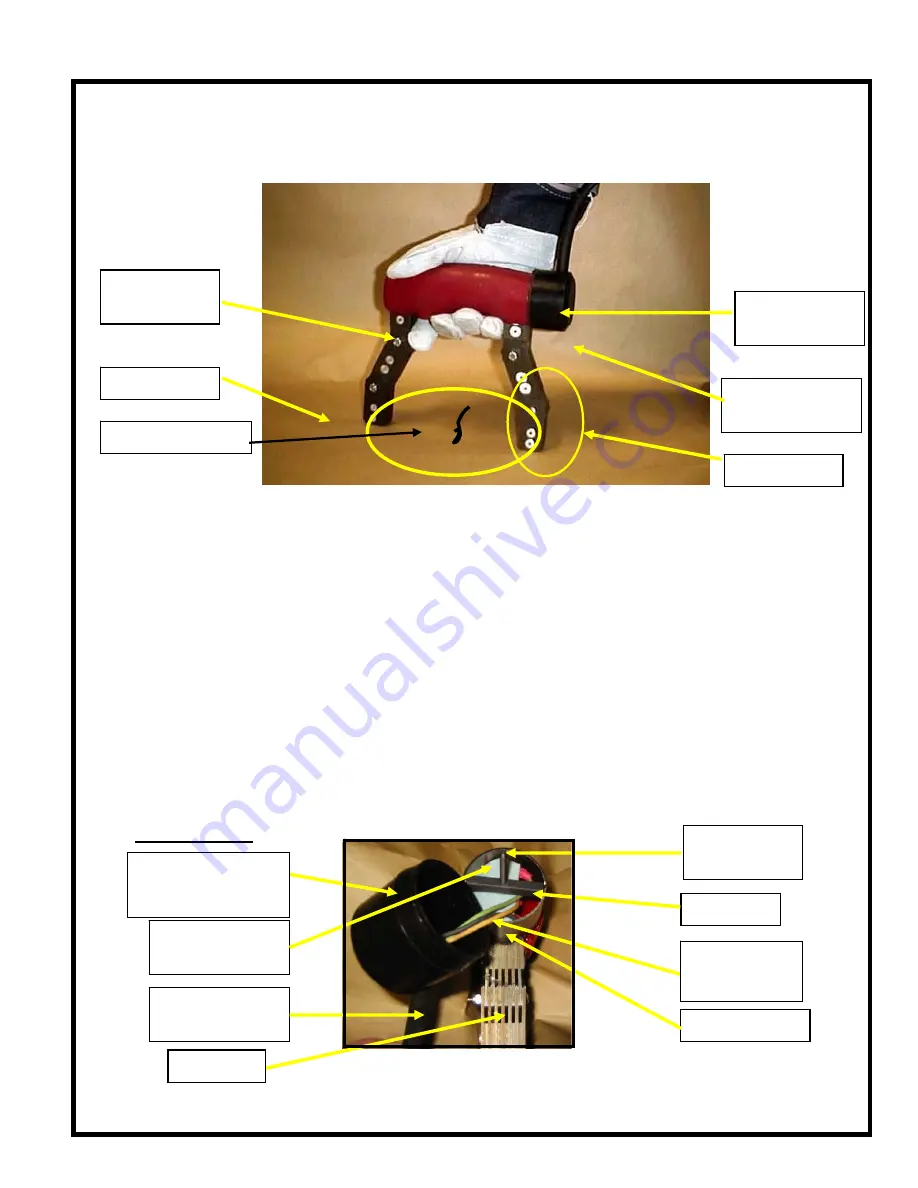

1. Solid State Push Button Switch –

The Solid State Push Button

Switch was designed for comfort and safety. While depressed, the switch delivers

power (AC) to the coil encapsulated in the Yoke housing.

Output Module, where semiconductors are used to activate

e magnetization field.

e must

t to twist or ‘pinch’ wires, on either the mounting bar or End Cap.

The Solid State Push Button Switch provides a ½ Watt control signal to the

electronic controls in the

th

itch on when plugging the Yoke into power.

Do not hold the Push Button Sw

2. End Cap Rotation –

The End Cap may be rotated to reposition the Cord

Protector (Strain Relief), for operator convenience, within the Bottom 120º or Top

120º of the Junction tube. Carefully remove the End Cap, followed by the internal

Cross Bar, and reposition the power wires. Replace the cross bar, ensuring the

insulation disk (or tape) is in place and carefully reinstall the End Cap. Car

be taken no

Bottom Exit

Push Button

Switch

Junction Tube

& End Cap

Module (inside

Junction Tube

Pole Pieces

Target Area

Crack Orie

ntation

Ground Lug

(Not used)

Cross Bar

End Cap

(Name

Plate and Fastener

not shown)

Cord Protector/

Strain Relief

Module and

Insulating Tape

Junction Tube

Power Wires

White - Positive

Black - Negative

Rear Leg

WC-6X2 Operation Manual

2