Lit. No. 49583, Rev. 02

14

June 1, 2016

OPERATIONAL TESTS AND FINAL ADJUSTMENTS

FINAL INSPECTION AND ADJUSTMENT

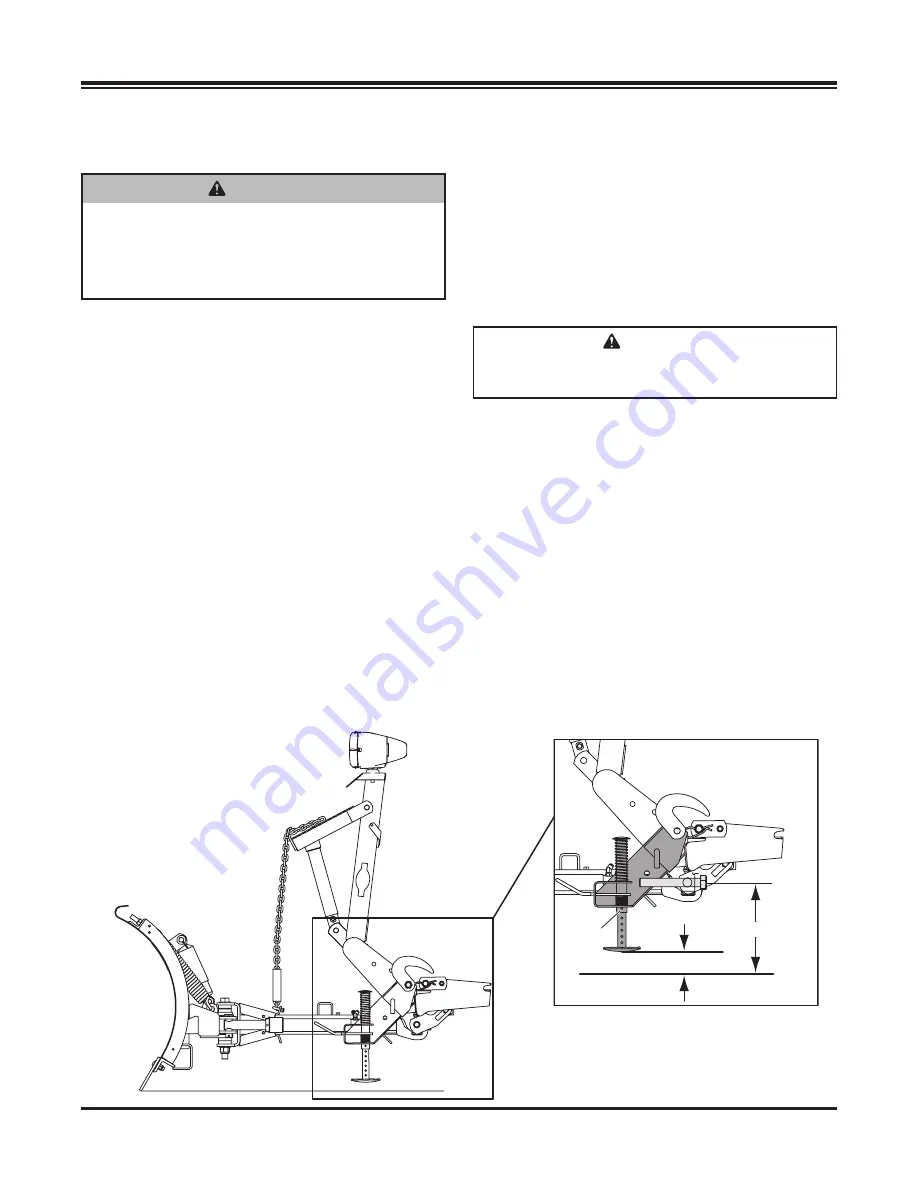

1. Attach the snowplow to the vehicle mount. With

the snowplow lowered to the ground and on

level pavement, measure the dimension from the

ground to the center of the pivot bar cap screw.

This dimension must be 9-3/4"–11-1/4".

2. With the snowplow attached and on the ground,

place the stand arm in the lower position with

the lock pin engaged and with the stand shoe

fully retracted in the "UP" position. Measure

the distance from the ground to the bottom

of the stand shoe. This distance should be

1-3/8" to 2-1/8". The stand can be adjusted to

achieve this dimension by removing the roll pin

and selecting the proper hole in the stand stem.

When the stand height is correct, cut and remove

the spring tie.

3.

Final lift chain link adjustment must be made after

the snowplow is assembled with the proper pivot

plate position. On a level surface with the blade

on the ground and the lift ram fully collapsed,

attach the chains to the lift arm hooks in the

tightest possible link. This adjustment will provide

for optimum transport height, blade float, and

stacking stop clearance. When the chain tension

is correct, the A-frame

will not

contact the lift

frame when the blade is fully raised.

4.

Check that the trip springs are adjusted correctly

by confirming that the coils of the springs are

separated slightly.

5. Adjust the trip springs by loosening the bottom

nuts and then tightening the top nuts until the

coils of the springs begin to separate (a piece of

paper such as this instruction sheet should pass

between the second and third coils). Tighten the

bottom nut against the trip spring brackets to lock

in place.

6.

Fully raise the blade and verify that it does not

block the headlamp beams. If the blade blocks the

headlamp beams, lower the blade to the ground,

collapse the lift ram and lengthen each chain by

one link. Repeat this process, lengthening the

chains by one link each time, until the blade does

not block the headlamp beams.

9-3/4" to 11-1/4"

1-3/8" to 2-1/8"

Roll Pin

PRO‑PLOW

®

Series 2

snowplow shown

WARNING

Keep 8' clear of the blade when it is being

raised, lowered or angled. Do not stand

between the vehicle and the blade or directly

in front of the blade. If the blade hits or drops

on you, you could be seriously injured.

CAUTION

Overtightening springs will not increase blade

trip force and can damage the springs.