Lit. No. 21857

June 15, 2003

21

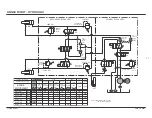

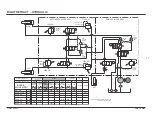

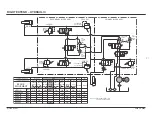

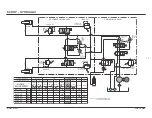

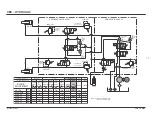

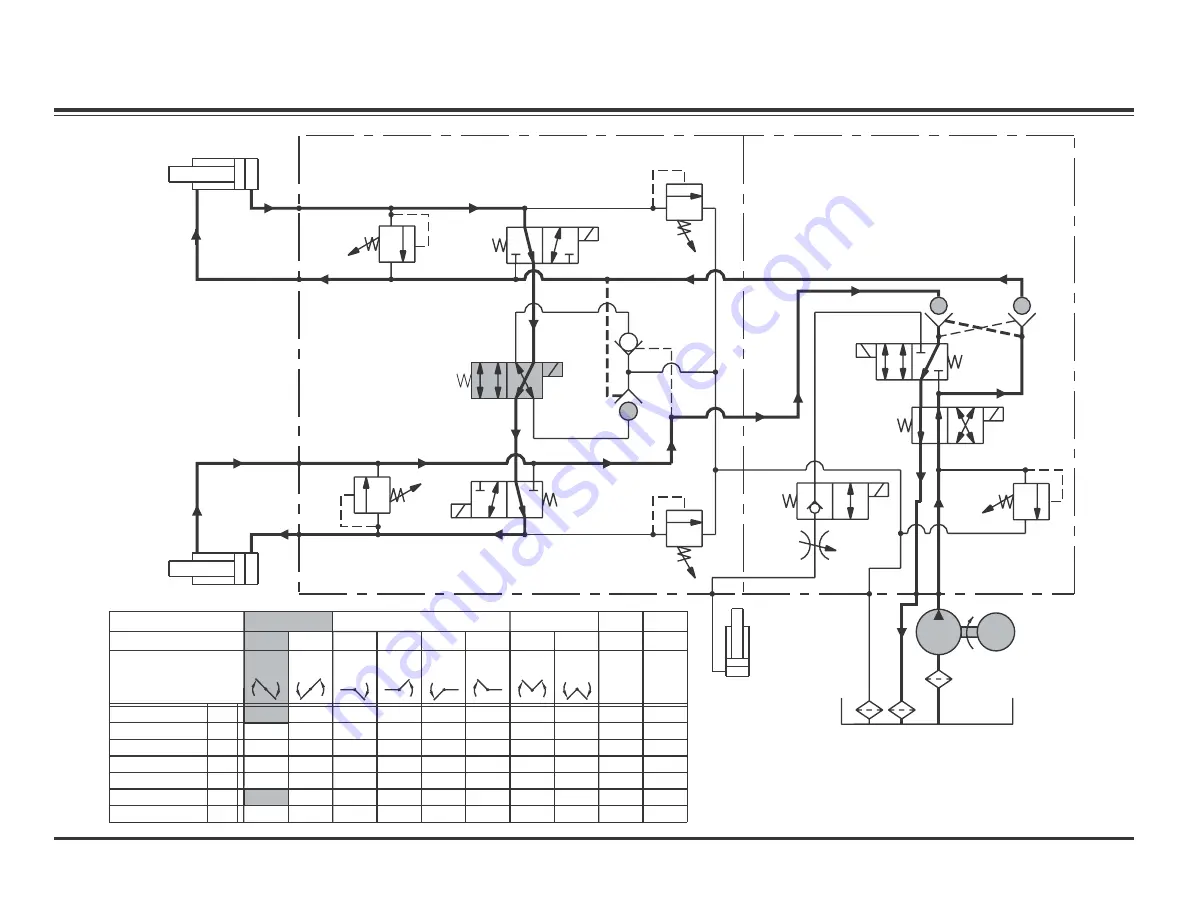

ANGLE RIGHT – HYDRAULIC

LEFT

RIGHT

3000 PSI

3000 PSI

3500 PSI

3500 PSI

1750 PSI

S6

S3

S1

S4

S2

(C)

(D)

(A)

(B)

LIFT

M

S5

ON

ON

ANGLE

RIGHT

(DEFAULT)

STRAIGHT BLADE

R/VEE

PRIMARY

RELIEF

VALVE

RELIEF VALVE

SECONDARY

VALVE

RELIEF

PUMP

RELIEF VALVE

SECONDARY

SECONDARY BLOCK ASSY.

PRIMARY BLOCK ASSY.

PRIMARY

RELIEF

VALVE

MOTOR

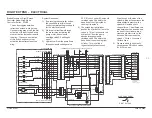

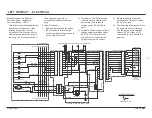

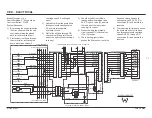

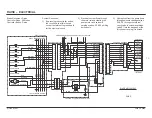

SV08-2004

SV08-40

SV08-43

SV08-40

SV08-30

S6

S5

S3

S2

S1

M

S4

SV08-30

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

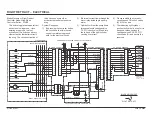

MOVEMENT

BLADE

RAISE

LOWER

ANGLE

LEFT

RIGHT

EXTEND

RIGHT

RETRACT

LEFT

RETRACT

SCOOP

VEE

L/SCP

R/VEE *

R/VEE *

WING

CONTROLLER MODE

CONTROLLER BUTTON

V / SCOOP

L/SCP *

L/SCP

R/VEE

RAISE

LOWER

ALL

ALL

* NOTE - SEE BLADE MOVEMENT TEXT

FOR BUTTON OPERATION

EXTEND

LEFT

L/SCP *

ON

ON

ON

VALVE

CHECK

P/O

VALVE

CHECK

P/O

VALVE

CHECK

P/O

VALVE

P/O CHECK