TvPe

50-D H-50

Air Circuit

Brea b"'

3.0

2/J

LO

.8

. 6

.4

.2

I

I

·'

510 20

0

400

-Std.

Ott

--- Spcl. Low

Temp. Oil

/.

Hinimum Time Delay

2.

50% Ttme Delay

3.

Haximum

Time Delay

Temp.3o·c.

40

70

Current

Amperes

800

/400

Current

Per cent

/00

2000

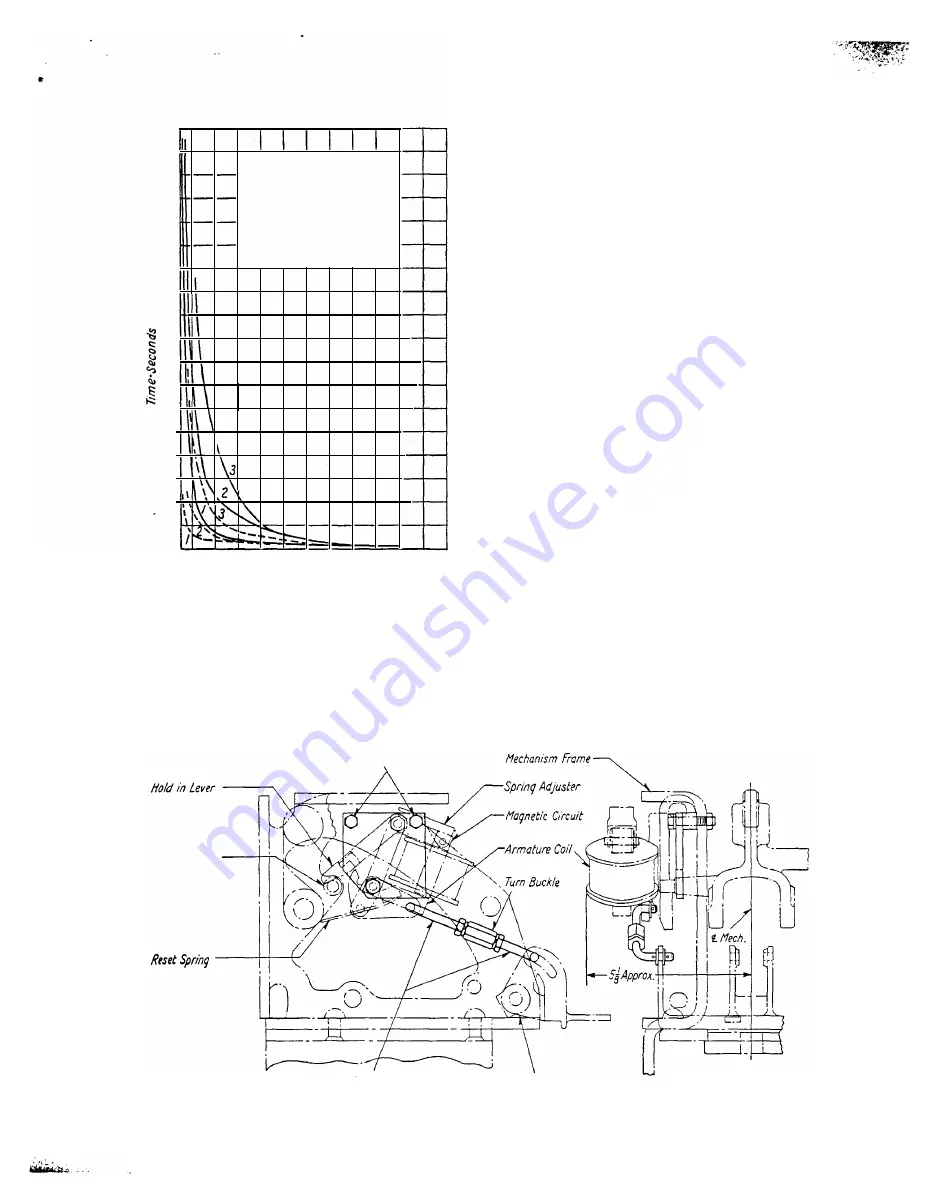

Fig. lQ-Calibration Curve for Inverse-time-limit Attachment

The oil in the dashpots should be renewed peri

odically. Fill with oil to % inch above the inside

bottom surface of the cylinder, with the plunger

removed.

Undervoltage Reset

Extension of Switch

Lrou

Undervoltaqe !1ountinq Screws

Adjusting Bolls

Undervolta�e Release

The undervoltag� release, Figure

11,

mounts

on the left hand s1de of the mechanism frame

with the two mounting screws as shown. The

undervoltage reset extension of the breaker lever

should operate between the undervoltage reset

spring and the undervol tage hold in lever. As the

mechanism closes, the reset extension of the breaker

lever strikes the undervoltage hold in lever, which

frees the undervoltage armature for operation in

case of voltage failure. As the mechanism opens.

the reset extension of the breaker lever strikes the

undervoltage reset spring, retrieving the armature

to its fully closed position. Failure to reset the

undervoltage armature completely will result in im

proper operation as the holding coil is not capable

of picking up the armature.

The turn buckle should clear the undervol tage

armature during the tripping movement. The turn

buckle should be set to secure Ys" clearance be

tween the end of the slot in the mechanism tripping

lever and the outside adjusting bolt head, with the

armature in the closed position .

The drop out voltage can be varied by regulating

the extension of the two undervoltage tripping

springs. A similar design, larger than shown by

Fig. 11, is used on later applications.

Cut-Off Switch

The 50-DH-50 Air Circuit Breaker has been sup

plied with two types of cut-off switches.

The cut-off switch supplied on the earlier models

is mounted on the left side of the mechanism just

back of the undervoltage attachment, Figure

12,

page

13.

It is a normally closed switch that is held

in the open position by means of an auxiliary

compression spring which acts on the auxiliary

switch lever. During the last portion of the closing

stroke the moving core strikes the switch pin which

ffechanism Trip Lever

Fig. 11-Undervoltage Operating Assembly

12

•

•

•

www

. ElectricalPartManuals

. com