18 | Westinghouse Outdoor Power Equipment, LLC

Westinghouse Outdoor Power Equipment, LLC | 19

MAINTENANCE

NOTICE

DO NOT twist or tear the foam air filter element during

cleaning or drying. Only apply slow but firm squeezing

action.

5.

Rinse the air filter element by submerging it in fresh

water and applying a slow squeezing action. Allow the

filter to dry thoroughly.

NOTICE

Do not pollute. Follow the guidelines of the EPA or other

governmental agencies for proper disposal of hazardous

materials. Consult local authorities or reclamation facility.

6.

Dip the foam air filter in clean engine oil then squeeze

out all excess oil. The engine will smoke when started if

too much oil is left in the filter.

7.

Install the foam air filter in the housing and reinstall the

air cleaner cover.

8.

Install the engine service panel.

Air Filter: Part# 5291

ENGINE OIL LEVEL CHECK

CAUTION

Avoid skin contact with engine oil. Wear protective

clothing and equipment. Wash all exposed skin with

soap and water.

NOTICE

Always use the specified engine oil. Failure to use the

specified engine oil can cause accelerated wear and/or

shorten the life of the engine.

When using the generator under extreme, dirty, dusty

conditions or in extremely hot weather, change the oil

more frequently.

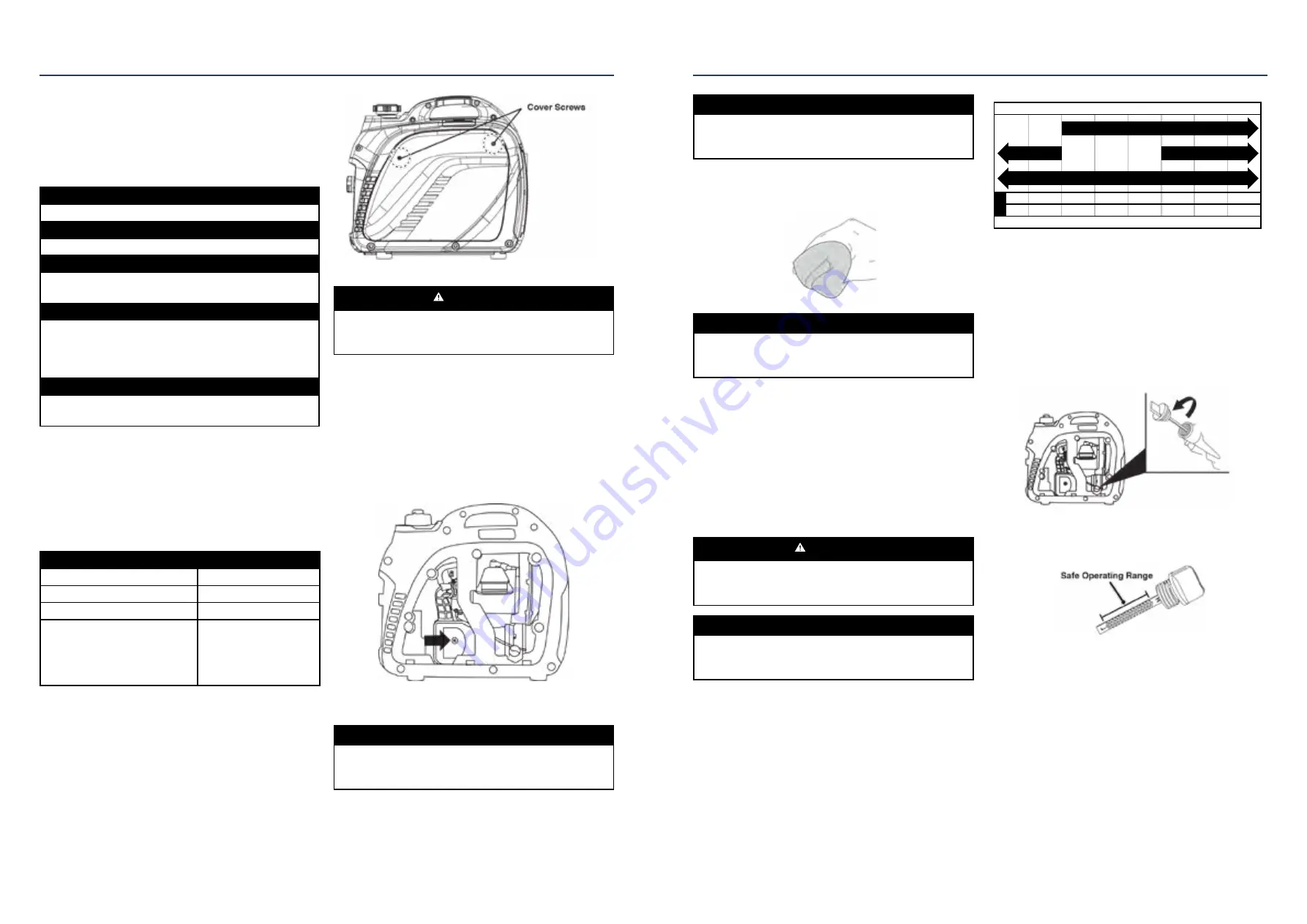

Ambient air temperature will affect engine oil performance.

Change the type of engine oil used based on weather

conditions.

-20

0

20

40

60

Ambient temperature

Recommended Engine Oil Type

80

100

120

-28.9

°F

°C

-17.8 -6.7 4.4

15.6 26.7 37.8 48.9

10W-30

5W-30 Synthetic

10W-40

5W-30

Check the engine oil level before each use or every 8

hours of operation.

1.

Place the generator on a level surface and allow the

engine to cool for several minutes.

2.

Remove the engine service cover.

3.

With a damp rag, clean around the oil dipstick.

4.

Remove the oil dipstick and wipe the dipstick clean.

5.

Screw the dipstick fully into the filler neck. Remove

the dipstick and verify that the oil level is within safe

operating range.

6.

If low, add recommended engine oil incrementally and

recheck until the level is between the L and H marks on

the dipstick. DO NOT overfill. If over the full mark on

dipstick, drain the oil to reduce oil level to the full mark

on dipstick.

7.

Replace the oil dipstick and hand-tighten.

8.

Install the engine service cover.

MAINTENANCE

MAINTENANCE SCHEDULE

Regular maintenance will improve performance and

extend the service life of the generator. Follow the hourly

or calendar intervals, whichever occurs first. More frequent

service is required when operating in adverse conditions

as noted below.

Before Each Use

Check engine oil

After First 25 Hours or First Month

Change engine oil

After 50 Hours or Every 6 Months

Change engine oil

1

Clean air filter

2

After 100 Hours or Every 6 Months

Inspect/clean spark arrestor

Inspect/clean spark plug

Replace fuel filter

3

Inspect/adjust valve clearance

3

After 300 Hours or Every Year

Replace spark plug

Replace air filter

1

Change oil every month when operating under heavy

load or in high temperatures.

2

Clean more often under dirty or dusty conditions.

Replace air filter if it cannot be adequately cleaned.

3

Recommend service to be performed by authorized

Westinghouse service dealer.

MAINTENANCE REPLACEMENT PARTS

Description

Part Number

Air filter

5291

Spark arrestor

6789

Fuel filter

516401

Spark plug

• Torch - E6RTC

•

NGK - BPR6HS

• Bosch - WR7BC

• Autolite - 284

ENGINE SERVICE COVER

Remove the engine service cover to access the air filter,

carburetor, oil fill/drain, and oil dipstick. Remove the two

cover screws then carefully pull the cover out with both

hands to prevent damage to the grommet posts on the

cover.

AIR FILTER MAINTENANCE

WARNING

Fire hazard. Never use gasoline or other flammable

solvents to clean the air filter. Use only household

detergent soap to clean the air filter.

The air filter must be cleaned after every 50 hours of use or

six months (frequency should be increased if the generator

is operated in a dusty environment).

1.

Place the generator on a level surface and allow the

engine to cool for several minutes.

2.

Remove the engine service cover.

3.

Remove the screw securing the air cleaner cover. Tip

the cover down to remove.

Note:

The air filter element is oil soaked. Use an

appropriate cleaning container.

NOTICE

Avoid skin contact with engine oil. Wear protective

clothing and equipment. Wash all exposed skin with

soap and water.

4.

Remove the foam air filter from the air cleaner housing

and wash it by submerging the element in a solution

of household detergent soap and warm water. Slowly

squeeze the foam to thoroughly clean.