10 | Westinghouse Outdoor Power Equipment, LLC

Westinghouse Outdoor Power Equipment, LLC | 11

ASSEMBLY

FUEL

WARNING

Fire and explosion hazard. Never use a gasoline

container, gasoline tank, or any other fuel item that is

broken, cut, torn or damaged.

DANGER

Fire and explosion hazard. Do not overfill fuel tank. Fill

only to the red fill ring located in the in-tank fuel screen

filter. Overfilling may cause fuel to spill onto engine

causing a fire or explosion hazard.

DANGER

Fire and explosion hazard. Never refuel the generator

while the engine is running. Always turn the engine off

and allow the generator to cool for two minutes before

refueling.

NOTICE

E85 E15

Do not use E15 or E85 fuel in this

product. Engine or equipment

damage caused by stale fuel or

the use of unapproved fuels (such

as E15 or E85 ethanol blends) is

not covered by warranty. Only use

unleaded gasoline containing up to

10% ethanol.

FUEL REQUIREMENTS

•

CLEAN, FRESH, unleaded gasoline, 87–93 octane.

•

Up to 10% ethanol (gasohol) is acceptable (where

available; non-ethanol fuel is recommended).

•

DO NOT use E85 or E15.

•

DO NOT use a gas oil mix.

•

DO NOT modify the engine to run on alternate fuels.

•

DO NOT fuel indoors.

•

DO NOT create a spark or flame while fueling.

USING FUEL STABILIZER

Adding a fuel stabilizer (not included) extends the usable

life of fuel and helps prevent deposits from forming that

can clog the fuel system. Follow the manufacturer’s

instructions for use.

Always mix the correct amount of fuel stabilizer to gasoline

in an approved gasoline container before fueling the

generator. Run the generator for five minutes to allow the

stabilizer to treat the entire fuel system.

FILLING THE FUEL TANK

1.

Turn the generator OFF and allow to cool for a minimum

of two minutes before fueling.

2.

Place the generator on level ground in a well ventilated

area.

3.

Clean the area around fuel cap and remove the cap

slowly.

NOTICE

Only fill the tank from an approved gasoline container.

Make sure the gasoline container is internally clean and

in good condition to prevent fuel system contamination.

4.

Slowly add the recommended fuel. Do not overfill. Fill

only to the red maximum fill ring on the fuel screen filter

visible in the filler neck.

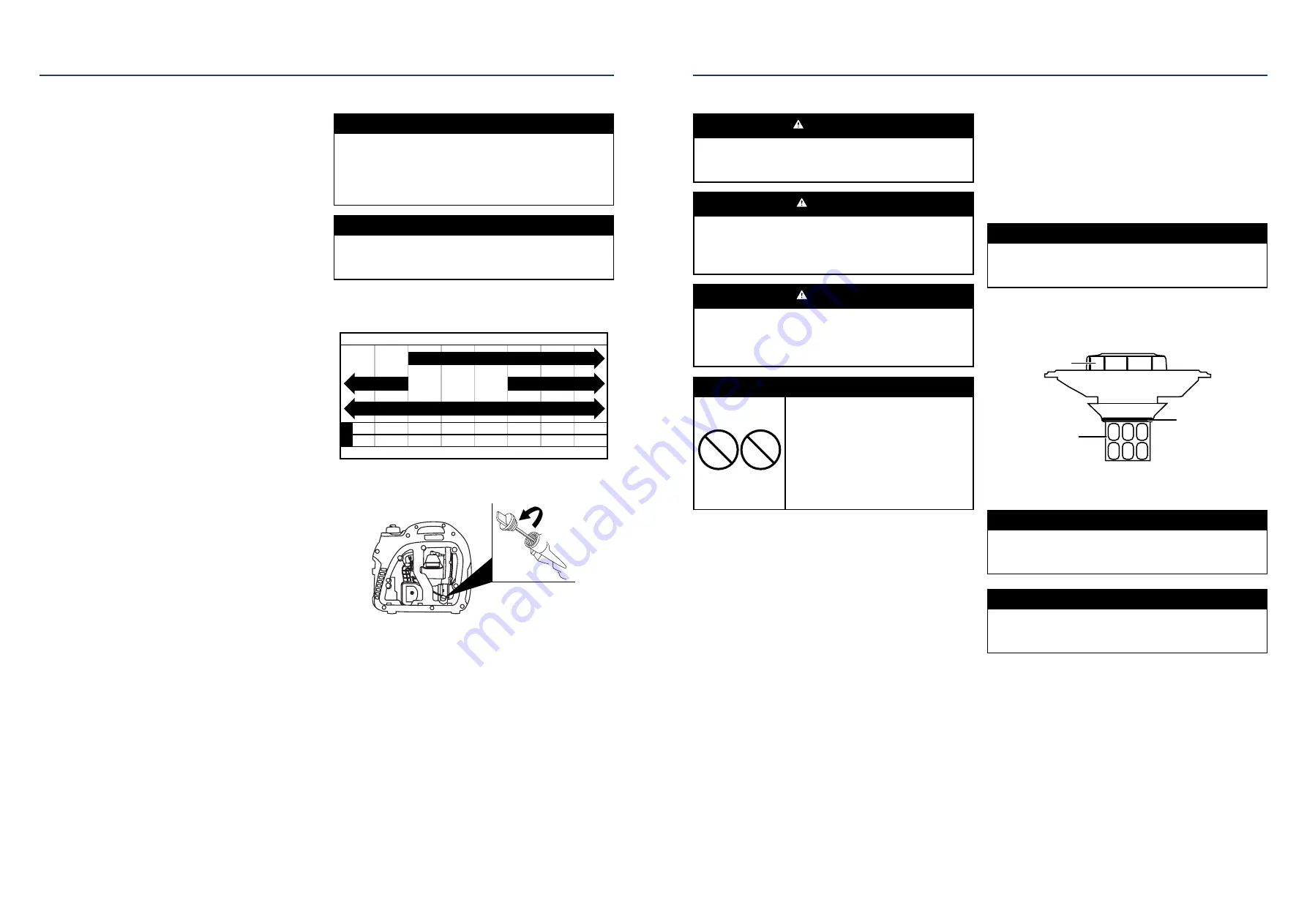

Maximum

Fuel Level

Screen

Filter

Fuel Cap

5.

Install the fuel cap. Tighten until a click is heard

(iGen2500 only).

NOTICE

Fuel can damage paint and plastic. Use caution when

filling the fuel tank. Damage caused by spilled fuel is not

covered under warranty.

NOTICE

Clean the fuel screen filter of debris before and after

each fueling. Remove the fuel screen filter by slightly

compressing it while removing it from the fuel tank.

ASSEMBLY

CARTON CONTENTS

1.

Carefully open the carton.

2.

Remove and save the instruction manual, oil bottle, oil

funnel, spark plug socket wrench, and screwdriver.

3.

Remove and discard the packing materials.

4.

Unfold the top of the plastic bag enclosing the generator.

5.

Carefully cut the vertical corners of the carton to access

the generator.

6.

Recycle or dispose of the packaging materials properly.

CARTON CONTENTS

• User manual

•

Quick Start Guide/Maintenance Schedule

• 0.37 Quart (0.35 Liter) bottle of SAE 10W-30 Oil

• Screwdriver

• Spark plug socket wrench

• Oil Funnel

If any parts are missing, contact our service team at

service@wpowereq.com or call 1-855-944-3571.

INITIAL OIL FILL

NOTICE

THIS GENERATOR HAS BEEN SHIPPED WITHOUT

OIL

. Do not attempt to crank or start engine before it has

been properly serviced with recommended oil. Failure to

add engine oil before starting will result in serious engine

damage.

NOTICE

Use of 2-stroke/cycle oil or other unapproved oil types

can cause severe engine damage that is not covered

under warranty.

The included, recommended oil type for typical use is

10W-30 engine oil. If running the generator in extreme

temperatures, refer to the following chart.

-20

0

20

40

60

Ambient temperature

Recommended Engine Oil Type

80

100

120

-28.9

°F

°C

-17.8 -6.7 4.4

15.6 26.7 37.8 48.9

10W-30

5W-30 Synthetic

10W-40

5W-30

1.

On a level surface, remove the engine service cover

and oil dipstick.

2.

Using the supplied funnel and oil, add oil into the engine.

Note:

As residual oil from the factory may remain in the

engine, add the oil incrementally near the end of the

bottle to prevent overfilling the engine. See Engine

Oil Level Check in the Maintenance section.

3.

Replace the oil dipstick and hand-tighten.

4.

Replace the engine service cover.