16 | Westinghouse Outdoor Power Equipment, LLC

Westinghouse Outdoor Power Equipment, LLC | 17

OPERATION

PARALLEL OPERATION

WARNING

Fire and electrocution hazard. Never connect or

disconnect the parallel cord leads when a generator is

running.

NOTICE

Connecting to a generator that is not compatible can

cause a low voltage output that can damage tools and

appliances powered by the generator.

Parallel operation gives you the ability to link the iGen2200

or iGen2500 to a compatible Westinghouse Inverter

Generator for combined running and peak power output.

A Westinghouse parallel cord (purchased separately) is

required for parallel operation. This cord can be purchased

from an authorized Westinghouse Generator dealer.

Note:

Do not use ECO MODE when in parallel operation

with another Westinghouse generator.

Parallel cord: Part# 507PC

Note:

Compatible Westinghouse generators without

parallel ports can be operated in parallel with the

receptacle-mounted parallel cable, Part# 260041.

The iGen2200 and iGen2500 are

parallel-operation

compatible with the following Westinghouse inverter

generators:

• iGen2200

• iGen2300

• iGen2500

• IGen2600

• IGen4500

1.

On both generators, make sure the fuel switch and the

ECO MODE switch are in the OFF position.

2.

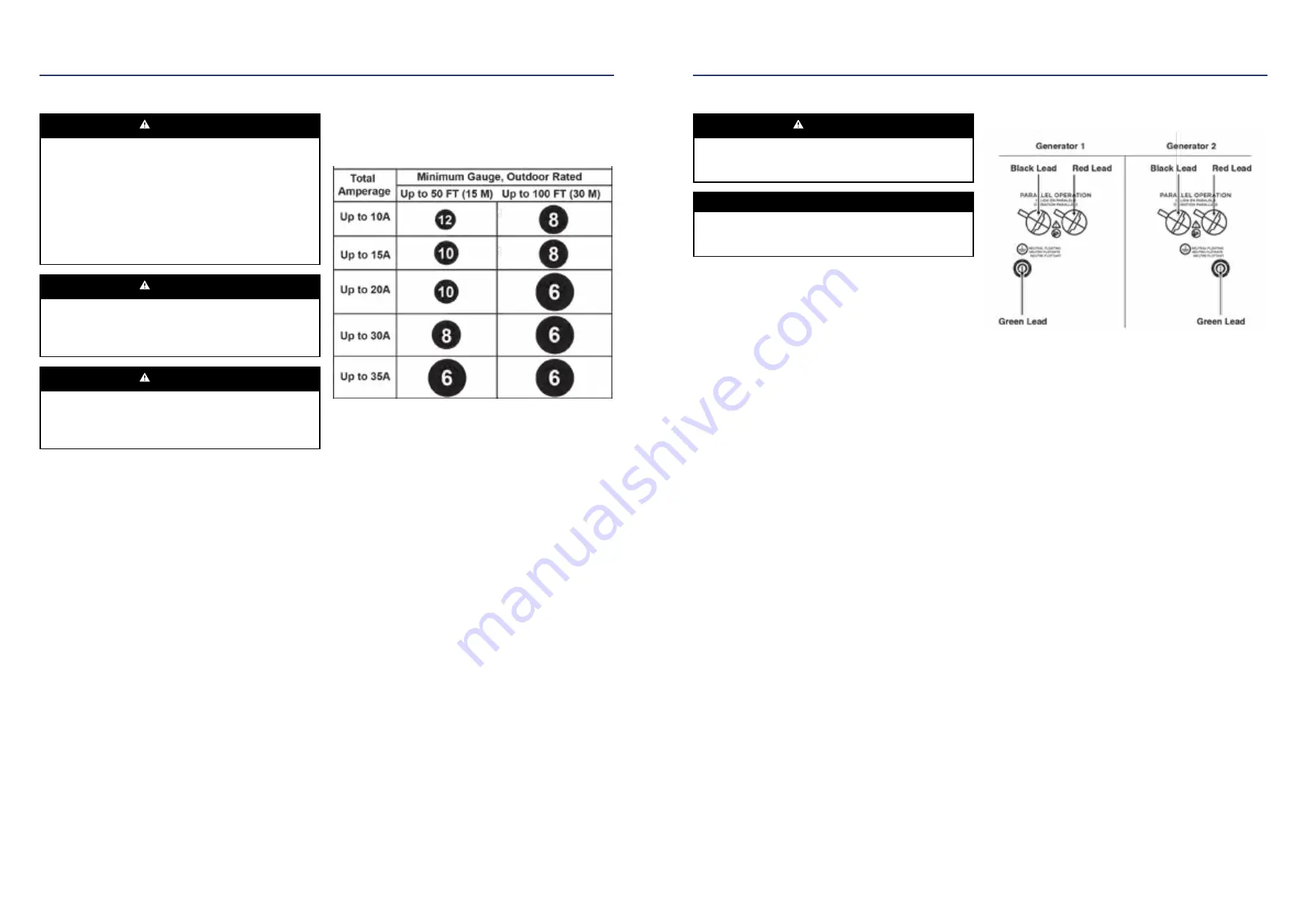

Connect a black and red parallel cable lead to each

generator. Connect the black lead to the left port, the

red lead to the right port.

Note:

DO NOT connect two red leads or two black leads

into the same generator.

3.

Connect the green ground lead to the ground terminal

on each generator and tighten the nut.

4.

Start one of the generators and wait until the OUTPUT

READY LED illuminates.

5.

Start the second generator and wait until the OUTPUT

READY LED illuminates before connecting a load.

6.

Connect additional loads as described in Power

Management section.

7.

Unplug all loads before stopping the generators.

TRANSPORTING

• Allow the generator to cool a minimum of 30 minutes

before transporting.

• Replace all protective covers on the generator control

panel.

•

Only use the generator’s fixed handle to lift the unit or

attach any load restraints such as ropes or tie-down

straps. Do not attempt to lift or secure the generator by

holding onto any of its other components.

• Keep the unit level during transport to minimize the

possibility of fuel leakage or, if possible, drain the fuel

or run the engine until the fuel tank is empty before

transport.

OPERATION

EXTENSION CORDS

WARNING

Asphyxiation hazard. Extension cords running directly

into the home increase the risk of carbon monoxide

poisoning through any openings. If an extension cord

running directly into your home is used to power indoor

items, there is a risk of carbon monoxide poisoning to

people inside the home. Always use battery-powered

carbon monoxide detector (s) that meet current UL 2034

safety standards when running the generator. Regularly

check the detector (s) battery.

WARNING

Asphyxiation hazard. When operating the generator with

extension cords, make sure the generator is located in an

open, outdoor area, at least 20 ft. (6 m.) from occupied

spaces with exhaust pointed away.

WARNING

Fire and electrocution hazard. Never use worn or

damaged extension cords. Damaged or overloaded

extension cords could overheat, arc, and burn resulting

in death or serious injury.

Before connecting an AC appliance or power cord to the

generator:

• Use grounded 3-prong extension cords, tools, and

appliances, or double-insulated tools and appliances.

• Make sure the tool or appliance is in good working

order. Faulty appliances or power cords can create a

potential for electric shock.

• Make sure the electrical rating of the tool or appliance

does not exceed the rated power of the generator or the

receptacle being used.

EXTENSION CORD SIZING

Only use grounded 3-prong extension cords marked for

outdoor use that are rated for the electrical load.