18

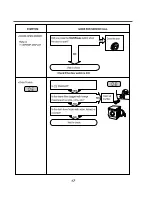

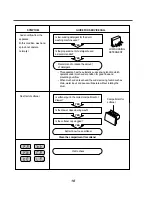

SYMPTOM GUIDE FOR SERVICE CALL

°

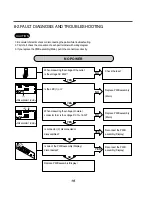

Suds overflow from the

appliance.

(In this condition, wash and

spin do not operate

normally)

°

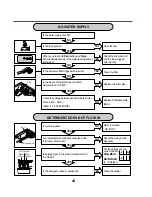

No effect of softener

YES

YES

YES

YES

YES

Is low-sudsing detergent for the durm

washing machine used?

Is the proper amount of detergent used

as recommended?

Recommend to reduce the amount

of detergent.

Is softener put in the correct compartment of

drawer?

Is the drawer closed during wash?

Is the softener cap clogged?

Explain how to use softener

Clean the compartment for softener

Visit to check

LOW SUDSING

DETERGENT

Compartment for

softener

This appliance has the automatic suds sensing function which

operates under much suds condition for good rinse and

preventing overflow.

When much suds are sensed, the suds removing fuction such as

drain, water input, and pause will operate without rotating the

drum.

Summary of Contents for LF 708C

Page 2: ...Aug 2002 PRINTED IN KOREA P No 3828ER3013H...

Page 18: ...17...