sealed at the factory and need no lubrication for the life

of the motor.

5 .

The control wiring should be ch ecked for integrity of

insulation. The conduit and control cabinet should be

checked to assure that they are weatherproof. Control

power supply voltage should be checked with respect to

the wiring diagram.

6.

Inspect the paint finish for scratches or wear that ex

pose the prime coat or the tank steel itself. Repair paint

flaws as soon as prac tical. Local climates vary too widely

to give definite recommendations as to frequency of re

painting.

7.

Using an infrared scanner , inspect the operating trans

former's surface temperature. Be sure to check bushing

terminals and cooling fins. At

5 0%

or less of rated load,

uneven heat distribution on cooling fins is common. Any

unusually hot or cold surface should be investigated.

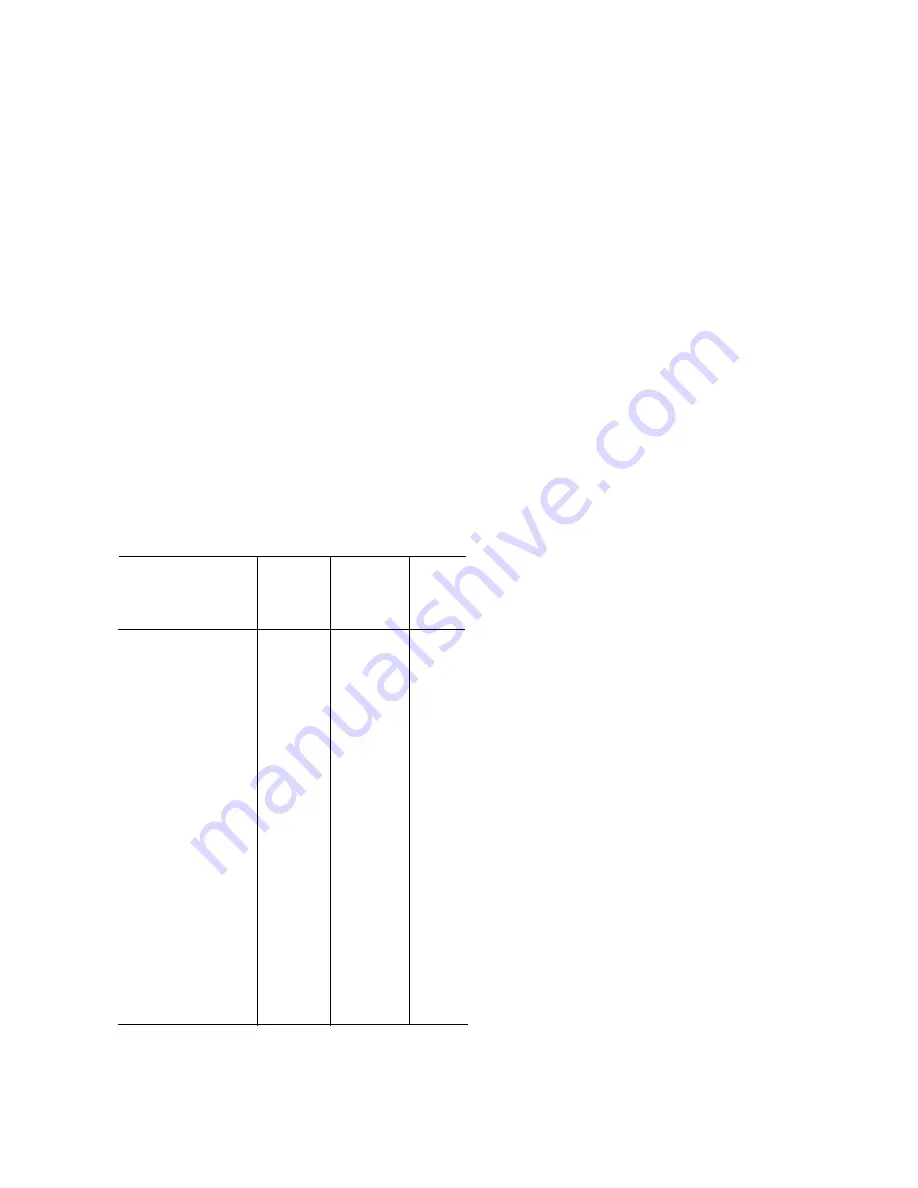

Table

3 .

Recommended Maintenance Schedule

Just Prior One Month Once

To

After

a

Check Period

Energizing Energizing Year

1. Gauge Readings

X

X

X

2 .

Bolted Con-

nections

X

3.

Tank Leaks

X

X

4.

Fan Operation

X

X

5 .

Control Wiring

&

Circuits

X

X

6.

Paint Finish

X

X

7 .

Surface

Temperature

with Infrared

Scanner

X

X

8.

Liquid Dielectric

Test

X

X

8 .

Liquid Dielectric Test. It is recommended that a liquid

sample be taken periodically and tested. The dielectric

strength of the liquid should not drop below

26

Kv.

27

If the dielectric strength drops below

22

Kv, the liquid

should be filtered. Sampling and testing procedures can

be found i n Instruction Book

45-063 - 1 00

for OIL,

LB.

45 -063 - 1 02

for SILICONE FLU ID, and LB.

47-05 3-1

for WEMCO " FR" insulating oil.

8.2 Sampling of Insulating Liquid

Care should be taken to procure a sample which fairly

represents the liquid in the tank. A sufficient amount of

liquid should therefore be drawn off before the sample is

taken to insure that the sample will not be that which is

stored in the sampling pipe. If the sample taken contains

free water , it is not suitable for dielectric tests and the

sample should be discarded. A second sample should then

be taken after at least two quarts of liquid have been

wi thdrawn. If free water still exists , the liquid should be

run through a blotter filter press and re-tested for di

electric strength .

The sample of the liquid should be taken when the unit

is warmer than the surroundings to avoid condensation

and should also be taken only on clear days.

When sampling O IL from the transformer, the sample

must come from the bottom of the tank.

When sampling SILICONE FLUID from the trans·

former , the sample may come from either the top liquid

level or the bottom of the tank.

It is recommended that a 16 -ounce amber glass con

tainer be used as a sampling receptacle so that any water

present may readily be seen. Do not use rubber gaskets

or stoppers on SIL ICONE FLUID sample bottles.

Additional information concerning handling, sampling ,

filtering , testing and reconditioning can be obtained by

ordering Instruction Book

45-063- 1 00

for OIL, Instruc

tion Book

45 -063 - 1 02

for SIL ICONE FLUID and Instruc

tion Book

47-053-1

for WEMCO "FR" through the near

est Westinghouse Sales Office.

8.3

Drying of Transformer

Occasionally , moisture will be absorbed in the windings

and insulation which a liquid filtering process will not re

move . Whether the windings must also be dried after the

liquid fl.ltering process is determined by an insulation re

sistance test. The measured insulation resistance should

be compared to factory test values. If that data is not

available, use the values in Figures

1 8

and

1 9

as a guide.