6

ENGLISH

QKG06

Web: www.conglom.com/documentation/

Installation (continued)

INSTALLATION OF MOUNTING ASSEMBLY

Top supporting ring

Top supporting ring screw

Fig. 5a

Fig. 5b

Flange

Flange ring

Supporting

plate

Gasket

Plumber’s

Putty

Sink flange

Recommended

Sink

Fig. 7a

Fig. 7b

Supporting

plate

Gasket

Sink

flange

Sink

Fig. 7

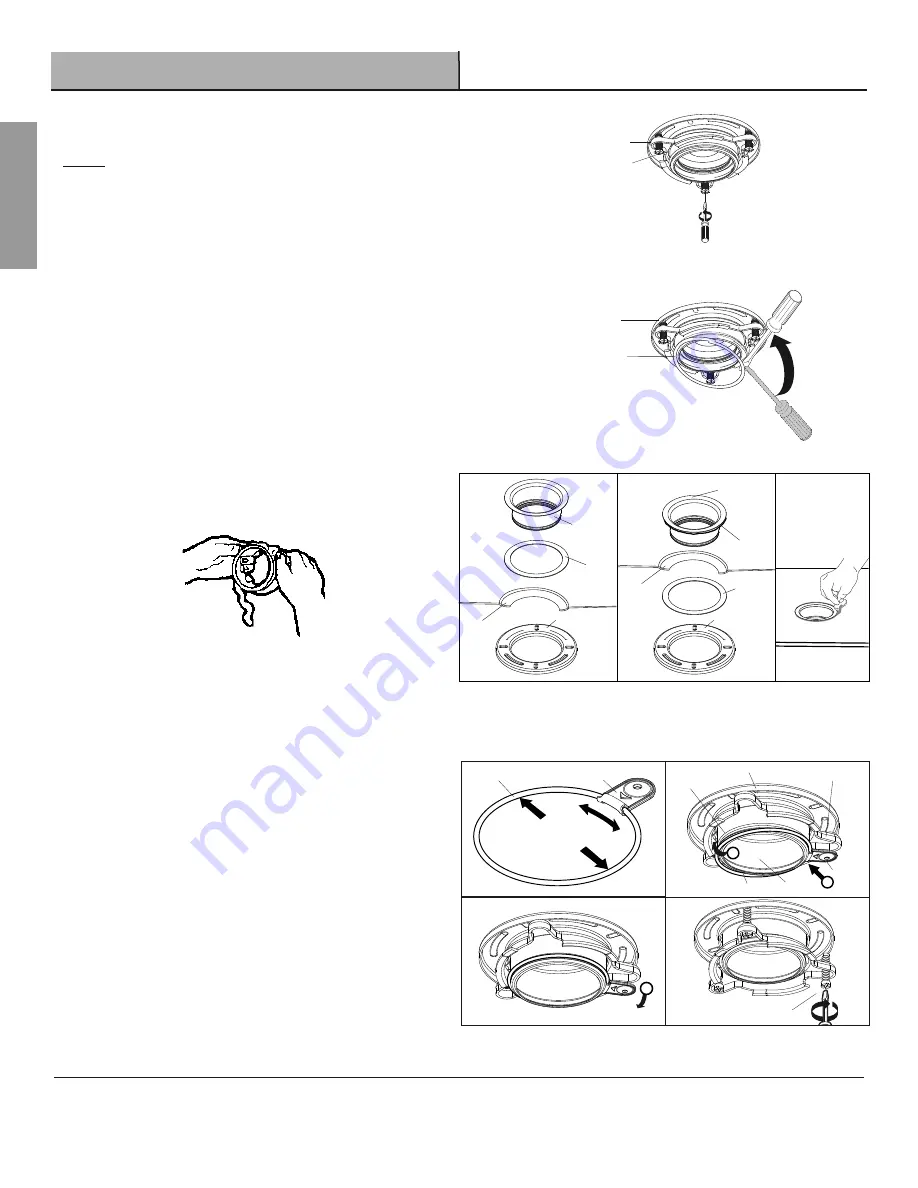

NOTE:

Pay close attention how the parts come assembled, as they have been

correctly assembled by the factory (see Fig. 5).

This food waste disposer has been designed to operate on 110-120 Volt,

60 Hz electrical circuit.

- Disassemble the mounting assembly from the disposer by turning

the bottom supporting ring clockwise.

- Loosen the 3 screws all the way or remove them from the top

supporting ring (Fig. 5a), then use a screw driver to remove the

flange ring (Fig. 5b).

-

The sink flange may be installed with or without use of plumber’s

putty (see Fig 7 and 7a).

If you use putty, (see Fig. 7a) form a ring around the underside of

the sink flange (see Fig. 6). Insert the flange into the sink opening,

press down hard to squeeze out the excess putty. Trim off excess

putty from the top and bottom of the sink opening (see Fig. 7b). Do

not rotate the flange once it is seated.

Fig. 6

-

Use duct tape or place a heavy object on top of the sink flange to

keep it in place.

-

Stretch the flange ring and insert the ends securely into the ring

tool. Keep your fingers away from the ends of the flange ring at all

times (see Fig. 8).

- Insert the supporting plate and the top supporting ring and hold

them in place. Place the ring tool in the groove of the sink flange

with the arrow side towards you facing towards the bottom. Using

your thumb, push the opposite end of the flange ring until it snaps

into the groove of the sink flange (see Fig. 8a).

- Release the ring tool by rotating it downwards until it snaps away

from the flange ring (see Fig. 8b).

- Tighten the 3 top supporting ring screws sequentially until the

flange is very securely fastened to the sink (see Fig. 8c)

Top supporting ring

Ring tool

Supporting plate

Flange ring

Sink flange

Groove of

sink flange

Fig. 8a

1

2

Fig. 8

3

Fig. 8b

Fig. 8c

Ring tool

Flange ring

Top supporting

ring screw