78

WHL-016 REV. 12.18.14

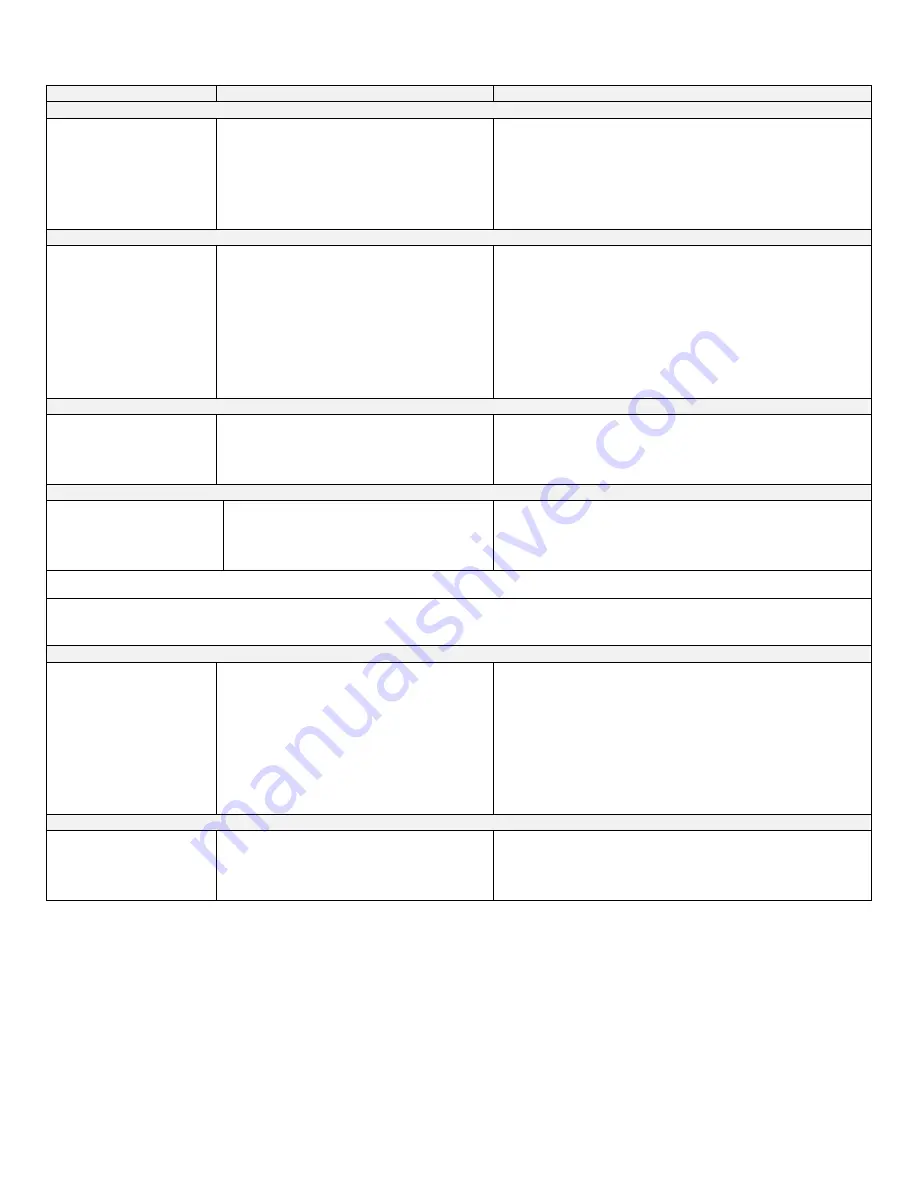

SCREEN

DESCRIPTION

POSSIBLE REMEDY

Fault Code F20

CONDENSATE FULL F20

PUMP ON

The condensate trap is full. The red light will

display and the word LOCKOUT will flash. This

code indicates a serious safety issue. The boiler

will not restart until the cause is determined by a

technician and he pushes the RESET button on

the display. During this lockout fault, the pump

will be off as indicated on the second line of the

display.

1. Check condensate lines for obstructions.

2. Check wiring from condensate reservoir to 926 control. Verify the

leads are green and red. Repair as necessary.

Fault Code F31

PROGRAM ERROR

F31

There was an error while programming the con-

trol and the memory is corrupt. The boiler control

will not function in this state and the pump will be

off as indicated on the bottom line. This error

only occurs if a technician is programming the

control and the programming function fails. The

only way to recover from this error is to repro-

gram the control. If this error occurs at any time

other than when a technician is servicing the

boiler, the control has failed and must be

replaced by a qualified technician

The control must be re-programmed. If programming does not solve

problem, the control must be replaced.

Fault Code PP

CONTROL PROGRAMED

PP

The control has been programmed by a

technician or the factory. After programming, the

control is left in a locked out mode. Press the

RESET key for at least 1 second to begin use of

the control.

Fault Code FOU

OUTDOOR SENSOR FOU

PUMP ON 1:45P

There is an issue with the outdoor sensor. It is

shorted, damaged, or disconnected from the

boiler.

1. Check outdoor sensor connections and wiring. Ensure the sensor

and wiring are intact and that the sensor is connected to the boiler.

2. Check the outdoor sensor resistance with an ohmmeter. See

Table 30 for correct outdoor sensor resistance.

3. Replace the outdoor sensor.

NOTE:

If an outdoor sensor IS NOT used in the installation, enter the System Setting Program Navigation, go to Function 21, and turn the setting from

ON to OFF.

The following blocking codes will block operation until the control determines the situation safe for boiler operation.

Blocking Code E07

FLUE TEMP HIGH E07

PUMP OFF TIME

This display indicates that the flue sensor tem-

perature is excessive and above 210

o

F. When

this code is displayed, the boiler will not respond

to a demand for heat. When the flue temperature

decreases below 194

o

F, the display will return to

normal and allow the boiler to respond to a heat

demand. The bottom line indicates the status of

the pump. The pump will remain off when this

error is displayed.

Check the flue for obstructions or any sign of damage, especially

signs of excessive heat. Repair as necessary. Run the boiler and

check the flue temperature with an external thermometer. If the flue

temperature on the thermometer does not agree with the flue

temperature displayed in the status menu, inspect the wiring to the

flue temperature sensor in the boiler and repair as necessary. If the

wiring is intact, replace the flue sensor. If the flue temperature is

excessive on the status menu and the test thermometer reads the

same, check and adjust combustion controls on the boiler. If the

problem persists, inspect the target wall in the combustion chamber

and replace it if cracked or damaged.

Blocking Code E19

LINE VOLTAGE

PUMP OFF E19

This display indicates that the line voltage fre-

quency is out of range. This could happen if the

boiler is being powered from a small gasoline

powered generator that is not functioning cor-

rectly or overloaded.

Inspect power wiring to boiler and repair as necessary. If connected

to line voltage, notify the power company. If connected to an

alternate power source such as generator or inverter, make sure the

line voltage frequency supplied by the device is 60 Hz.

Table 29

– Fault and Blocking Code Screens

Summary of Contents for WBCNG399W

Page 14: ...14 WHL 016 REV 12 18 14 SPECIFICATIONS AND DIMENSIONS Figure 2 Specifications and Dimensions ...

Page 24: ...24 WHL 016 REV 12 18 14 Figure 8 Piping Symbol Legend ...

Page 59: ...59 WHL 016 REV 12 18 14 Figure 32 Cascade Master and Follower Wiring ...

Page 60: ...60 WHL 016 REV 12 18 14 Figure 33 Internal Connection Diagram LP 293 J ...

Page 83: ...83 WHL 016 REV 12 18 14 055 080 110 PARTS BREAKDOWN Figure 36 Replacement Parts LP 387 J ...

Page 85: ...85 WHL 016 REV 12 18 14 155 199 285 399 PARTS BREAKDOWN ...

Page 86: ...86 WHL 016 REV 12 18 14 Figure 38 Replacement Parts LP 387 KK ...

Page 87: ...87 WHL 016 REV 12 18 14 155 199 285 399 MODEL PARTS BREAKDOWN ...

Page 91: ...91 WHL 016 REV 12 18 14 ...

Page 92: ...92 WHL 016 REV 12 18 14 ...