80

WHL-016 REV. 12.18.14

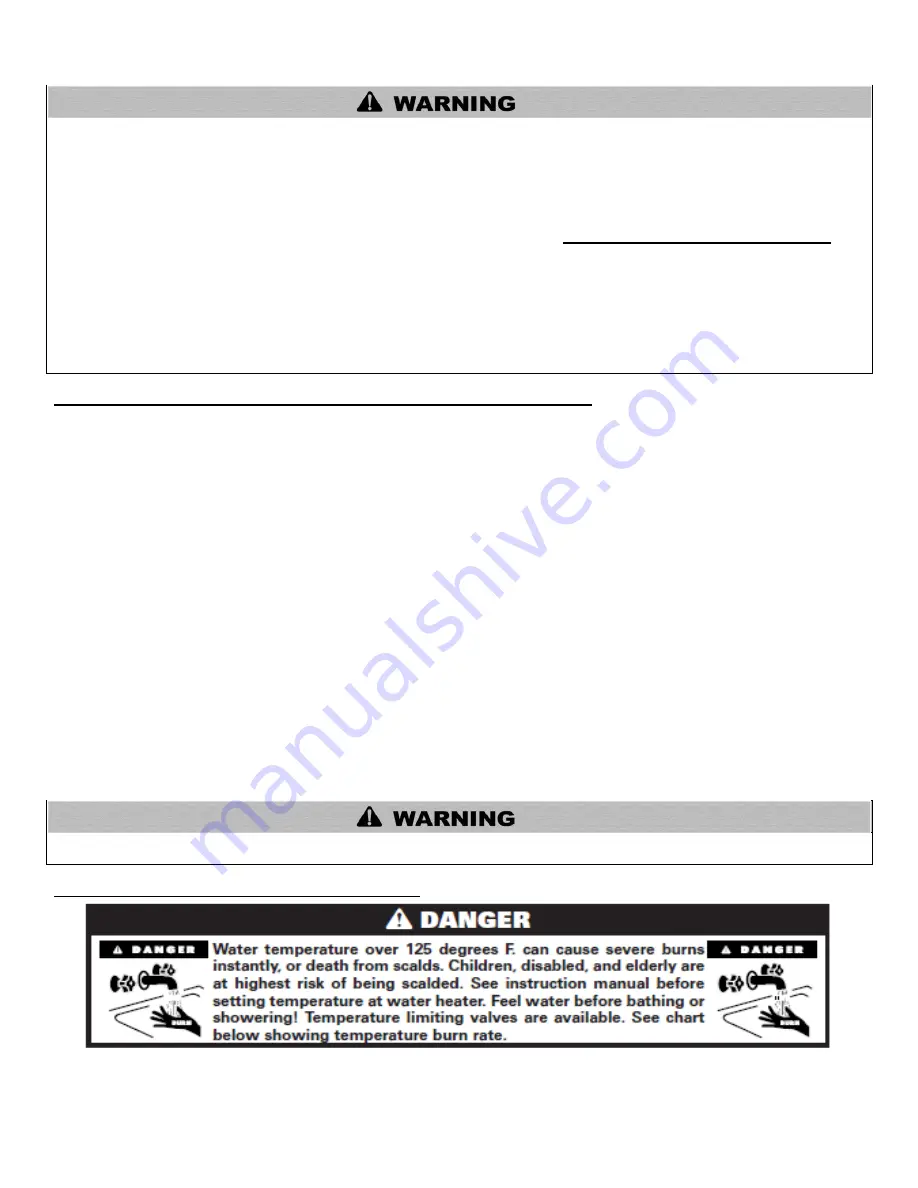

The combustion chamber insulation in this product contains ceramic fiber material. Ceramic fibers can be converted to

cristobalite in very high temperature applications. The International Agency for Research on Cancer (IARC) has concluded,

“Crystalline silica inhaled in the form of quartz or cristobalite from occupational sources is carcinogenic to humans (Group

1).”

Avoid breathing dust and contact with skin and eyes.

Use NIOSH certified dust respirator (N95). This type of respirator is based on the OSHA requirements for cristobalite

at the time this document was written. Other types of respirators may be needed depending on job site conditions.

Current NIOSH recommendations can be found on the NIOSH website: http://www.cdc.gov/niosh/homepage.html.

NIOSH approved respirators, manufacturers, and phone numbers are also listed on this website.

Wear long-sleeved, loose fitting clothing, gloves, and eye protection.

Apply enough water to the combustion chamber lining to prevent dust.

Wash potentially contaminated clothes separately from other clothing. Rinse clothes washer thoroughly.

NIOSH stated First Aid.

Eye: Irrigate immediately.

Breathing: Fresh air.

B. COMBUSTION CHAMBER COIL CLEANING INSTRUCTIONS FOR BOILER

*Before beginning this procedure, you must have on hand the following items:

a nylon brush

NOTE:

Do not use a metal brush on the heat exchanger. Doing so could scratch the heat exchanger, and lead to early boiler

failure. Such failure IS NOT covered by warranty.

an FDA approved liquid lime scale remover for use with stainless steel, or water, in a spray bottle

gloves and eye protection

1. Shut down the Boiler by using the following steps:

a. Turn off power to the boiler. Turn thermostats down to ensure there is no call for heat, or disconnect thermostat connections

from terminals. Close the gas valve inside the boiler cabinet. Wait for the boiler to be cool to the touch.

b. Disconnect the wires plugged into the fan, spark electrode, flame rod, and gas valve.

c. Disconnect the flexible gas lines from the venture attached to the fan.

d. Loosen the nuts that hold the burner plate to the heat exchanger.

e. Remove the combustion assembly.

f. Spray water or solution into the combustion assembly and monitor the flow through the combustion system.

g. Liquid should flow freely through each tube. If there is an obstruction, increase the flow on the tube to force blockage out.

h. Once complete, reinstall combustion assembly with gaskets and secure nuts. Tighten properly.

i. Reconnect all wire and piping connections. Once connected, apply power and disconnect the wire harness with the white-

blue-red-black wires to run fan and dry combustion assembly. Let fan run for five minutes. When finished, reconnect harness

to the fan.

j. Connect the thermostat wires to the field connection board, or turn up thermostat to fire the combustion system. Check for

leaks in the combustion system. Observe operation for 5 to 10 minutes.

If boiler is operating properly, condensate is flowing normally, and no gas leaks are detected, combustion coil cleaning is complete.

Do not use solvents to clean any of the burner components. The components could be damaged, resulting in unreliable or unsafe

operation. Failure to do so could result in death or serious injury.

C. CLEANING WATER SIDE OF HEAT EXCHANGER

1. Make sure power is turned off to the boiler. Run water through the hot water system to assure it is below room temperature.

Summary of Contents for WBCNG399W

Page 14: ...14 WHL 016 REV 12 18 14 SPECIFICATIONS AND DIMENSIONS Figure 2 Specifications and Dimensions ...

Page 24: ...24 WHL 016 REV 12 18 14 Figure 8 Piping Symbol Legend ...

Page 59: ...59 WHL 016 REV 12 18 14 Figure 32 Cascade Master and Follower Wiring ...

Page 60: ...60 WHL 016 REV 12 18 14 Figure 33 Internal Connection Diagram LP 293 J ...

Page 83: ...83 WHL 016 REV 12 18 14 055 080 110 PARTS BREAKDOWN Figure 36 Replacement Parts LP 387 J ...

Page 85: ...85 WHL 016 REV 12 18 14 155 199 285 399 PARTS BREAKDOWN ...

Page 86: ...86 WHL 016 REV 12 18 14 Figure 38 Replacement Parts LP 387 KK ...

Page 87: ...87 WHL 016 REV 12 18 14 155 199 285 399 MODEL PARTS BREAKDOWN ...

Page 91: ...91 WHL 016 REV 12 18 14 ...

Page 92: ...92 WHL 016 REV 12 18 14 ...