Westinghouse Outdoor Power Equipment, LLC | 27

MAINTENANCE

SHORT TERM STORAGE

• Allow the generator to cool a minimum of 30 minutes

before storage.

• If operating on propane, turn the propane tank valve

to the fully closed position and disconnect the LPG/

propane hose from the generator and propane tank.

• Replace all protective covers on the generator control

panel.

• Wipe the generator with a moist cloth. Clean any debris

from the muffler cooling vents.

• Store the generator in a well-ventilated, dry location

away from sparks, open flames, pilot lights, heat, and

other sources of ignition such as areas with a spark-

producing electric motor or where power tools are

operated.

• Do not store the generator, gasoline, or propane tanks

near furnaces, water heaters, or any other appliances

that produce heat or have automatic ignitions.

• With the engine and exhaust system cool and all

surfaces dry, cover the generator to keep out dust. Do

not use a plastic sheet as a dust cover. Non-porous

materials trap moisture and promote rust and corrosion.

LONG TERM STORAGE

Even properly stabilized fuel can leave residue and cause

corrosion if left long term. If storing the generator for over

six months, drain the fuel tank.

DRAINING THE FUEL TANK

If storing the generator for longer than six months, drain

the fuel tank to prevent fuel separation, deterioration, and

deposits in the fuel system.

1.

Unscrew the fuel tank cap. Remove the fuel screen filter

by slightly compressing it while removing it from the

tank.

2.

Using a commercially available gasoline hand pump

(not included), siphon the gasoline from the fuel tank

into an approved gasoline container. DO NOT use an

electric pump.

OR

Disconnect the fuel line from the bottom of the fuel tank

and allow the fuel to drain into an approved gasoline

container. Reinstall the fuel line.

3.

Reinstall the fuel screen filter and the fuel tank cap.

4.

Start the generator and allow it to run until the generator

engine stops.

5.

Push the battery switch to the OFF position.

6.

Disconnect the battery.

VALVE CLEARANCE

NOTICE

Checking and adjusting valve clearance must be done

when the engine is cold.

Perform this procedure on both cylinders.

1.

Remove the rocker arm cover and carefully remove

the gasket. If the gasket is torn or damaged, it must be

replaced.

2.

Remove the spark plug so the engine can be rotated

more easily.

3.

Rotate the engine to Top Dead Center (TDC) by

momentarily pushing the Start button. Looking through

the spark plug hole, the piston should be at the top (both

valves are closed).

4.

Both the rocker arms should be loose at TDC on the

compression stroke. If they are not, rotate the engine

360°.

5.

Insert a feeler gauge between the rocker arm and the

valve stem to measure valve clearance.

Intake Valve

Exhaust Valve

Valve Clearance

0.0031 – 0.0047 in

(0.08 – 0.12 mm)

0.0051 – 0.0067 in

(0.13 – 0.17 mm)

Torque

8-12 N•m

8-12 N•m

6.

If an adjustment is necessary, hold the rocker arm pivot

and loosen the pivot adjusting nut.

7.

Turn the rocker arm pivot to obtain the specified

clearance. Hold the rocker arm pivot and re-tighten the

pivot adjusting nut to the specified torque.

Torque: 106 inch-pound (12 N•m)

8.

Perform this procedure for the other valve.

9.

Install the gasket, rocker arm cover, and spark plug.

Summary of Contents for WGen12000DF

Page 8: ...8 Westinghouse Outdoor Power Equipment LLC SAFETY SAFETY LABELS AND DECALS...

Page 9: ...Westinghouse Outdoor Power Equipment LLC 9 COMPONENTS COMPONENTS GENERATOR COMPONENTS...

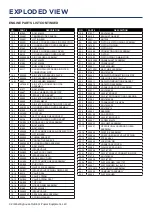

Page 33: ...Westinghouse Outdoor Power Equipment LLC 33 EXPLODED VIEW GENERATOR EXPLODED VIEW...

Page 36: ...36 Westinghouse Outdoor Power Equipment LLC SCHEMATICS SCHEMATICS...