22 | Westinghouse Outdoor Power Equipment, LLC

4.

Loosen the float bowl drain screw and allow the fuel to

drain. Tighten the float bowl drain screw.

DRAINING THE FUEL TANK

If storing the generator for longer than six months, drain

the fuel tank to prevent fuel separation, deterioration, and

deposits in the fuel system.

1.

Unscrew the fuel tank cap. Remove the fuel screen filter

by slightly compressing it while removing it from the

tank.

2.

Using a commercially available gasoline hand pump

(not included), siphon the gasoline from the fuel tank

into an approved gasoline container.

DO NOT

use an

electric pump.

3.

Reinstall the fuel screen filter and the fuel tank cap.

4.

Start the generator and allow it to run until the generator

engine stops.

5.

Push the Run/Stop switch to the Stop position.

6.

Remove the spark plug.

7.

Put a teaspoon of engine oil into the cylinder and pull the

recoil handle until resistance is felt. At this position the

piston is coming up on its compression stroke and both

valves are closed. Storing the engine in this position will

help prevent internal corrosion. Return the recoil handle

gently.

8.

Reinstall the spark plug. Leave the spark plug boot

disconnected to prevent accidental starting.

FUEL VALVE MAINTENANCE

The fuel valve is equipped with a fuel sediment cup, screen,

and o-ring. The fuel valve does not require servicing if the

unit is properly maintained with fresh, clean fuel. If fuel-

related troubleshooting is required, perform fuel valve

maintenance.

1.

Allow the generator to cool completely.

2.

Turn the fuel valve to the OFF position.

3.

Remove the sediment cup from the fuel valve. Remove

the o-ring and screen.

Fuel valve

Screen

O-ring

Cup

4.

Wash the sediment cup, o-ring, and screen in a

nonflammable solvent. Dry thoroughly.

5.

Place the screen and o-ring into the fuel valve. Install

the sediment cup and tighten securely.

6.

Turn the fuel valve to the ON position and check for

leaks. Replace the fuel valve if there is any leakage.

7.

Turn the fuel valve to the ON position and check for

leaks. Replace the fuel valve if there is any leakage.

VALVE CLEARANCE

NOTICE

Checking and adjusting valve clearance must be done

when the engine is cold.

1.

Remove the rocker arm cover and carefully remove

the gasket. If the gasket is torn or damaged, it must be

replaced.

2.

Remove the spark plug so the engine can be rotated

more easily.

3.

Rotate the engine to top dead center (TDC) by pulling

the recoil handle slowly. Looking through the spark plug

hole, the piston should be at the top (both valves are

closed).

4.

Both the rocker arms should be loose at TDC on the

compression stroke. If they are not, rotate the engine

360°.

5.

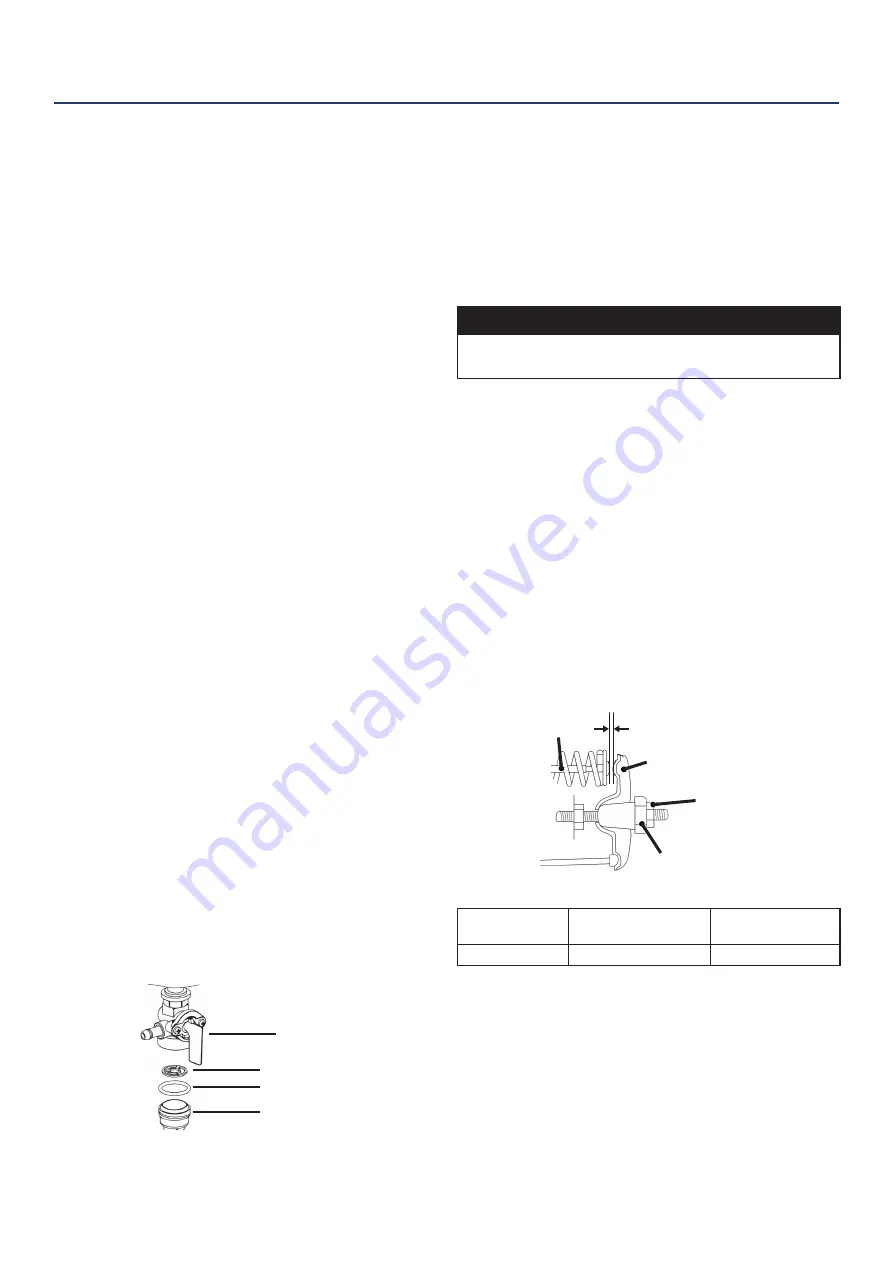

Insert a feeler gauge between the rocker arm and the

valve stem to measure valve clearance.

Pivot

Adjusting Nut

Valve Stem

Rocker Arm

Rocker Arm Pivot

Intake Valve

Exhaust Valve

Valve Clearance

0.0031 – 0.0047 in

(0.08 – 0.12 mm)

0.0051 – 0.0067 in

(0.13 – 0.17 mm)

Torque

8-12 N•m

8-12 N•m

6.

If an adjustment is necessary, hold the rocker arm pivot

and loosen the pivot adjusting nut.

7.

Turn the rocker arm pivot to obtain the specified

clearance. Hold the rocker arm pivot and re-tighten the

pivot adjusting nut to the specified torque.

Torque: 106 inch-pound (12 N•m)

8.

Perform this procedure for the other valve.

9.

Install the gasket, rocker arm cover, and spark plug.

MAINTENANCE