Westinghouse Portable Power | 23

MAINTENANCE

CLEANING THE SPARK ARRESTOR

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

Check and clean the spark arrestor after every 100 hours

of use or 6 months.

1. Generator must be cold to perform this maintenance.

2.

Move the inverter to a flat, level surface.

3.

Remove the 6 screws holding the muffler cover in

place (see Figure 15).

Figure 15: Remove screws holding muffler cover

4. Once the cover is removed, locate the screw on the

tip of the muffler and remove. Pull the spark arrestor

out of the muffler. (see Figure 16).

Figure 16: Remove spark arrestor

5. If the spark arrestor screen shows signs of wear (rips,

tears or large openings in the screen), replace the

spark arrestor screen.

NOTE:

Only use Westinghouse

spark arrestors as replacements.

6. If screen is not torn then clean using a wire brush,

commercial solvent, or compressed air. Remove any

dirt and debris that may have collected on the spark

arrestor screen (see Figure 17).

Figure 17: Clean spark arrestor

7.

Install the spark arrestor back into the muffler. Make

sure to fully push it in so that it is tight on the tip of

the muffler.

8. Replace the muffler cover and tighten all 6 screws.

DRAINING CARBURETOR FLOAT BOWL

1.

Make sure the generator is off and you are away from

any open flames.

2.

Place pan (or suitable

container) under the

carburetor assembly.

3.

Loosen screw at bottom of

the bowl and allow gas to

drain out.

4.

After all the gas has drained

out, tighten the screw.

fuel pan

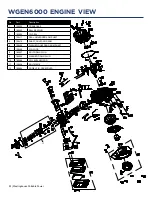

Summary of Contents for WGen6000

Page 1: ...USER MANUAL WGen6000 Portable Generator 6000 Running Watts 7500 Peak Watts...

Page 8: ...8 Westinghouse Portable Power SAFETY SAFETY LABELS AND DECALS 8 7 10 8 9 6 6 7 5 10 9...

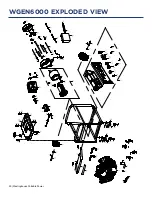

Page 30: ...30 Westinghouse Portable Power WGEN6000 EXPLODED VIEW...

Page 34: ...34 Westinghouse Portable Power WGEN6000 SCHEMATIC WH7500v SCHEMATIC...

Page 36: ...36 Westinghouse Portable Power Version 08 10 18KD...