24 | Westinghouse Portable Power

Cleaning the Air Filter

- Continued from Page 23

NOTICE

Never dispose of soap cleaning solution used to clean the air filter

by dumping the solution into a sewer, on the ground, or into ground

water or waterways. Always be environmentally responsible.

Follow the guidelines of the EPA or other governmental agencies

for proper disposal of hazardous materials. Consult local

authorities or reclamation facility.

1.

Dispose of used soap cleaning solution properly.

2.

Dry the air filter elements by again applying a slow

firm squeezing action.

3.

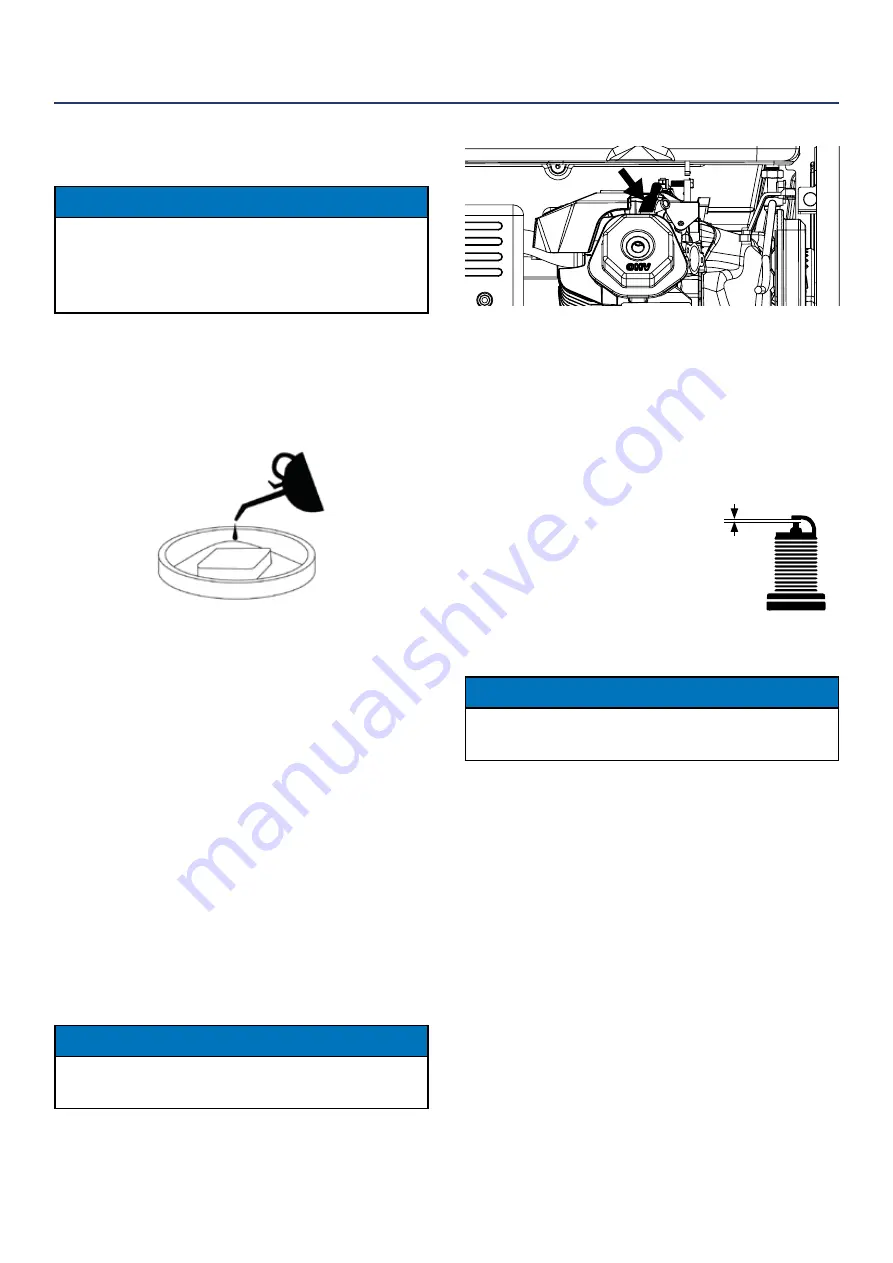

Once the air filters are dry, coat the air filters with

clean engine oil (see Figure 19 below).

Figure 19

4. Squeeze the filters to remove any excess oil.

5. Install the filters back into the unit. If there are two

filters make sure the gray (fine) air filter goes in

first followed by the black (coarse) air filter on the

outside.

6. Install the air filter cover and secure the air filter assembly.

SPARK PLUG MAINTENANCE

The spark plug must be checked and cleaned after

every 100 hours of use or 6 months and must be

replaced after 300 hours of use or every year.

1.

Stop the generator and let it cool for several

minutes if running.

2.

Move the generator to a flat, level surface.

3.

Remove the spark plug boot by firmly pulling the

plastic spark plug boot handle directly away from

the engine (see Figure 20).

NOTICE

Never apply any side load or move the spark plug laterally when

removing the spark plug. Applying a side load or moving the spark

plug laterally may crack and damage the spark plug boot.

Figure 20

- Remove Spark Plug Boot

4. Clean area around the spark plug.

5. Using the 13/16” spark plug socket wrench

provided, remove the spark plug from the cylinder

head.

6. Place a clean rag over the opening created by the

removal of the spark plug to make sure no dirt can

get into the combustion chamber.

• Inspect the spark plug for:

•

Cracked or chipped insulator

•

Excessive wear

•

Spark plug gap (the acceptable

limit of 0.027–0.032 in.

[0.70 – 0.80 mm]) (see Figure 21).

NOTICE

Use only recommended spark plugs when servicing. The

manufacturer is not responsible for engine damage when using

spark plugs not recommended by the manufacturer.

7.

Install the spark plug by carefully following the

steps outlined below:

a.

Carefully insert the spark plug back into the

cylinder head. Hand-thread the spark plug until

it bottoms out.

b.

Using the 13/16” spark plug socket wrench

provided, turn the spark plug to ensure it is fully

seated.

c. Replace the spark plug boot, making sure the

boot fully engages the spark plug’s tip.

Recommended Spark Plug Replacement:

AC Delco: 4EXLS

Autolite: 52

Champion: N9YC

Bosch: W7DC

Torch: F7TC

MAINTENANCE

SPARK PLUG GAP

Figure 21

Summary of Contents for WH10000

Page 1: ...USER MANUAL WH10000 Portable Generator 8000 Running Watts 10000 Peak Watts...

Page 8: ...8 Westinghouse Portable Power SAFETY SAFETY LABELS AND DECALS 8 7 10 8 9 6 6 7 5 10 9...

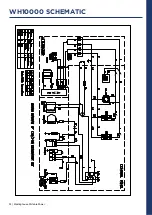

Page 32: ...32 Westinghouse Portable Power WH10000 SCHEMATIC...

Page 33: ...Westinghouse Portable Power 33 Version 12 17 18KD...