B E L 1 8 0 S E M I - A U T O M A T I C R A N D O M T A P E S E A L E R

2

Introduction

The BEL 180 is capable of applying pressure-sensitive tape to both the top and bottom of various

size cases presented to the machine at random or without manual adjustment between sizes. In

addition, the machine features the ability to use the random function to automatically adjust to a

uniform case size and lock itself in position for longer runs of a single case size.

The features of the BEL 180 are:

DEKKA CADET - 2” high performance tape heads

A special sensor system that activates the dynamic case height adjustment while eliminating a

potential pinch point. Moving parts are concealed by design and by guarding to a high

standard of safety

A stainless steel controls enclosure with logic controller and a second conveniently placed

start/stop switch at the front of the top tapehead holder. There is a solenoid valve as well as a

manual valve for compressed air supply.

Roller infeed section for easier case entry

A robust vertical actuator system for moving the top drive and tape head. It uses air cylinders

with pneumatic rod locks to secure the random case size adjustments, lock the machine in

position for uniform case sizes in ‘Lock’ mode and for safety to prevent unexpected

movement in the case of a sudden electrical or pneumatic power failure.

A tilt-up bottom tapehead holder for easier access to replace the tape roll or remove the

bottom tapehead from the machine.

Heavy duty stainless steel frame.

Interlocked enclosure guard doors.

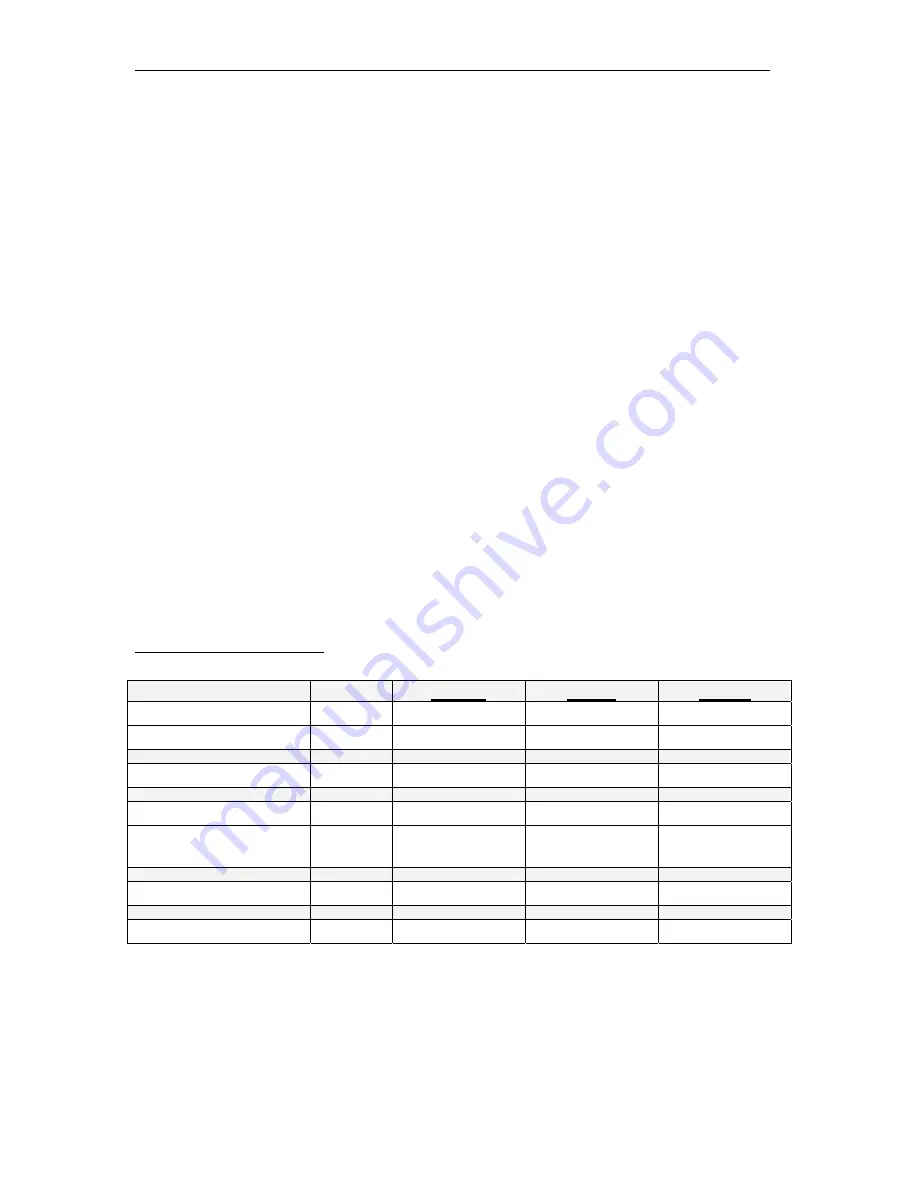

Standard Specifications:

Length

Width

Height

Case Size Range

Minimum

6” / 152mm

6” / 152mm

6” / 152mm

Maximum

72” / 1829mm*

17” / 432mm

19” / 483mm

*can be made longer

Machine Dimensions

46” / 1175mm

36” / 889mm

54” / 1372mm

In/Outfeed Height

Frame

23.5” / 597mm

With adjustable leg extensions

[foot pad]

Minimum

Maximum

23.5" / 597mm

30” / 762mm

Speed

Up to 10 cases / min.

Shipping Weight

Approx.

500 lbs. / 227 kg.

For further detail, see Layout Drawing 75-678

65-34-5 4/21/10