6

Assembly Instructions

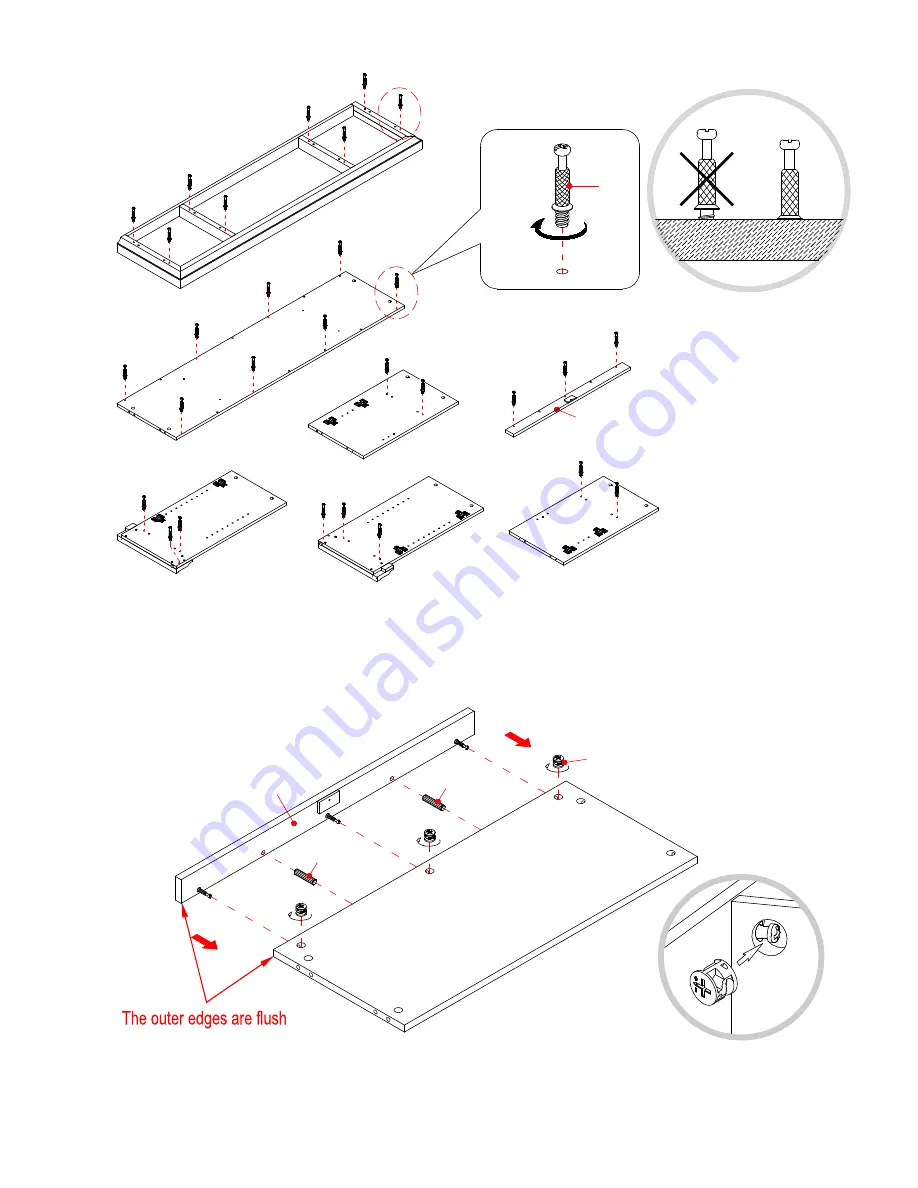

1.

Unpack the unit and confirm that you have all the hardware and required parts. Assembly the unit on a

carpeted floor or the empty carton to avoid any scratch.

2.

Securely screw the Cam Bolts (2) into the designated small holes on the Panels (A, B, G, H, I and J) and

the Middle Crossbar (F) using a Phillips screwdriver, as shown in the illustration.

3.

Align and attach the Middle Crossbar (F) to the Fixed Shelf (E) with two Wood Dowels (3) and three

Cam Locks (1) (Refer to page 3 on Cam Lock system operation supplement). Tap in with a rubber

mallet, if necessary. Make sure that you use a small amount of glue with both ends of all dowels.

3

3

E

F

1

A

B

H

G

I

J

F

2